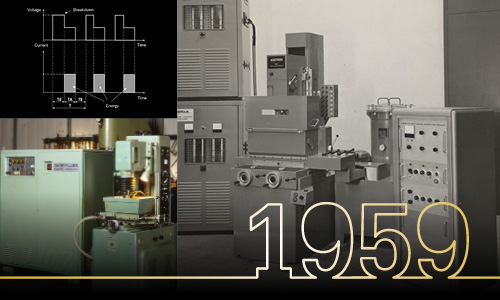

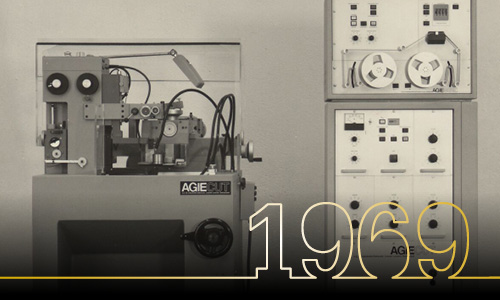

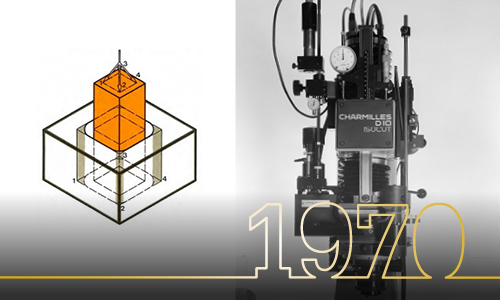

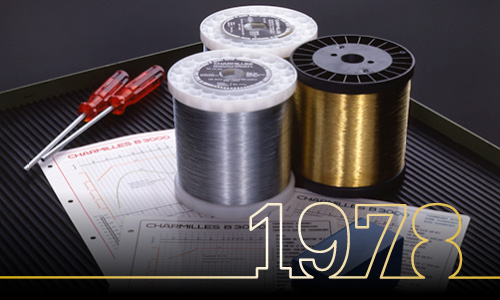

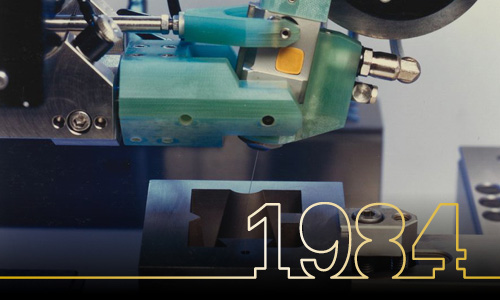

Writing EDM history since 1954

Welcome to our 70th anniversary celebration! As pioneers in EDM manufacturing, we're proud of our rich history and ongoing innovation. From aerospace to automotive, we've led with cutting-edge technologies, revolutionizing industries worldwide.

For seven decades, our dedication to top-quality EDM solutions has made us a trusted partner for businesses improving their manufacturing. From pioneering techniques to tailored solutions, our journey is about excellence and customer satisfaction. Join us in celebrating our achievements and anticipating even greater success in EDM.

Please accept all cookies to view the external content.

Please accept all cookies to view the external content.

Please accept all cookies to view the external content.

Technology overview

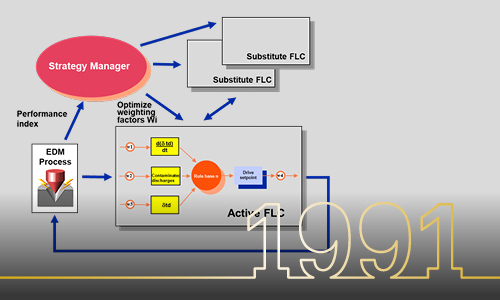

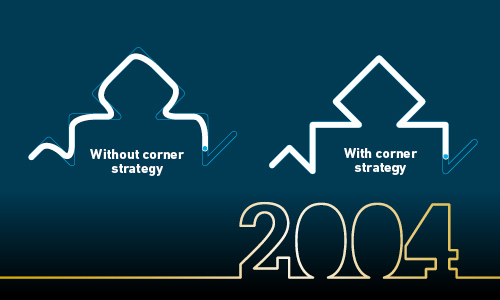

GF Machining Solutions introduces cutting-edge solutions in Die-sinking electrical discharge machining alongside our advanced Wire-cutting EDM systems. Our EDM solutions are renowned for their speed, precision, and energy efficiency, catering to diverse machining needs from miniaturized components to high-speed applications with superior surface accuracy.

In industries ranging from automotive to medical devices, our technology plays a pivotal role in achieving manufacturing excellence. With GF Machining Solutions, manufacturers can elevate their capabilities and achieve remarkable success in various industries.

Please accept all cookies to view the external content.

Please accept all cookies to view the external content.