Programming of Blades and blisks/IBR’s

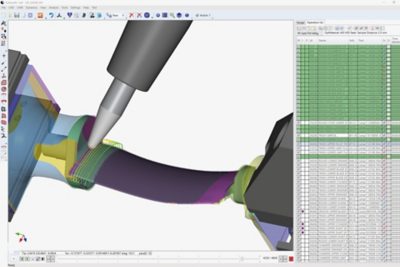

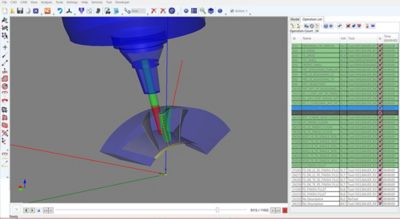

Spiral milling of airfoils with 5-axis simultaneous machining technology including the machining of hub and shroud features in order to finish a turbine blade or blisk in one set-up.

Radial and side entry 5 axis ultra-dynamic point milling of blisks from sonic shapes or adaptive milling of friction weldments and airfoil midspans.

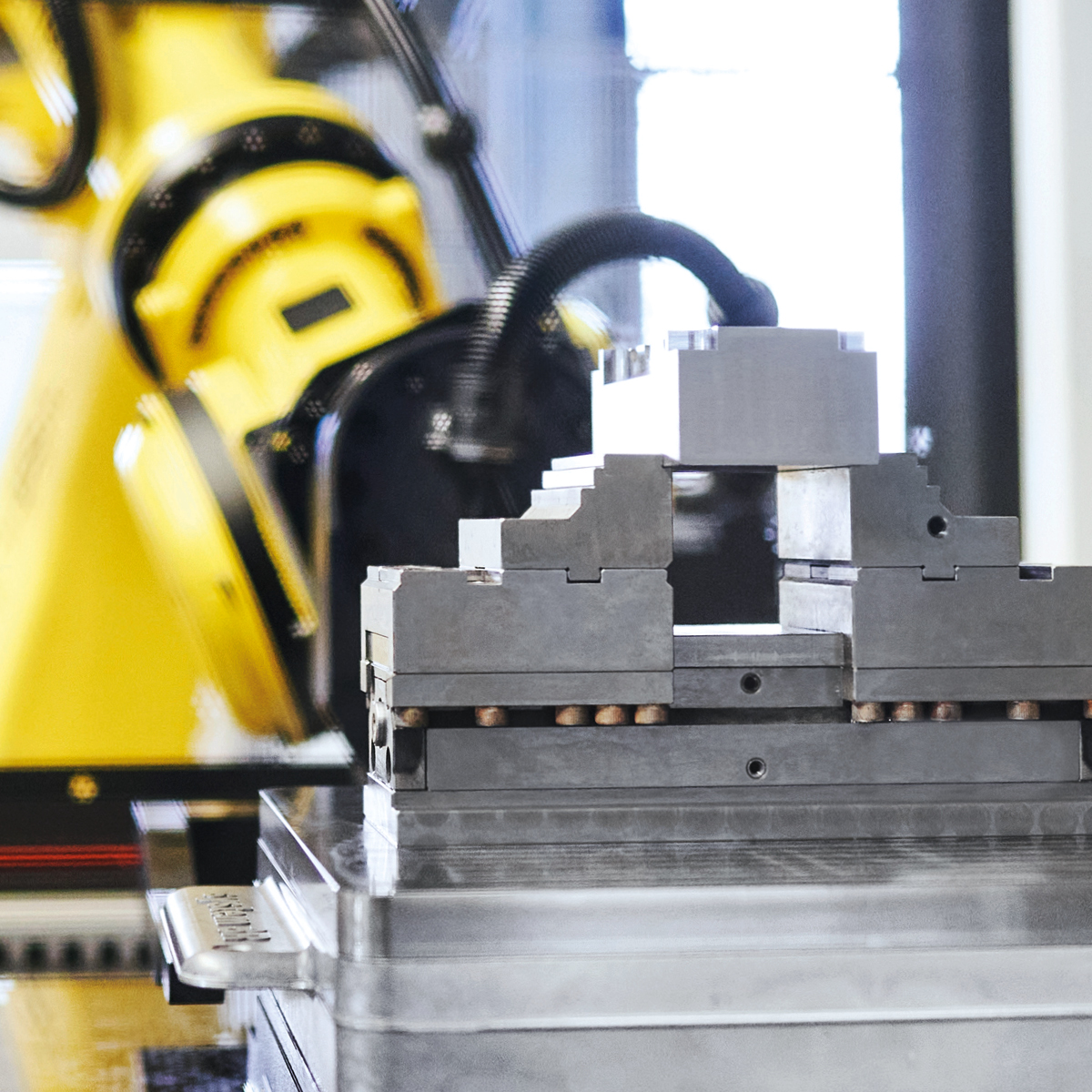

Solutions from one single source. Extensive airfoil machining experience and CAM programming expertise is available at the LIECHTI CAM department – a team of specialists directly accessible to you to support performance improvements in your airfoil production.

Turbosoft with its specialized strategies makes our knowhow accessible to you.

The system has the following characteristics:

- The consequent machining process for airfoils (blades, blisks) is defined with time savings and high quality

- Graphical interactive user interface, parametric definition of machining operations

- Consistent data storage of TURBOSOFT plus job

- Fully integrated free-form surfaces

- Surface modelling facilities for turbo machinery applications including spline fitting, enveloping, patching and edge fitting

- Interface for IGES and PARASOLID formatted data

- Advanced machining strategies to optimize surface finish quality and to reduce machining times

- Roughing strategies based on remaining material condition

- No hand finishing required

- Checking and avoiding undercut in sturz milling applications

- Supports a wide variety of tools e.g. conical ball ended and toroid end mills

- Integrated postprocessors