Discover the accelerating shift towards New Energy Vehicles (NEVs) propelled by governmental mandates for carbon neutrality, as GF Machining Solutions offers field-proven solutions and technologies, securing your position and maintaining your competitive edge amidst the dynamic market of hybrid, battery, and fuel cell energy vehicles.

A range of solutions for your applications

Please accept all cookies to view the external content.

Please accept all cookies to view the external content.

Battery modules

Please accept all cookies to view the external content.

Batteries are at the heart of different types of NEV powertrains. Battery management systems with inverters translate power smoothly and safely, whereas the cooling of battery housings and inverter housings is critical. Manufacturing of these crucial elements requires precise molds for the production of housings and castings.

- Produce with high precision on any type of material such as silicon carbides and ceramics

- Benefit from the possibility to connect between technologies without compromising accuracy

- Keep your competitiveness with long-term quality and reliability

Domain controllers and micro connectors

Please accept all cookies to view the external content.

Automotive electrical architecture is moving from flat to domain-controlled modules and high-level zonal control modules. This implies implementing several autonomous levels and reducing lag in communications. As a consequence, the number of micro control units (MCU) and zonal electronic control units (ECU) increase. Supply chains must support this migration and the production volumes that are involved.

- Realize micro molds with reliable solutions

- Achieve sharp corners and profiles

- Simplify programming and ease operation

- Secure manufacturing of a wide range of products with 24/7 unmanned production

TRUE, an intelligent solution for connector manufacturing

Please accept all cookies to view the youtube video content.

Charging units

An essential infrastructure for NEV, charging units are designed with cooling channels for user safety and efficient charging. Providing high power while being able to withstand heat and long cycles, they contain micro connectors with high-performance sealing so as to avoid any leakage. Housings of these charging units are often made out of hard plastic materials reinforced with glass fibers, while connectors need precision for a perfect contact and self-lock.

- Achieve high precision of small geometries with lowest wear on electrodes

- Benefit from our FORM eCAM programming software, specifically designed for EDM, to seamlessly go from CAD to machining

- Combine our Milling and Wire EDM technologies to produce a wide range of designs and volumes

- Our Wire EDM solutions secure the production of complex molds with the optional System 3R indexing unit

- The EDM unique 3DS surface ensures perfect textures on recycled plastic materials and particular VDI requirements

- Our integrated Automation solutions allow for 24/7 unattended manufacturing

- The unique graphite (GR3) solutions provide flexibility to mold makers

- Machine a wide range of precision electrode materials, such as copper, tungsten-copper or graphite, with conventional molds on the same machine

- With either standalone or automated solutions, secure your productivity and efficiency with our standardized System 3R toolings

Bipolar plate for hydrogen powertrain

Hydrogen powertrain is a mobility solution that is gradually gaining momentum, backed by governmental subsidies. Producing power from hydrogen and oxygen supplied into it, stacks are made of thinly stamped or embossed metal alloy sheets with thickness ranging from 0.04 mm to 0.12 mm. Typically, producing bipolar plates for hydrogen powertrain require mold tooling and dies with variation less than 5 μm.

- Advanced ITC functions ensure Z-axis stability over long cycle times

- Step-Tec Spindles provide the lowest vibration and runout, ensuring stable cutting over long cycle times

- Designed with thermo-stabilized polymer concrete construction, our Milling machines ensure long term quality and reliability

Manufacturing challenges

- Achieve best repeatability with small cutting tools over long cutting times with high spindle speeds

- Constant surface quality of complex flow fields and channels geometries

- Achieve constant depth and profile smoothness

Our solutions to overcome these challenges

- Our EDM and Milling technologies provide for high-precision mold manufacturing

- Thermally stable machine structure and in-house Step-tech Spindles ensure stable cutting and extending tool life

- Secure precision down to 5 µm with a uniform finish, thanks to machine stability and programming know-how

Hybrid and EV powertrains

Today NEV powertrain design calls for perfect assembly, generating very low noise with high efficiency. This is a challenge for manufacturing of gear tooling, calling for high precision across increasing production volumes.

- Perfect realization of extremely high accuracy, lower than 4 μm over the whole lifetime of the EDM machine

- Automatic Tool Changer ensures a wide variety for regular production

- Lowest electrode wear thanks in-house designed advanced generators

- Large molds solutions with Milling and Wire-cutting EDM

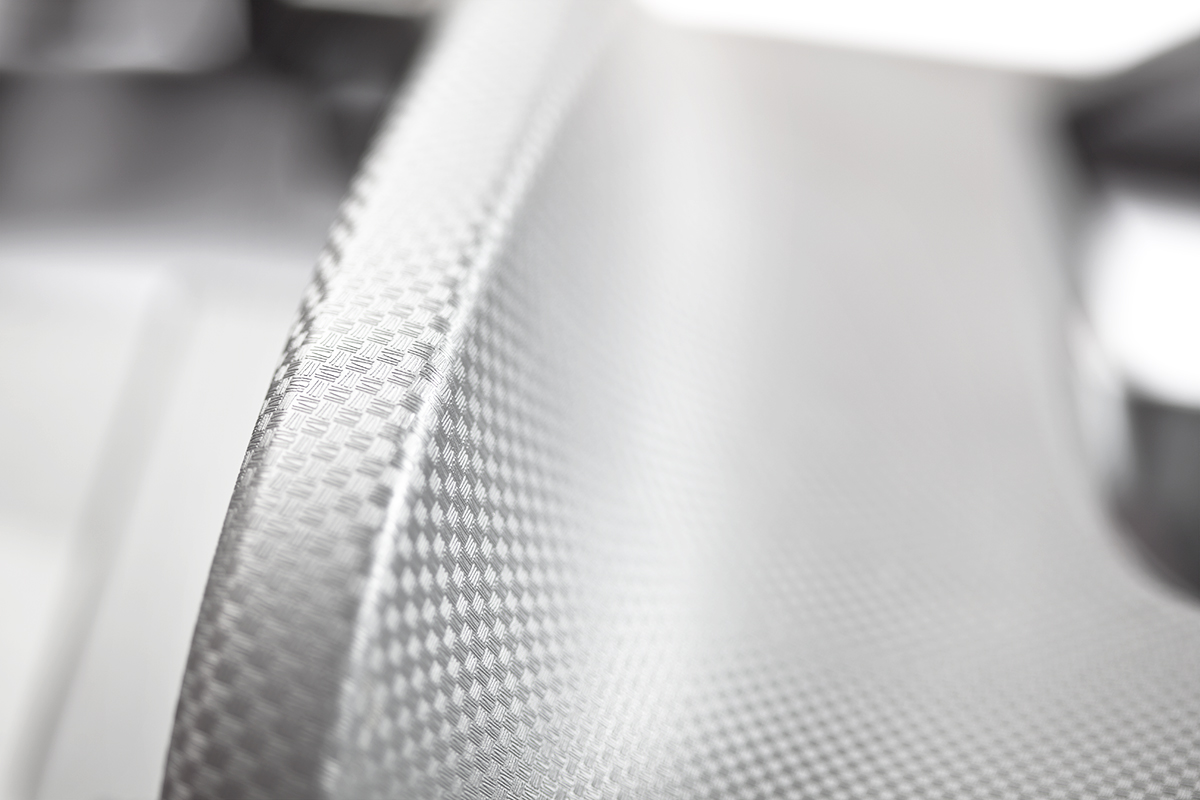

Castings for the drivetrains of hybrid energy, battery-powered and fuel cell energy vehicle are key to ensure smooth transition of power with the lowest noise and the highest durability. These castings require self-cooling designs while presenting unique shapes and deep cavities. Creating mold for these castings is a complicated task and requires many toolings.

- Realize mold inserts and tooling with faster machining rates for economical production

- Combine technologies with ease, for example Milling and EDM

- Stay competitive with long term quality and reliability

- Run your production 24/7 with flexible automated lines connecting all technologies including CMM and wash machines.

Revolutionizing manufacturing: ZEN achieves high quality precision gear dies with our reliable and high-performance FORM X Die-sinking EDM solution

Please accept all cookies to view the youtube video content.

EV motors

EV motors are coupled with different types of hybrid energy vehicle and battery-powered vehicle powertrains. The stamped lamination sheet thickness typically ranges from 0.15 mm to 0.3 mm. A wide range of designs with sharp corners and unique profiles to boost efficiency make it that manufacturing of such parts challenging for mold makers. Today most designs use smaller thickness to reduce stamping machine load thereby reducing power consumption, which raises the need for high-precision molds.

- Opt for our Wire-cutting EDM for high precision and flexibility

- Choose either water or oil tech technologies, each one available with advanced generators

- Produce economically thanks to virtually no wire breakage and faster cuts with ISPS functions

Advanced Wire-cutting EDM technologies for New Energy Vehicles

Please accept all cookies to view the youtube video content.

Testimonials

Extreme Wire and the CUT P 1250

Please accept all cookies to view the youtube video content.