100 years of experience condensed in the best-ever wire EDM machine

-

Extreme accuracy

Optimized mechanics, new 3D-printed heads design and AI-based thermal management are the basis for unprecedented accuracy and surface quality.

-

Simple

It means easy and flexible for experts as for beginners. Thanks to the collision protection, the wire annealing before threading, a new HMI and the option to change from open to closed guides in only few minutes.

-

Fast

We cut at unbeatable speed with the Intelligent Power Generator with Direct Power Supply (IPG-DPS) and the unique Twin-wire technology.

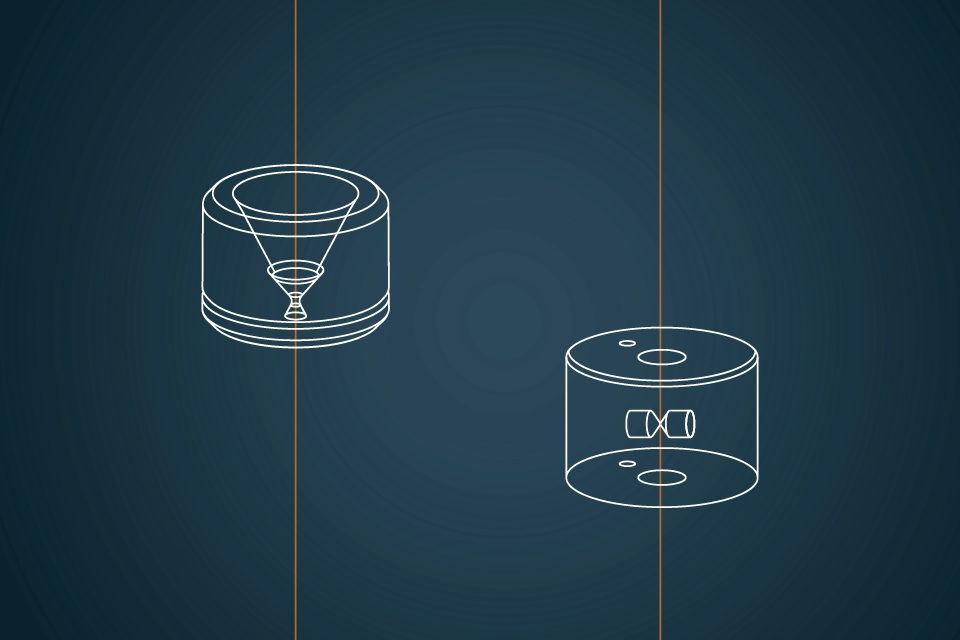

Easily exchangeable open and closed guides

Interchangeable cartridge

The guides are designed as a cartridge that can be easily and quickly exchanged

Maximum flexibility

You can choose the right guide for each different application

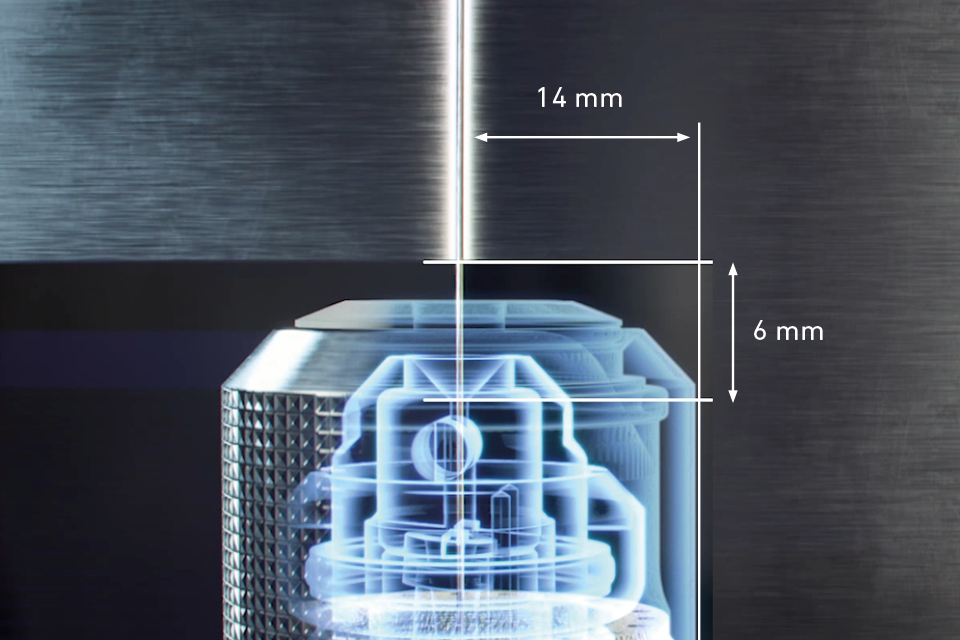

Extreme accuracy

The distance from guide to workpiece is reduced, improving the wire stability.

Clever thermal compensation

AI-based thermal management

Algorithms and sensors predict and reduce thermal impacts and compensates for axis deformation

Ultra high pitch accuracy

Positioning accuracy of +/- 1 micron in environmental temperature changes up to +/- 2,5 Celsius

Twin wire: Automatic Wire Changer (AWC)

AWT: Automatic Wire Threading

Wire annealing

AWT’s annealing process heats the wire between the brake and the lower working head, then chills it with a jet of air and stretches it to reduce its diameter, annealing and extending the wire to a specific length. This produces burr-free thermal cutting and a conically shaped end that is easy to insert through the guides and the workpiece.

Benefits

- Ensure job processing with correct rethreading even under the most difficult conditions

- Automatically cut multiple openings in die blocks and progressive dies during unattended operation

- Enable smooth automation implementation

SMART Wire

SMART wire spools are equipped with radio frequency identification (RFID) chips to store wire characteristics and traceability-related data. This feature equips the CUT X and makes it truly a smart solution!

- Improve your production process

- Achieve full traceability

- Share technical issues in an efficient manner

UNIQUA HMI

UNIQUA is the new GF Machining Solutions human/machine interface (HMI) for wire EDM machines. It represents the pinnacle of more than a century of EDM technology – and the perfect combination of optimal functionality and usability (ergonomics) from our previous HMIs.

Every skill level

UNIQUA is ideal for wire EDM experts and beginners alike. While experts use

its powerful functionalities, beginners can take advantage of its ease-of-use

and short learning curve.

Every approach

UNIQUA works the way you want to work. Control the details of sequential programming with an updated ISO-based functionality or leverage the flexibility of object-oriented programming.

Every user

Work offline or at the machine. UNIQUA ensures compatibility with major CAD/CAM programs and also provides a powerful graphic tool with integrated CAM.

X-Technologies

The X-technologies are a set of cutting technologies perfectly optimized for the CUT X design that condense the all values of the best-ever wire-cutting EDM machine.

Extreme accuracy

The X-technologies are dedicated to obtain ultra-high contour accuracy results thanks to the CUT X minimal distance from guide to work-piece and the revolutionary design of the flushing channels.

Simple

The operator does not need to compromise between accuracy, surface quality or speed. The X-technologies are designed to reach the best results in all 3 features with a unique set of technologies. Simple as that.

The operator just needs to select the wire, the work-piece material, the height, the guiding system (open or closed) and the mono or twin-wire circuit in the UNIQUA HMI. The X-technologies do the rest.

Fast

The X-technologies are also the fastest, ensuring a very high productivity and a short payback of the CUT X machine. And being fast also means being cost-effective sustainable, as the wire consumption is reduced to the minimum.

Sustainability

Discover our innovations that allow our new Wire-Cutting EDM CUT X machine to achieve reductions in daily energy consumption, compared to the previous generation.

Specifications

CUT X 350

| Machine | |

| Type of machining | Submerged wire cutting |

| Dimensions of complete equipment * | 2520 x 2340 x 2154 mm 99.21 x 92.12 x 84.8 in |

| Total weight of the equipment without dielectric | 3900 kg 8598 lbs |

| Machining Area | |

| Work tank | Automatic drop tank |

| Accessibility | Front + Left sides |

| Max. workpiece dimensions * | 800 x 550 x 250 mm 31.49 x 21.65 x 9.84 in |

| Max. workpiece weight without bath | 450 kg 992 lbs |

| Dimensions of table ** | 680 x 450 mm 26.77 x 17.71 in |

| Floor-to-table distance | 1000-1100 mm 39.37-43.3 in |

| Total volume of dielectric fluid | 700 l 185 gal |

| Dielectric level adjustment | 0 – 250 mm (automatic) 0 – 9.84 in (automatic) |

| Dielectric type | Deionized water |

| X, Y, Z and U, V axes | |

| X, Y, Z travel * | 350 x 250 x 256 mm 13.78 x 9.84 x 10.08 in |

| U, V travel ** | ± 70 mm 2.75 in |

| Max. speed (X, Y and U, V axes) | 3 m/min 9.84 ft/min |

| Max. manual position speed | 2 m/min 6.56 ft/min |

| Linear glass scales | Standard on 4 axes (X,Y,U,V) |

| Integrated Collision Protection (ICP) | Standard on 5 axes (X,Y,Z,U,V) |

| Taper machining | |

| Max. taper | 30°/100 mm 3.94 in |

| Electrical supply (machine) | |

| Three-phase input voltage | 400 V ±10% |

| Maximum consumption | 10.4 kVA |

| Compressed air connection | |

| Pressure | 0.6 – 0.8 Mpa 87-116 PSI |

| Maximum consumption | 150 l/min 40 gal/min |

* Width x depth x height ** Width x depth

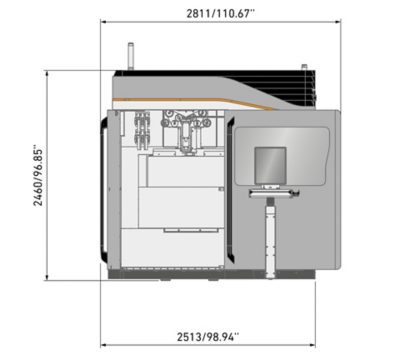

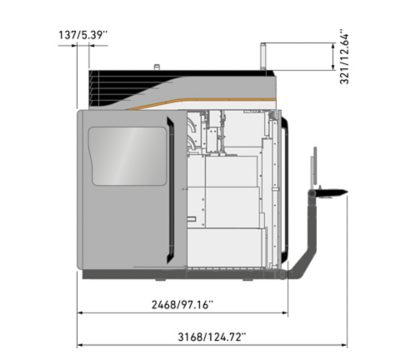

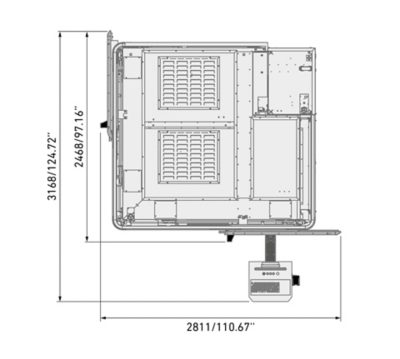

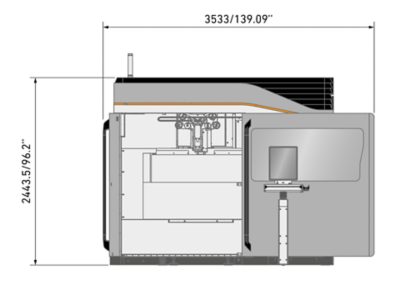

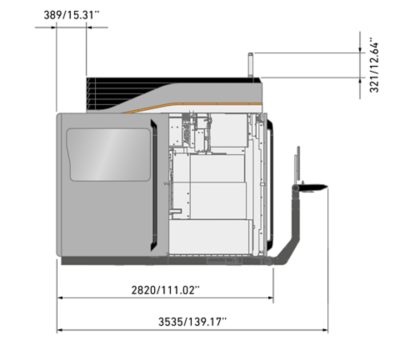

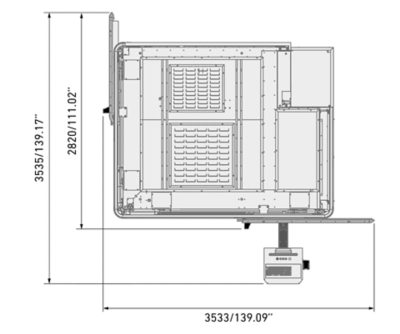

Technical drawings

CUT X 500

| Machine | |

| Type of machining | Submerged wire cutting |

| Dimensions of complete equipment * | 2822 x 3533 x 2444 mm 111.1 x 139.09 x 96.22 in |

| Total weight of the equipment without dielectric | 4700 kg 10362 lbs |

| Machining Area | |

| Work tank | Automatic drop tank |

| Accessibility | Front + Left sides |

| Max. workpiece dimensions * | 1050 x 700 x 250 mm 41.34 x 27.56 x 9.84 in |

| Max. workpiece weight without bath | 800 kg 1764 lbs |

| Dimensions of table ** | 850 x 450 mm 33.46 x 17.71 in |

| Floor-to-table distance | 1000-1100 mm 39.37-43.3 in |

| Total volume of dielectric fluid | 950 l 251 gal |

| Dielectric level adjustment | 0 – 250 mm (automatic) 0 – 9.84 in (automatic) |

| Dielectric type | Deionized water |

| X, Y, Z and U, V axes | |

| X, Y, Z travel * | 500 x 350 x 256 mm 19.68 x 13.78 x 10.08 in |

| U, V travel ** | ± 70 mm 2.75 in |

| Max. speed (X, Y and U, V axes) | 3 m/min 9.84 ft/min |

| Max. manual position speed | 2 m/min 6.56 ft/min |

| Linear glass scales | Standard all axes (X,Y,U,V) |

| Integrated Collision Protection (ICP) | Standard on 5 axes (X,Y,Z,U,V) |

| Taper machining | |

| Max. taper | 30°/100 mm 3.94 in |

| Electrical supply (machine) | |

| Three-phase input voltage | 400 V ±10% |

| Maximum consumption | 10.4 kVA |

| Compressed air connection | |

| Pressure | 0.6 – 0.8 Mpa 87-116 PSI |

| Maximum consumption | 150 l/min 40 gal/min |

* Width x depth x height ** Width x depth

Technical drawings

Video and brochure

CUT X series video

Please accept all cookies to view the youtube video content.