請接受所有 cookies 以檢視外部內容。

累計了 100 多年的技術與經驗,造就有史以來最好的放電加工線切割機

-

極致精準

優化的機械結構、新3D印表機頭設計及人工智能熱能管理實現前所未有的精度和表面粗糙度。

-

簡單

無論是專家還是初學者使用,都是一樣的簡單和靈活。得益於防撞保護、穿線前的燒線系統、新的人機介面 (HMI) 以及可在短短幾分鐘內從開放式眼膜更換為封閉式眼膜的選項。

-

快速

直接供電的智慧型電源箱 (IPG-DPS) 和獨特的雙線技術,能以無與倫比的速度切割。

請接受所有 cookies 以檢視外部內容。

請接受所有 cookies 以檢視外部內容。

易於更換的開放式和封閉式眼膜

互換式眼模系統

卡匣式眼膜設計可輕鬆快速的更換

請接受所有 cookies 以檢視外部內容。

最大靈活性

為不同的應用,選擇正確的眼膜

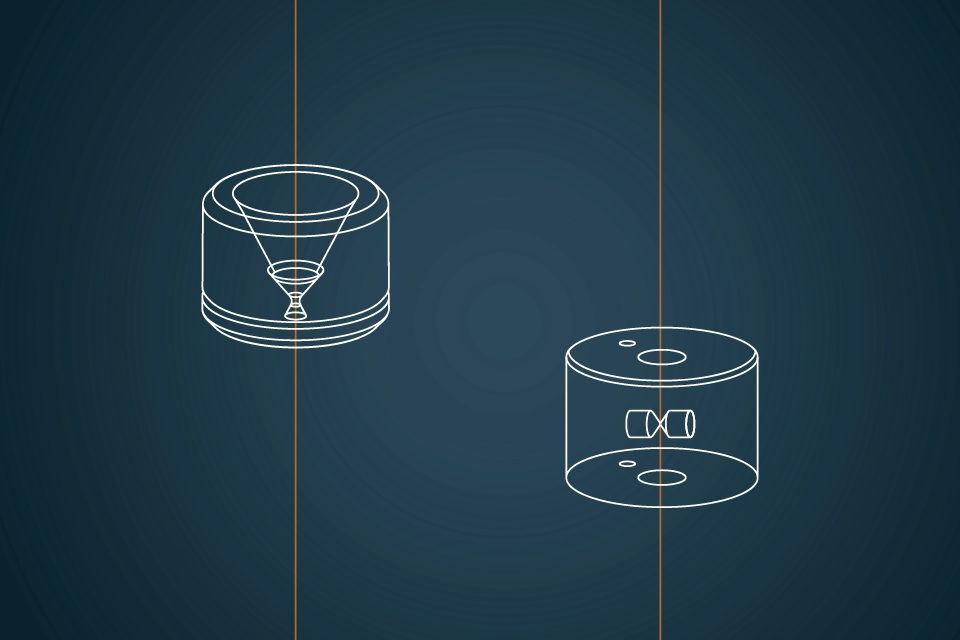

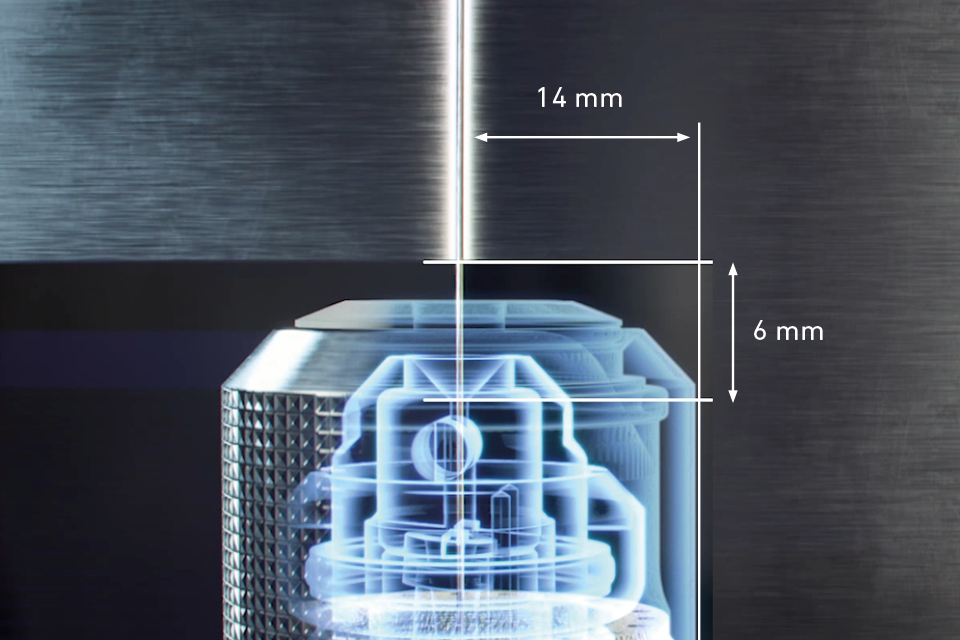

極致精準

減小導軌到工件的距離,提高了電極線的穩定性。

巧妙的熱補償裝置

人工智能的溫度管理

演算法和感應器可預測和減少熱影響,並補償軸變形

超高位置精度

在環境溫度變化高達 +/- 2.5 °C 時,定位精度為 +/- 1 um

請接受所有 cookies 以檢視外部內容。

雙線系統:自動換線系統 (AWC)

請接受所有 cookies 以檢視外部內容。

AWT:自動穿線

請接受所有 cookies 以檢視外部內容。

燒線系統

AWT的燒線裝置其流程是,將介於制動器與下機頭之間的電極線通電加熱,並將其線材拉伸、拉細至一段特定的長度後透過空壓噴流進行冷卻。而這樣的燒線整直流程,可產生出無毛邊的錐形線頭,在穿線的過程中可以更容易地穿過眼膜與工件。

優勢

- 即使在最困難的條件下,也能確保再穿線工作無誤

- 當在無人化的加工製程中,可連續性的加工模塊和開放式的內孔。

- 順暢平穩的自動化

請接受所有 cookies 以檢視外部內容。

UNIQUA HMI人機介面

請接受所有 cookies 以檢視外部內容。

UNIQUA是GF用於線切割機的全新人機介面 (HMI)。它代表了超世紀的放電加工技術的巔峰,也完美合併了我們之前所有人機介面 (HMI) 的最佳功能性和使用性(人體工程學)。

技術人員要求

UNIQUA對線切割資深專業技術人員和初學者而言都是一樣的。專業技術人使用時

強大的功能,使初學者也能簡單使用

而且學習曲線短

UNIQUA 的每種方法

都能按照您想要的方式工作。使用更新基本程式碼的功能將詳細的ISO程式碼或以物件導向格式的進行程式編輯,進而提升編輯程式的靈活性。

每位使用者

離線或在機器上工作。UNIQUA 可確保與主要 CAD/CAM 程式的相容性,還能提供具有整合 CAM 的強大圖形工具。

X 技術

X 技術是一套針對 CUT X 設計進行完美優化的切割技術,它集結了有史以來最好的線切割機台的所有價值。

極致精準

得益於 CUT X 從眼膜到工件的最小距離,以及噴流渠道的革命性設計,X 技術獲得超高輪廓精度。

簡單

操作員無需在精度、表面品質或速度之間做出妥協。X 技術是透過獨特的技術,在所有 3 個特色中達到最佳效果。就是這麼簡單。

操作員只需在 UNIQUA HMI 中選擇線材、工件材料、高度、眼膜系統(開放式或封閉式)和單線或雙線使用。X 技術就可以完成其餘任務。

快速

X 技術也是最快的技術,確保了 CUT X 機器的極高生產率和較短回報週期。而且,快速還意味著具有成本效益的可持續性,因為線材消耗被降到最低。

規格

CUT X 350

| Machine | |

| Type of machining | Submerged wire cutting |

| Dimensions of complete equipment * | 2520 x 2340 x 2154 mm 99.21 x 92.12 x 84.8 in |

| Total weight of the equipment without dielectric | 3900 kg 8598 lbs |

| Machining Area | |

| Work tank | Automatic drop tank |

| Accessibility | Front + Left sides |

| Max. workpiece dimensions * | 800 x 550 x 250 mm 31.49 x 21.65 x 9.84 in |

| Max. workpiece weight without bath | 450 kg 992 lbs |

| Dimensions of table ** | 680 x 450 mm 26.77 x 17.71 in |

| Floor-to-table distance | 1000-1100 mm 39.37-43.3 in |

| Total volume of dielectric fluid | 700 l 185 gal |

| Dielectric level adjustment | 0 – 250 mm (automatic) 0 – 9.84 in (automatic) |

| Dielectric type | Deionized water |

| X, Y, Z and U, V axes | |

| X, Y, Z travel * | 350 x 250 x 256 mm 13.78 x 9.84 x 10.08 in |

| U, V travel ** | ± 70 mm 2.75 in |

| Max. speed (X, Y and U, V axes) | 3 m/min 9.84 ft/min |

| Max. manual position speed | 2 m/min 6.56 ft/min |

| Linear glass scales | Standard on 4 axes (X,Y,U,V) |

| Integrated Collision Protection (ICP) | Standard on 5 axes (X,Y,Z,U,V) |

| Taper machining | |

| Max. taper | 30°/100 mm 3.94 in |

| Electrical supply (machine) | |

| Three-phase input voltage | 400 V ±10% |

| Maximum consumption | 10.4 kVA |

| Compressed air connection | |

| Pressure | 0.6 – 0.8 Mpa 87-116 PSI |

| Maximum consumption | 150 l/min 40 gal/min |

* Width x depth x height ** Width x depth

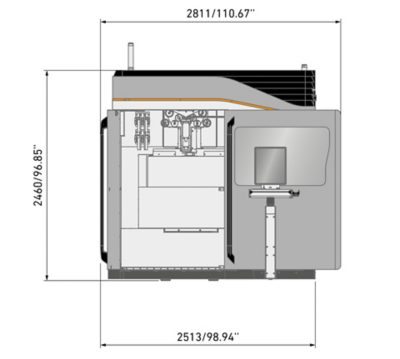

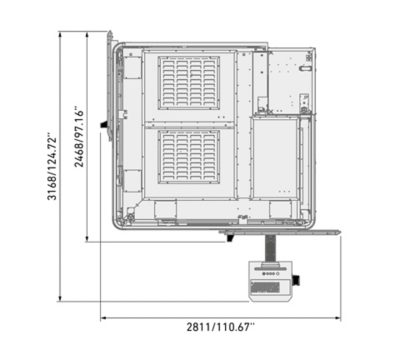

技術製圖

CUT X 500

| Machine | |

| Type of machining | Submerged wire cutting |

| Dimensions of complete equipment * | 2822 x 3533 x 2444 mm 111.1 x 139.09 x 96.22 in |

| Total weight of the equipment without dielectric | 4700 kg 10362 lbs |

| Machining Area | |

| Work tank | Automatic drop tank |

| Accessibility | Front + Left sides |

| Max. workpiece dimensions * | 1050 x 700 x 250 mm 41.34 x 27.56 x 9.84 in |

| Max. workpiece weight without bath | 800 kg 1764 lbs |

| Dimensions of table ** | 850 x 450 mm 33.46 x 17.71 in |

| Floor-to-table distance | 1000-1100 mm 39.37-43.3 in |

| Total volume of dielectric fluid | 950 l 251 gal |

| Dielectric level adjustment | 0 – 250 mm (automatic) 0 – 9.84 in (automatic) |

| Dielectric type | Deionized water |

| X, Y, Z and U, V axes | |

| X, Y, Z travel * | 500 x 350 x 256 mm 19.68 x 13.78 x 10.08 in |

| U, V travel ** | ± 70 mm 2.75 in |

| Max. speed (X, Y and U, V axes) | 3 m/min 9.84 ft/min |

| Max. manual position speed | 2 m/min 6.56 ft/min |

| Linear glass scales | Standard all axes (X,Y,U,V) |

| Integrated Collision Protection (ICP) | Standard on 5 axes (X,Y,Z,U,V) |

| Taper machining | |

| Max. taper | 30°/100 mm 3.94 in |

| Electrical supply (machine) | |

| Three-phase input voltage | 400 V ±10% |

| Maximum consumption | 10.4 kVA |

| Compressed air connection | |

| Pressure | 0.6 – 0.8 Mpa 87-116 PSI |

| Maximum consumption | 150 l/min 40 gal/min |

* Width x depth x height ** Width x depth

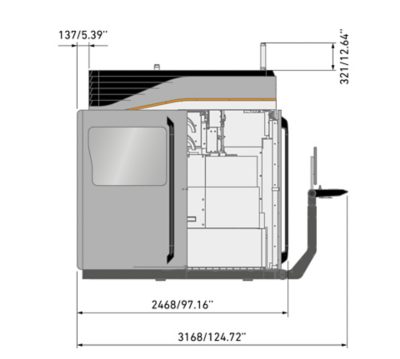

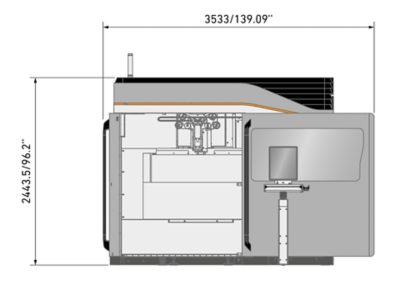

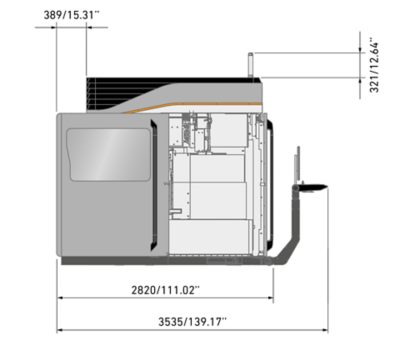

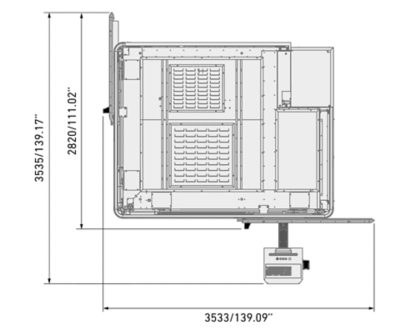

技術製圖

影片和型錄

CUT X 系列影片

請接受所有 cookies 以觀看 YouTube 影片。

提供最新資訊

請接受所有 cookies 以檢視外部內容。