Please accept all cookies to view the external content.

MILL X 400 – MILL S 500/600/800

Please accept all cookies to view the external content.

MILL X 400

MILL X 400

MILL S 500

MILL S 500

MILL S 600

MILL S 600

MILL S 800

MILL S 800

- MILL X 400

- MILL S 500

- MILL S 600

- MILL S 800

Applications

Jig grinding

Secure and reduce your manufacturing process for optimal surface quality with a single machine

Please accept all cookies to view the external content.

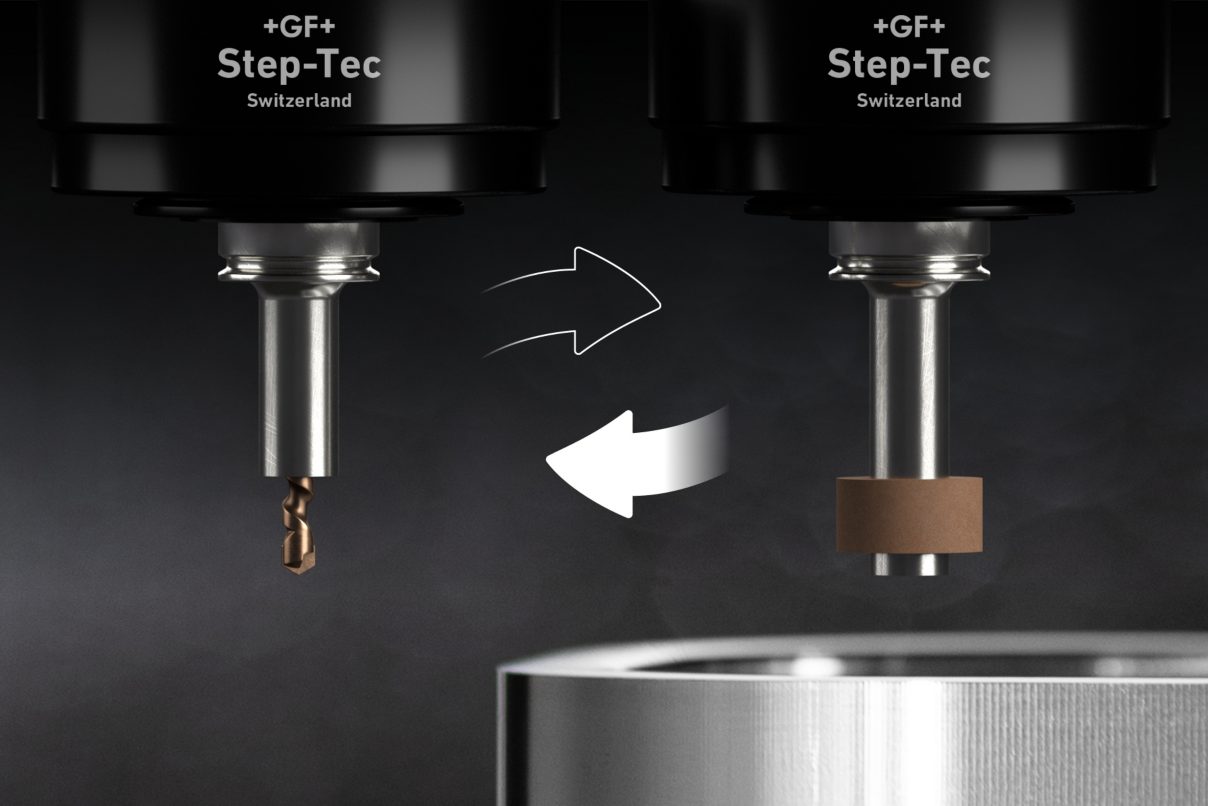

Mikron MILL S/X machines are able to combine Milling and jig grinding on the same machine. The grinding setup into the machine has been well designed in order to maintain standard workpiece dimensions and clamping surface even for Automation. Nevertheless, the laser measuring system and the dressing spindle are located closer to the working area for a quick and fast grinding process. Through this two-in-one solution, GF Machining Solutions improves and significantly reduces customers’ manufacturing processes. The combination of milling and grinding technologies, extremely high machine dynamics, and consistent thermal stability and accuracy provide fast ROI and high-end, quality products.

Please accept all cookies to view the external content.

Two-in-one solution

Combine Milling and jig grinding on a single machine to both reduce the part manufacturing process and increase surface quality. The closed grinding process (grinding + measuring) accelerates your time to market.

Monitor your process

Dressing spindle is equipped with an acoustic emission (AE) sensor to track and visualize on the Heidenhain control the signal during tool dressing. The machine can be equipped with an additional AE sensor to track grinding operations in order to further optimize the process.

Sustainability

Maintaining the highest level of precision while consuming less energy, the Mikron MILL S/X series is a sustainable solution for any high-end milling challenges. This starts with design of the machine from the very beginning, with a new control unit, a more efficient exhaust system and intelligent temperature control.

Please accept all cookies to view the external content.

Specifications

MILL X 400

| Main specifications | |

| Travel X,Y,Z |

500 x 450 x 360 mm 19.68 x 17.72 x 14.17 in |

| Rapid traverse X,Y,Z | 100 m/min 3,937 in/min |

| Working spindle (40% ED, S6) | 30,000 (HSK-E40) / 13.5 / 8.8 rpm/kW/Nm 42,000 (HSK-E40) / 13.5 / 8.8 rpm/kW/Nm |

| Pallet/clamping surface | Dynafix 280 x 280/350 x 350 UPC 320 x 320 |

| Max. load (incl. pallet) | 120 kg 264 lbs |

| Tool magazine | 18/36/68/168 (HSK-E40) |

| Machine weight | 6,800 kg 14,991 lbs |

| Control unit | TNC 640 (Heidenhain) |

Technical drawings

MILL S 500

| Main specifications | |

| Travel X,Y,Z |

500 x 450 x 360 mm 19.68 x 17.72 x 14.17 in |

| Rapid traverse X,Y,Z | 61 m/min 2,401 in/min |

| Working spindle (40% ED, S6) | 30,000 (HSK-E40) / 13.5 / 8.8 rpm/kW/Nm 42,000 (HSK-E40) / 13.5 / 8.8 rpm/kW/Nm |

| Work table | 590 x 450 mm 23.23 x 17.72 in |

| Max. load (incl. pallet) | 200 kg 441 lbs |

| Tool magazine | 18/36/68/168 (HSK-E40) |

| Machine weight | 6,800 kg 14,991 lbs |

| Control unit | TNC 640 (Heidenhain) |

Technical drawings

MILL S 600

| Main specifications | |

| Travel X,Y,Z |

600 x 600 x 500 mm 23.62 x 23.62 x 19.68 in |

| Rapid traverse X,Y,Z | 61 m/min 2,401 in/min |

| Working spindle (40% ED, S6) | 42,000 (HSK-E40) / 13.5 / 8.8 rpm/kW/Nm 36,000 (HSK-E50) / 33 / 21 rpm/kW/Nm |

| Work table | 900 x 600 mm 35.43 x 23.62 in |

| Pallet/clamping surface | 800 x 600 mm 31.5 x 23.62 in |

| Max. load (incl. pallet) | 500 kg 1102 lbs |

| Tool magazine | 18/36/68/168 (HSK-E40) 15/30/60/120/170/220 (HSK-E50) |

| Machine weight | 9,900 kg 21,825 lbs |

| Control unit | TNC 640 (Heidenhain) |

Technical drawings

MILL S 800

| Main specifications | |

| Travel X,Y,Z |

800 x 600 x 500 mm 31.5 x 23.62 x 19.68 in |

| Rapid traverse X,Y,Z | 61 m/min 2,401 in/min |

| Working spindle (40% ED, S6) | 42,000 (HSK-E40) / 13.5 / 8.8 rpm/kW/Nm 36,000 (HSK-E50) / 33 / 21 rpm/kW/Nm |

| Work table | 900 x 600 mm 35.43 x 23.62 in |

| Pallet/clamping surface | 800 x 600 mm 31.5 x 23.62 in |

| Max. load (incl. pallet) | 1000 kg 2204 lbs |

| Tool magazine | 18/36/68/168 (HSK-E40) 15/30/60/120/170/220 (HSK-E50) |

| Machine weight | 9,900 kg 21,825 lbs |

| Control unit | TNC 640 (Heidenhain) |

Technical drawings

Discover our videos

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Testimonials

Testimonial video - Leuthold Mechanik AG

Testimonial Leuthold Mechanik AG – About the MILL X 400 G

Please accept all cookies to view the youtube video content.