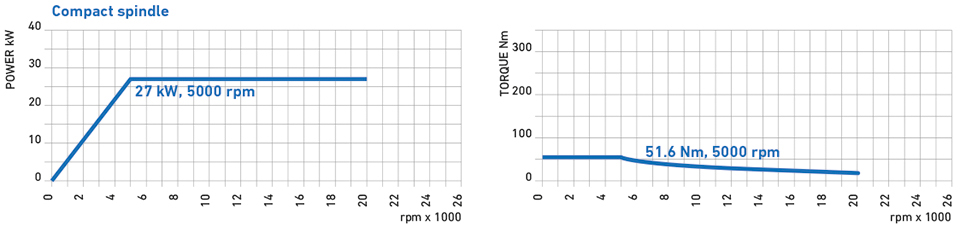

Step-Tec HPC 240 - One Touch

Dimensions / weight

ø240 x 694 mm / 152 kg

| Dimensions / weight | ø240 x 694 mm / 152 kg |

| Speed (nmax) | 18’000 rpm |

| Torque S1 / S6 40% | 159 / 202 Nm |

| Power S1 / S6 40% | 30 / 38 kW |

| Interfaces | SK 40, SK 50. HSK A/C/T 63, HSK A/T 80, HSK A/T 100 |

| Through Spindle Coolant | O, H2O, oil, Co2, MQL |

| Lubrification | oil-air / grease |

| Cooling | OptiCool, Option: CoolCore (Shaft cooling) |

| Sensors | Encoder, Tool Position Monitoring, Temperature, Vibration, axial expansion (option) |

| Mill-Turn function | Interlock (SSL) 500 Nm |

| Software (options) | Spindle Diagnostic Software, Spindle Monitoring Software |

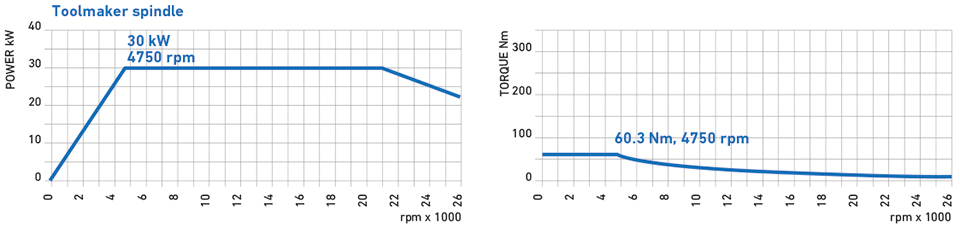

Step-Tec HPC 240 - Tool Maker

Dimensions / weight

ø240 x 694 mm / 150 kg

| Dimensions / weight | ø240 x 694 mm / 150 kg |

| Speed (nmax) | 26’000 rpm |

| Torque S1 / S6 40% | 60.3 / 76.4 Nm |

| Power S1 / S6 40% | 30 / 38 kW |

| Interfaces | HSK A/C 63, HSK F 80 |

| Through Spindle Coolant | O, H2O, oil, Co2, MQL |

| Lubrification | oil-air |

| Cooling | OptiCool, Option: CoolCore (Shaft cooling) |

| Sensors | Encoder, Tool Position Monitoring, Temperature, Vibration, axial expansion (option) |

| Software (options) | Spindle Diagnostic Software, Spindle Monitoring Software |

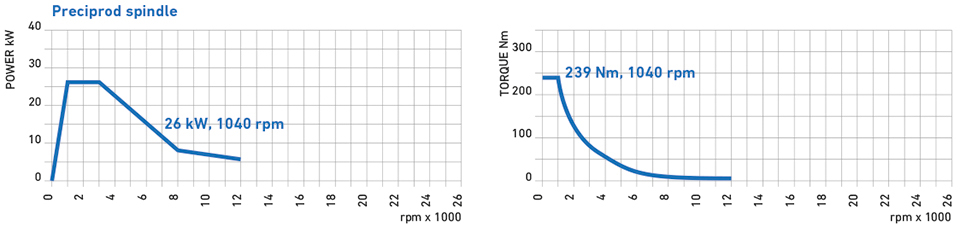

Step-Tec HPC 240 - Preciprod

Dimensions / weight

ø240 x 694 mm / 152 kg

| Dimensions / weight | ø240 x 694 mm / 152 kg |

| Speed (nmax) | 12’000 rpm |

| Torque S1 / S6 40% | 239 / 302 Nm |

| Power S1 / S6 40% | 30 / 38 kW |

| Interfaces | SK 50. HSK A/C/T 63, HSK A/T 80, HSK A/T 100 |

| Through Spindle Coolant | O, H2O, oil, Co2, MQL |

| Lubrification | oil-air / grease |

| Cooling | OptiCool, Option: CoolCore (Shaft cooling) |

| Sensors | Encoder, Tool Position Monitoring, Temperature, Vibration, axial expansion (option) |

| Mill-Turn function | Interlock (SSL) 500/800 Nm |

| Software (options) | Spindle Diagnostic Software, Spindle Monitoring Software |