What is Laser Micromachining?

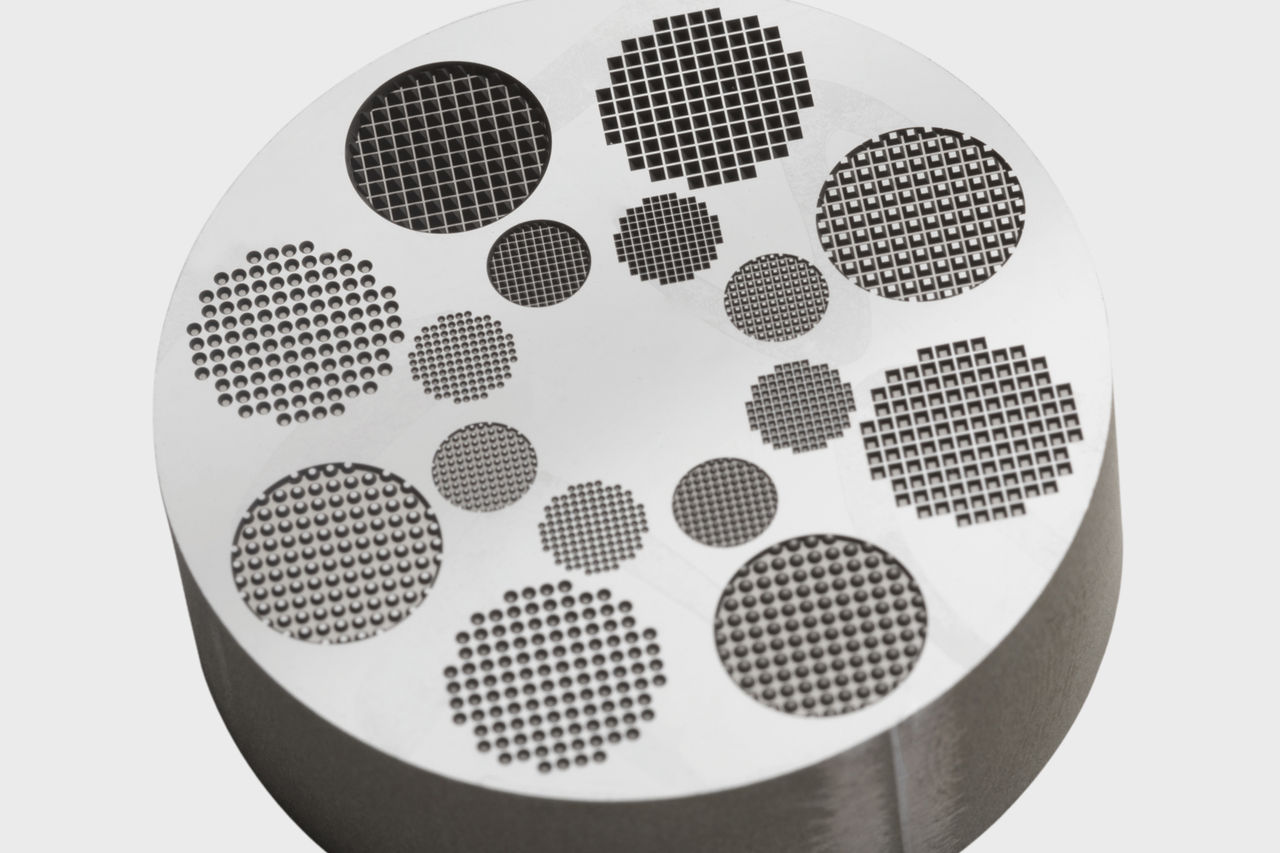

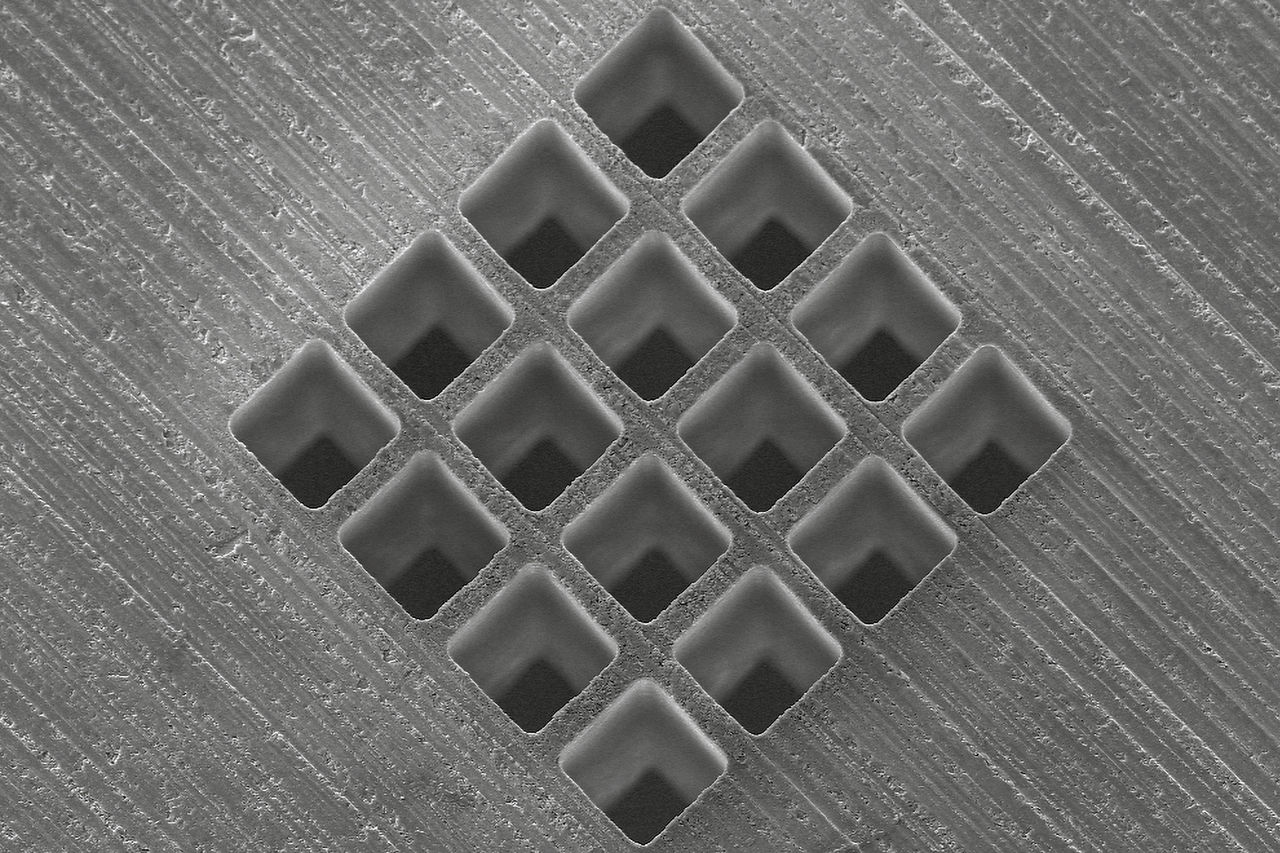

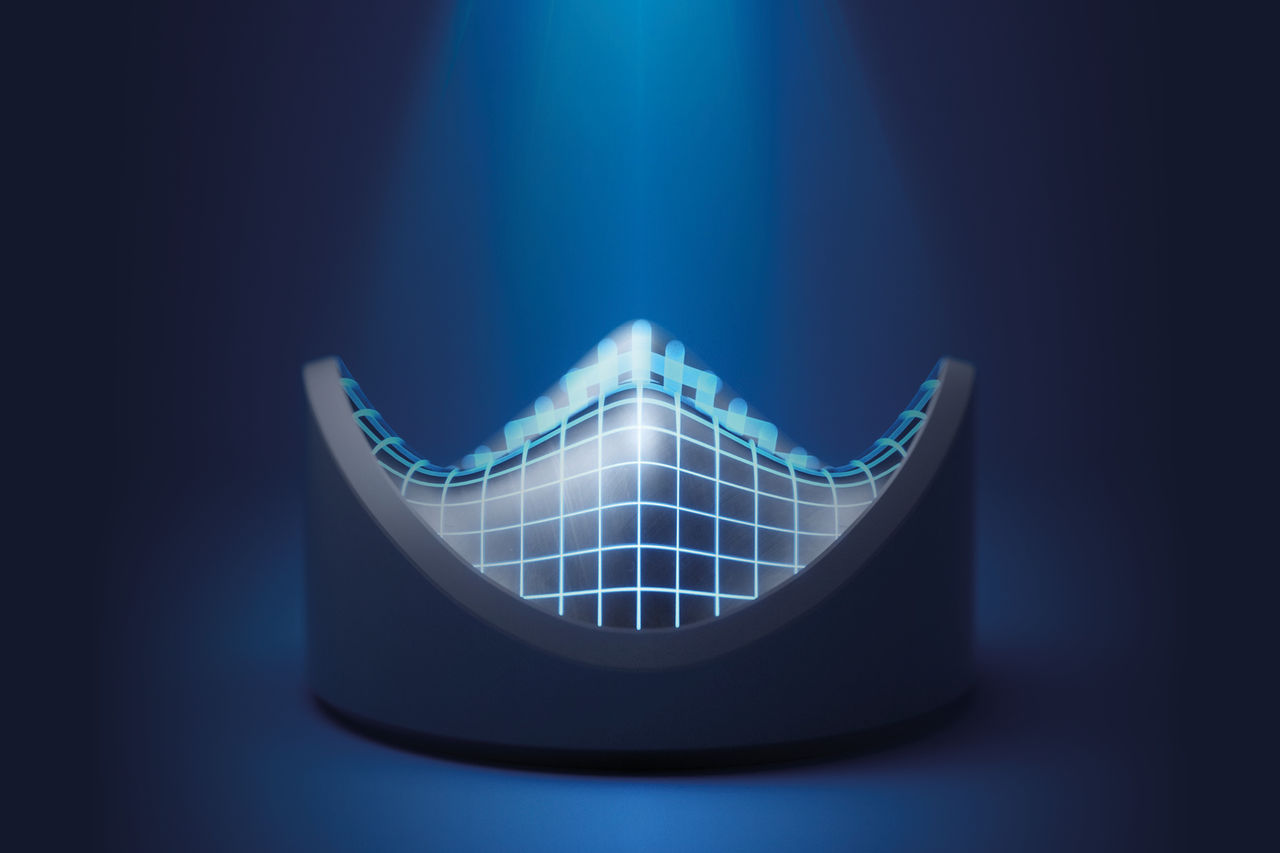

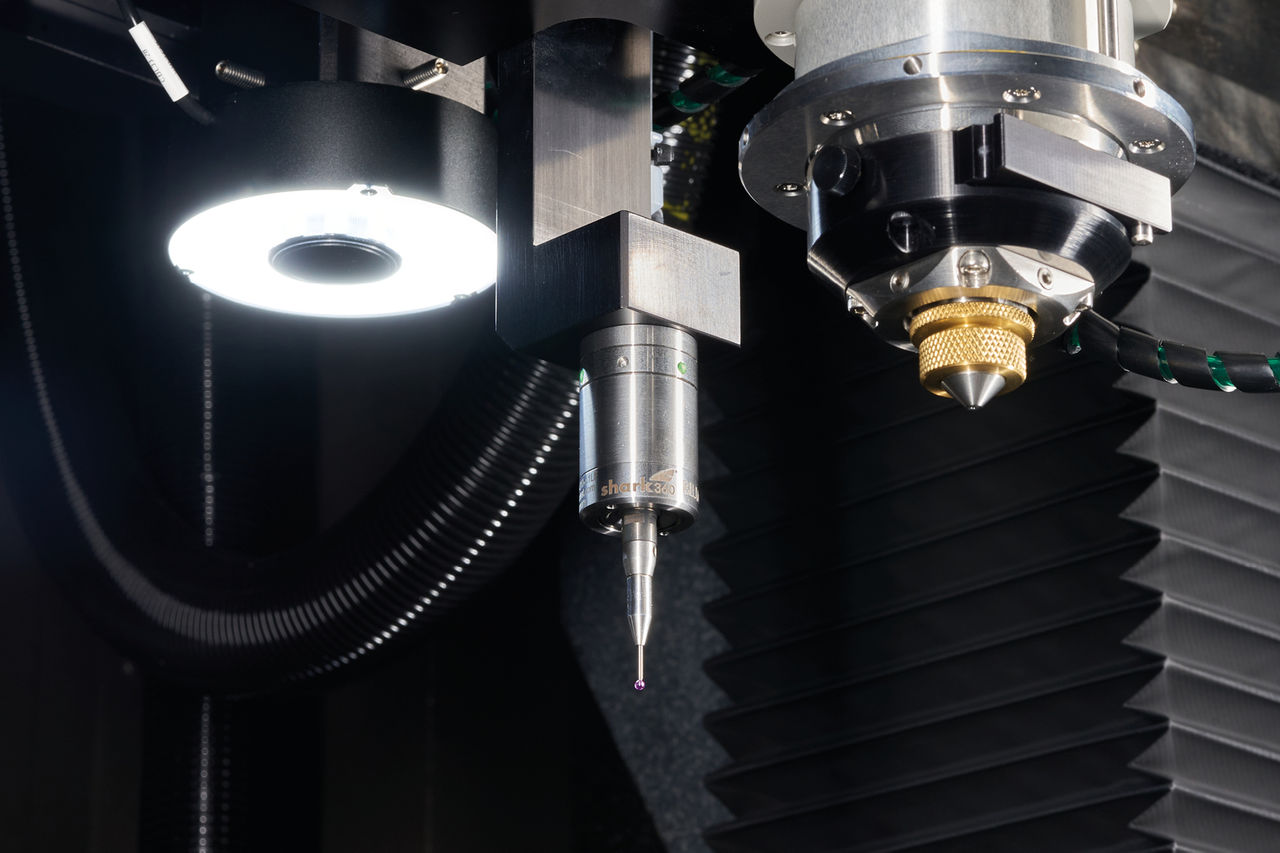

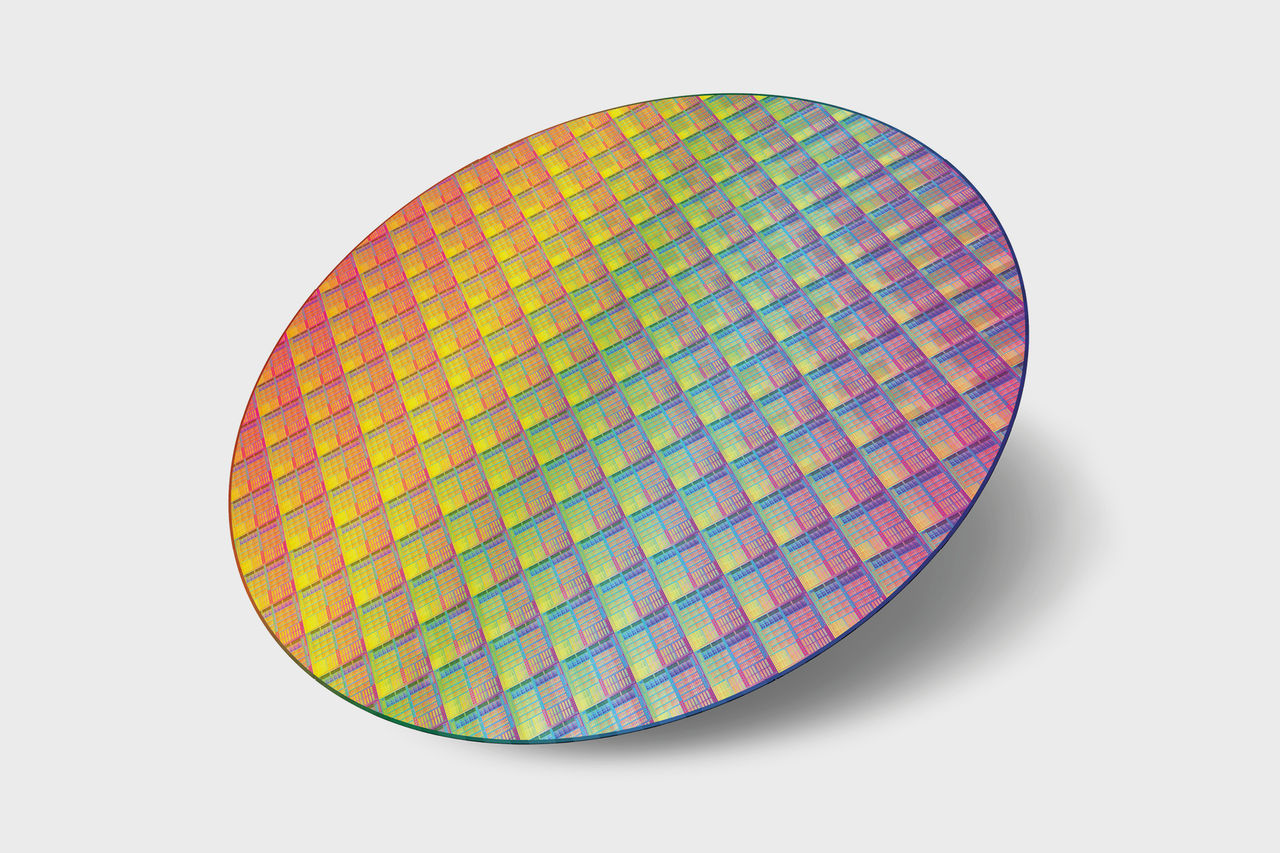

Laser Micromachining is a precision manufacturing process that uses a laser beam to remove material at a microscopic scale. Machined parts can be relatively large whereas the structures produced, such as holes, grooves or shapes, may range between a few microns and a few millimeters. Depending on the optical setup, the size of the Laser tool is typically between 10 and 60 µm, which allows for processing of fine features in any kind of material, including very hard and brittle material.

Why come to CHARMILLES for Laser Micromachining?

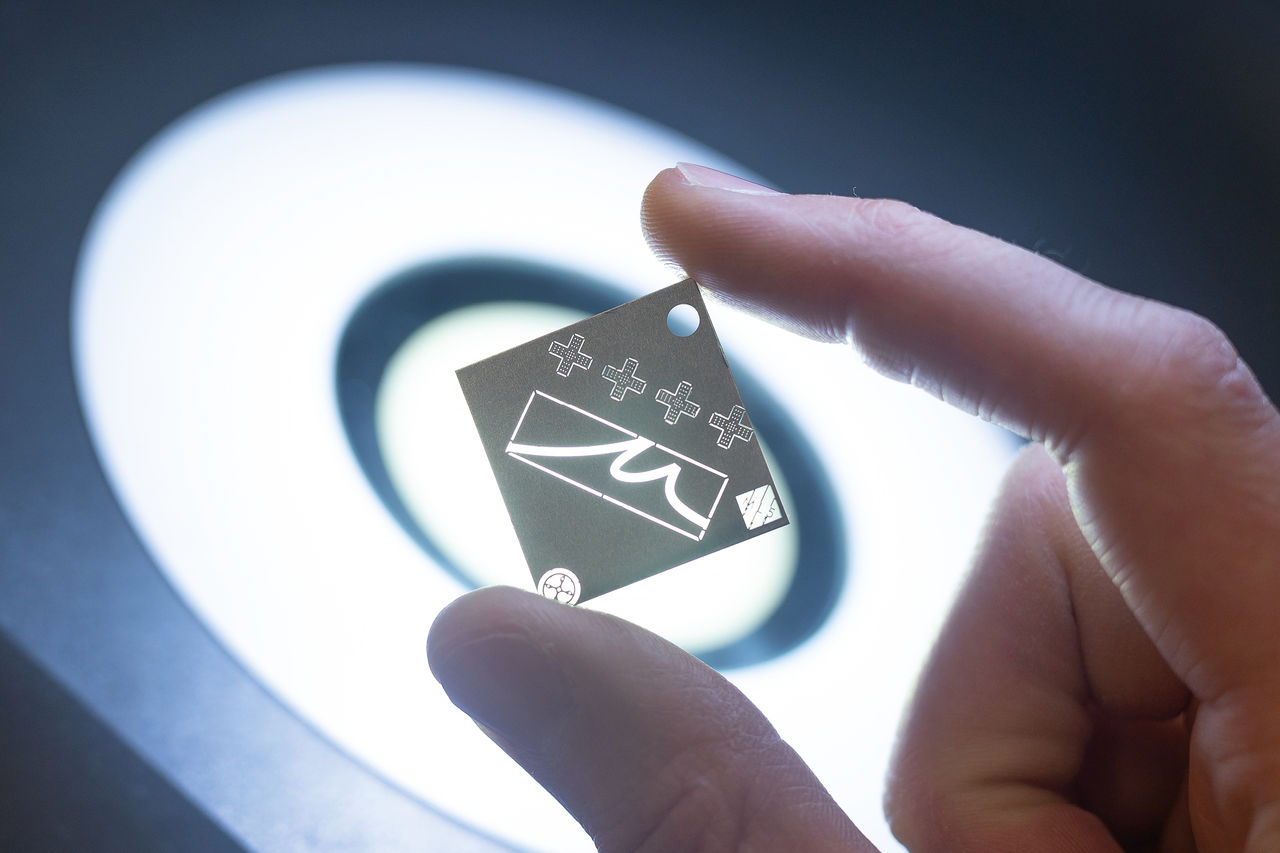

With a strong expertise in software development and photonics, CHARMILLES continuously develops Laser systems inspired by 70 years of experience in state-of-the-art precision machining centers.

With the integration of Microlution in 2016, CHARMILLES has significantly reinforced its position in Laser Micromachining and is now an innovation and market leader.

Please accept all cookies to view the youtube video content.

Most micromachining applications require ultra-short pulsed lasers, also called femto lasers. Building on 15 years of experience with femto lasers, CHARMILLES develops its own products - such as the Femto FlexiPulse™ - with the best Laser Manufacturers in the world.

Thanks to a global presence and unique know-how, CHARMILLES Laser application engineers and the UNITED MACHINING Academy are here to support you and help you realize the full potential of your application with a CHARMILLES Laser machine.

Main competitive advantages

Overview of the series

Please accept all cookies to view the external content.

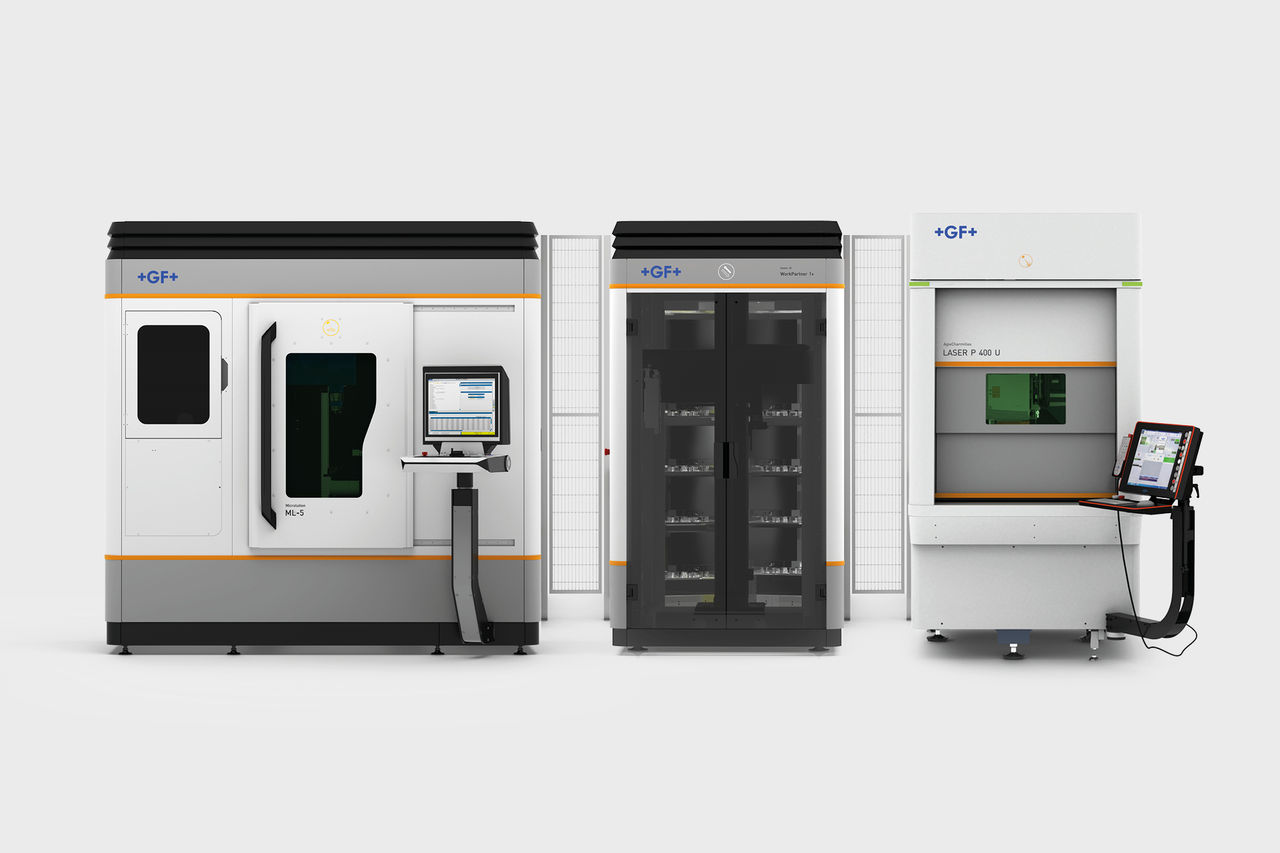

Our range of Laser micromachining machines

Please accept all cookies to view the external content.

CHARMILLES LASER P and S

A/B or B/C travel

Laser sources

| Machine | XYZ (mm) A/B or B/C travel Laser sources |

| LASER P 400 | 600 x 400 x 300 - Femto / Nano / Femto + Nano |

| LASER P 400 U | 600 x 400 x 300 +115-105°/720° Femto / Nano / Femto + Nano |

| LASER S 500 | 550 x 400 x 500 - Femto / Nano / Femto + Nano |

| LASER S 500 (U) |

550 x 400 x 500 B/C: -110/+110°; 0/720° Femto / Nano / Femto + Nano |

| LASER S 1000 U | 1000 x 550 x 880 180°/720° Femto / Nano / Femto + Nano |

| LASER S 1200 U | 1200 x 900 x 970 180°/720° Femto / Nano / Femto + Nano |