GF Machining Solution helps you prepare for the technical, business and environmental challenges in the dynamic landscape of global packaging mold manufacturing. Discover our best-in-class solutions built on decades of customer satisfaction.

Discover our expertise in Packaging

Other key applications

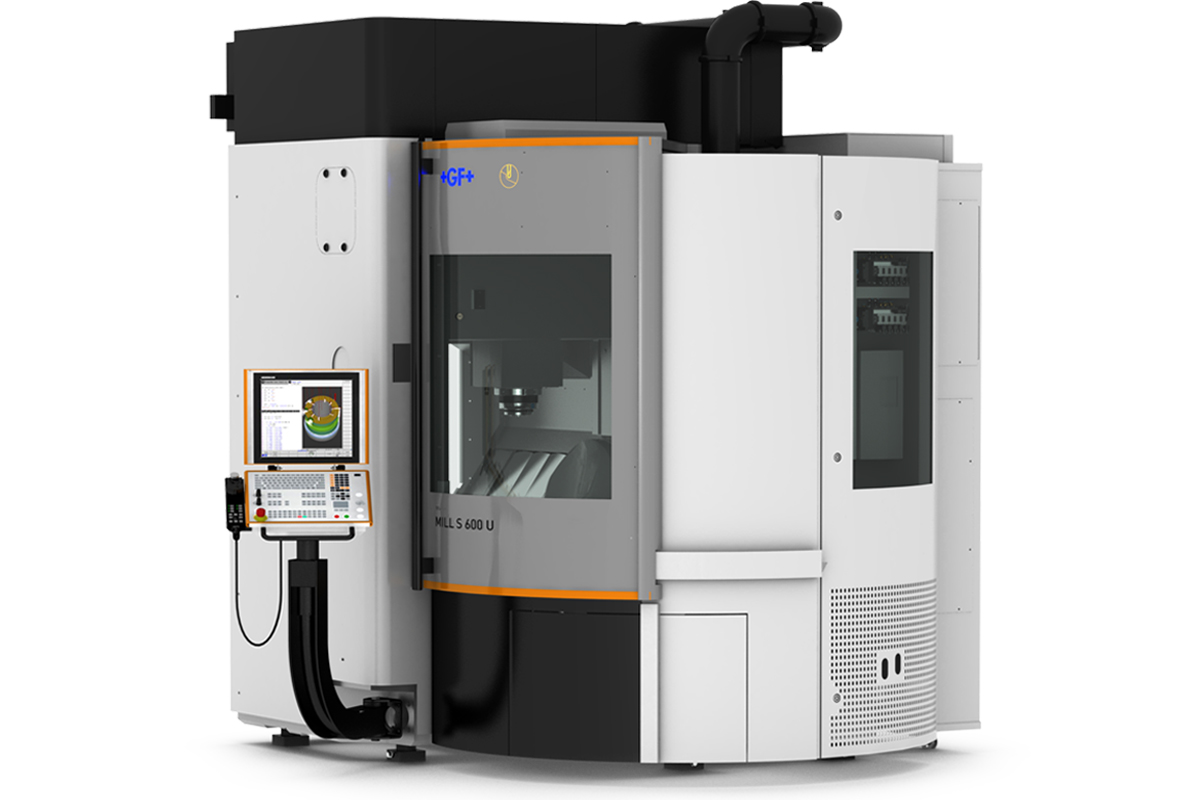

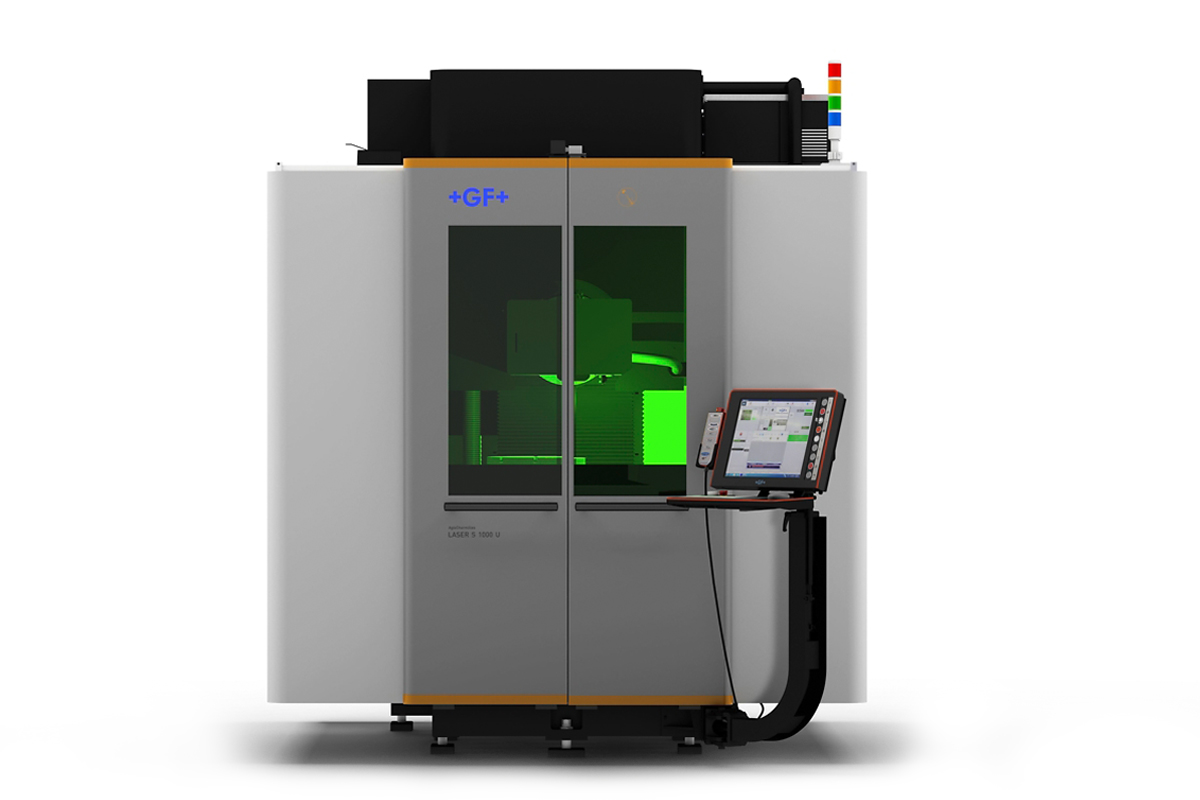

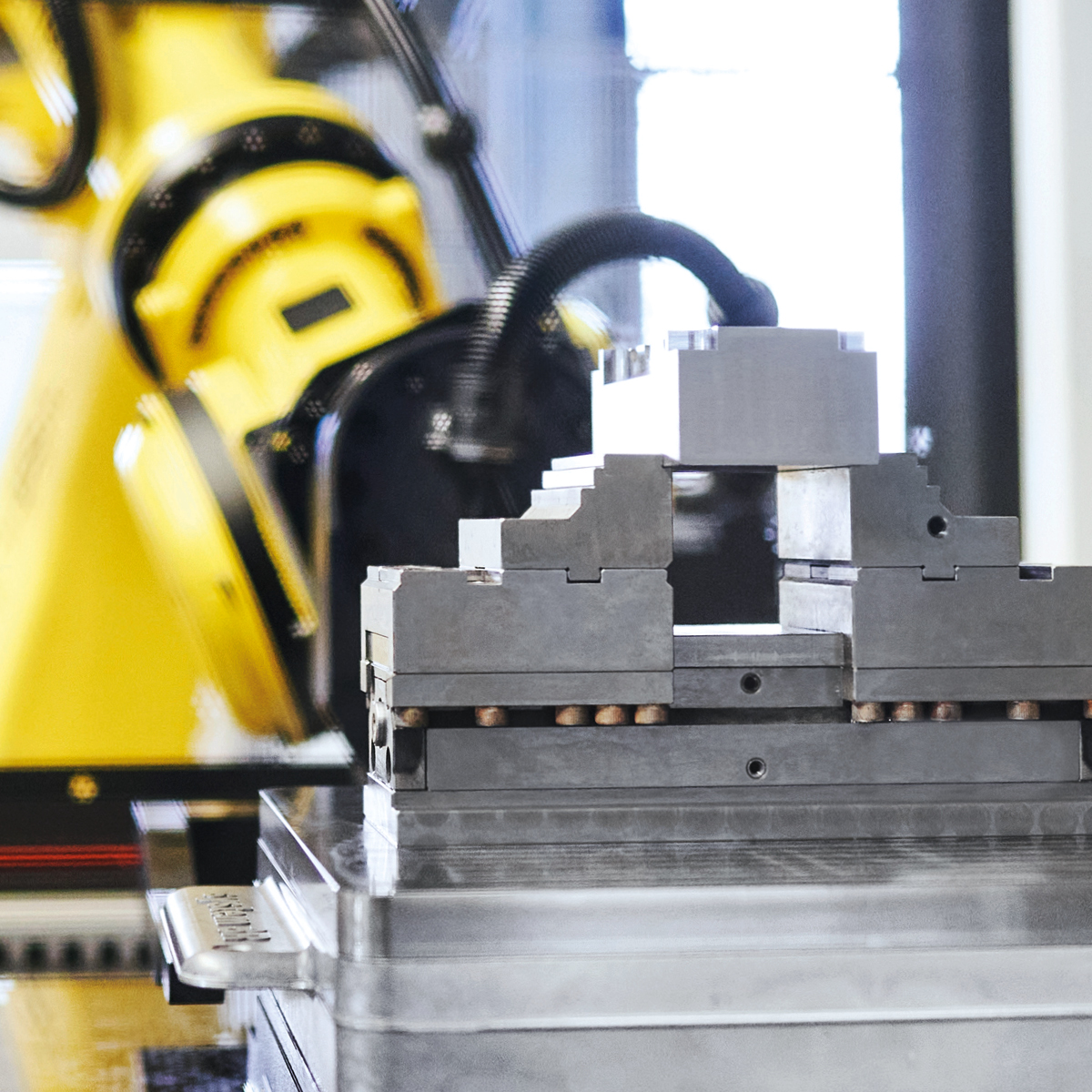

Our technologies

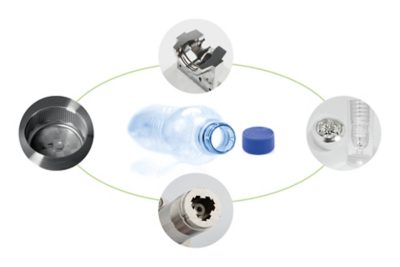

Complete mold manufacturing solution

Our solutions for blow molds, neck rings, caps and closures

Our solutions for blow molds, neck rings, caps and closures

Neck ring manufactured with Additive Manufacturing

Neck ring manufactured with Additive Manufacturing

Milling, cutting, eroding, grinding preform mold components

Milling, cutting, eroding, grinding preform mold components

Caps mold core structured with Laser and Die-sinking EDM for perfect injection

Caps mold core structured with Laser and Die-sinking EDM for perfect injection

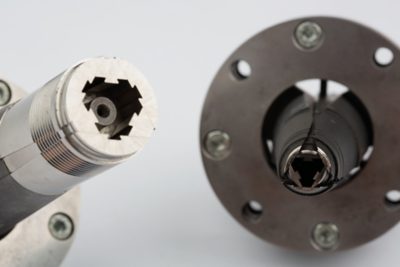

High-accuracy collapsible core manufactured with Wire-cutting EDM for seamless cap ejection

High-accuracy collapsible core manufactured with Wire-cutting EDM for seamless cap ejection

Blow mold with 5-axis Milling and Laser for mastered surface finish and functionalities

Blow mold with 5-axis Milling and Laser for mastered surface finish and functionalities

GF Machining Solutions' comprehensive offer to manufacture all the elements necessary for plastic-molded bottles

GF Machining Solutions' comprehensive offer to manufacture all the elements necessary for plastic-molded bottles

- Complete Mold manufacturing solution for PET Bottle Industry

- Neck ring with DMLS Additive Manufacturing for extended productivity

- Milling, cutting, eroding, grinding preform mold components

- Caps mold core structured with Laser and DS EDM for perfect injection

- Wire EDM manufactures high accuracy collapsible core for seamless caps ejection

- Blow mold with 5 axis Milling & Laser for mastered surface finish and functionality

- Bottle molds

1/

Discover our Packaging videos

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.