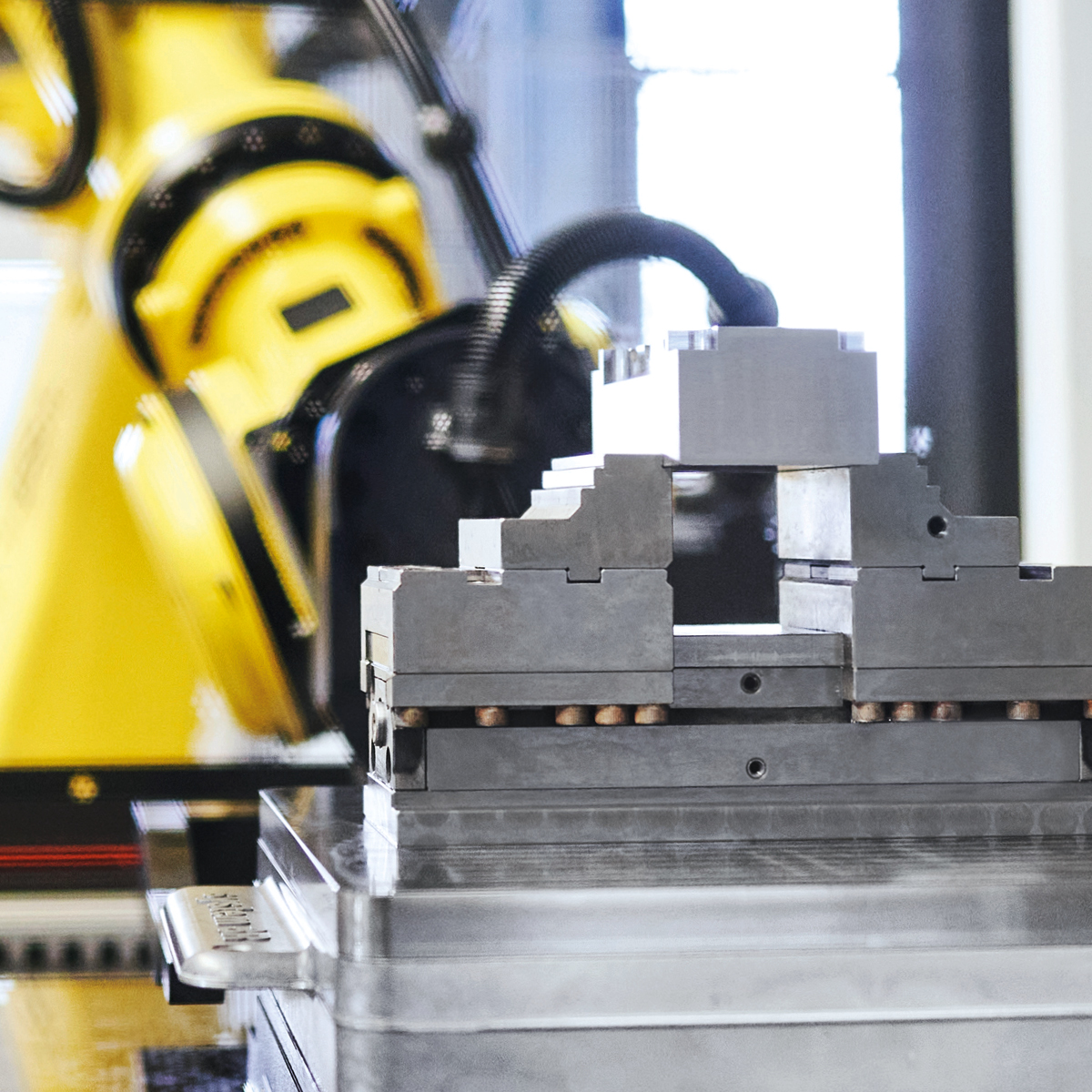

Deep cavity machining with 5-axis Milling

Increased consumer demands and product design puts pressure on mold makers to produce molds faster. With our 5-axis high-speed Milling solution, mold makers can achieve:

- High material removal rates

- Shortened tools to achieve excellent surface finish and feature integrity with 5-axis operation

- Robust machine design to guarantee repeatability on cavity manufacturing

Cavity surface restructuring with Laser ablation

Our unique 5-axis Laser solution enables texturing of mold cavities to create aesthetic designs on packaging. The LASER S 1000 U brings you:

- Increased productivity and texture quality withSmartpatch

- Continuous texture without patch line on three-dimensional surfaces

- Ability to machine a variety of mold tool material for plastics, resins and biodegradable material

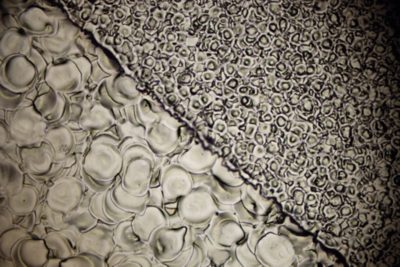

3DS demolding surface with Die-sinking EDM

Our Die-sinking EDM offers a unique solution to achieve controlled mold cavity surface structures, in order to ease demolding during injection processes:

Modulate mold surface to achieve effortless injection molding process

Achieve high quality with parametric controlled VDI, surface roughness and surface area

Boost productivity with a controlled injection process and reduced scrap rates