Micro connectors leads stamping tools

Our Die-sinking EDM machines with micro-machining capabilities, connector technology and ISPG (Intelligent Speed Power Generators) facilitate the increasing demand for micro connectors.

- Achieve low surface roughness (Ra 0.09 μm) for burr-free stamped connector leads

- Micromachine cavity size 0.03 mm

- Optimize the production chain by eliminating the need for multiple adjustments

- Precise machining with ISPG and advanced connector technology

Micro-punch for connector leads

Our Wire EDM technology enables you to create tooling for trimming, forming and cutting micro connector leads with intricate details. Our solution ensures long-term profitability and productivity:

- Achieve high accuracy features for microelectronics

- Implement fine wire cutting technology in a simplified and stable manner

- Achieve burr-free, sharp profiles to facilitate easy operation with AC Cut AH Ø 0.05 mm wire

- Guarantee long-term production accuracy with X-treme precision, calibration standards and Dynamic Corner Control (DCC)

Connector housing molds

Connector housings provide mechanical support and inertness from the environment. These housings contain reinforced ribs, slots for locking and slots for wiring leads. With our Die-sinking EDM and Milling solution:

- Execute an economic and accurate production of connector housing injection molds

- Fully automate your process to achieve high repeatability by integrating electrode Milling and Die-sinking EDM

- Take advantage of a thermally stable process to enhance part accuracy and long-term reliability

Electrode for connector housing molds

The electrodes to machine connector housing inserts require intricate geometrical details. With our electrode Milling solution, you can achieve:

- Greater geometrical details with high-speed machining and small cutters

- High surface finish with high-speed asynchronous spindles

- High accuracy on the contours

- Highly productive and clean environment thanks to the integrated dust evacuation system

Micro-electrode for connector lead tool

Our high-speed electrode machining solution enables manufacturing of accurate electrodes for micro-structuring connector tools:

- Achieve accurate shape profile

- Achieve high surface finish

- Use small cutters to machine micro features with high speed and thermal stability

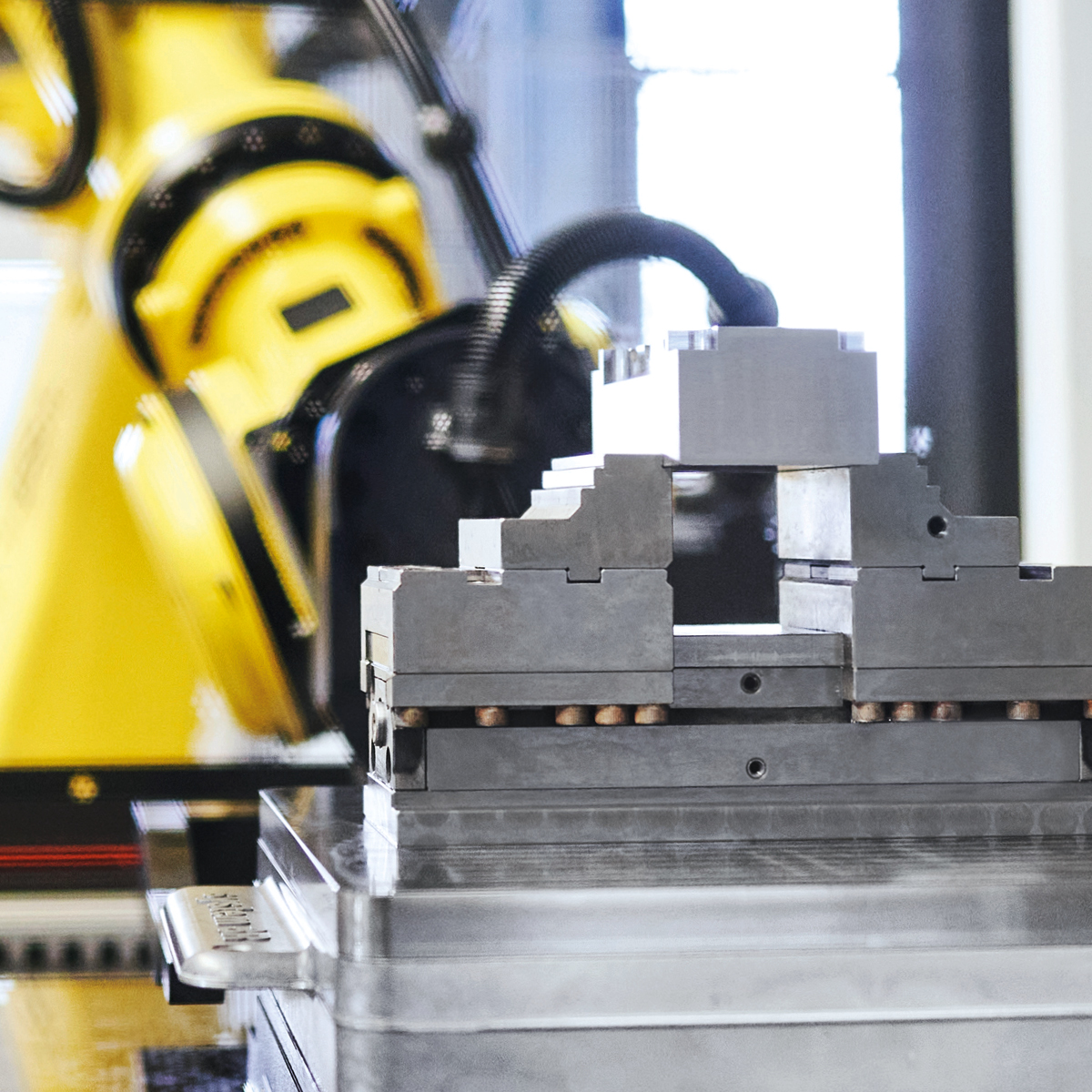

Connector die tool

Our Wire EDM solution allows manufacturing of progressive stamping tool elements for clean burr-free stamping of industrial connector leads:

- Automatic Twin Wire technology for 30% faster roughing & finish

- Achieve sharp edges and high surface finish with thin wire roughing Ø 0.25 mm finishing Ø 0.1 mm

- Guarantee long-term production accuracy with X-treme precision, calibration standards and Dynamic Corner Control (DCC)

Complete stamping tooling for connector leads

To match the market demand for connectors, progressive stamping technology is used with components manufactured from steel and carbide to allow the uninterrupted production of millions of connection leads. Our extensive Wire EDM products provide a complete solution for production of such tools while simultaneously delivering on quality, cost and productivity:

- <2 μm accuracy from CAD to complete tool

- Easy pairing of parts due to close machining tolerance

- Easy machining of steel and carbide

- Increased productivity with System 3R Tooling and part automation