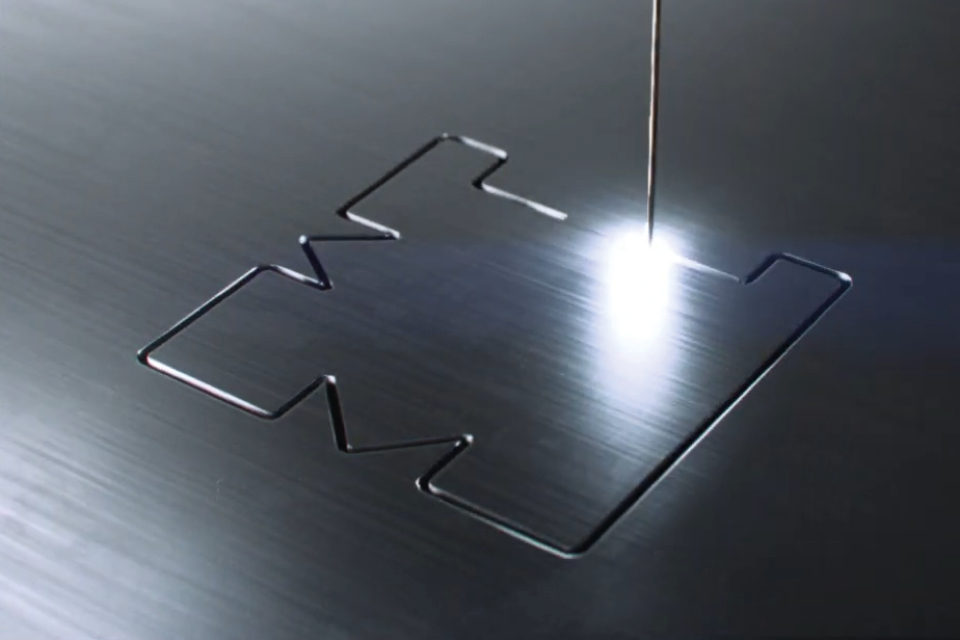

What is Wire-cutting EDM?

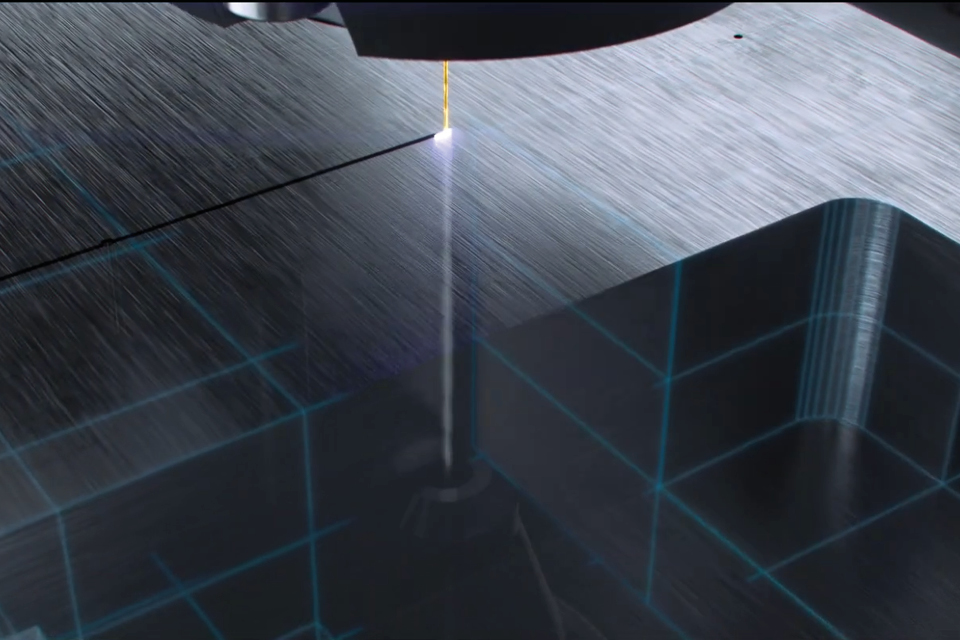

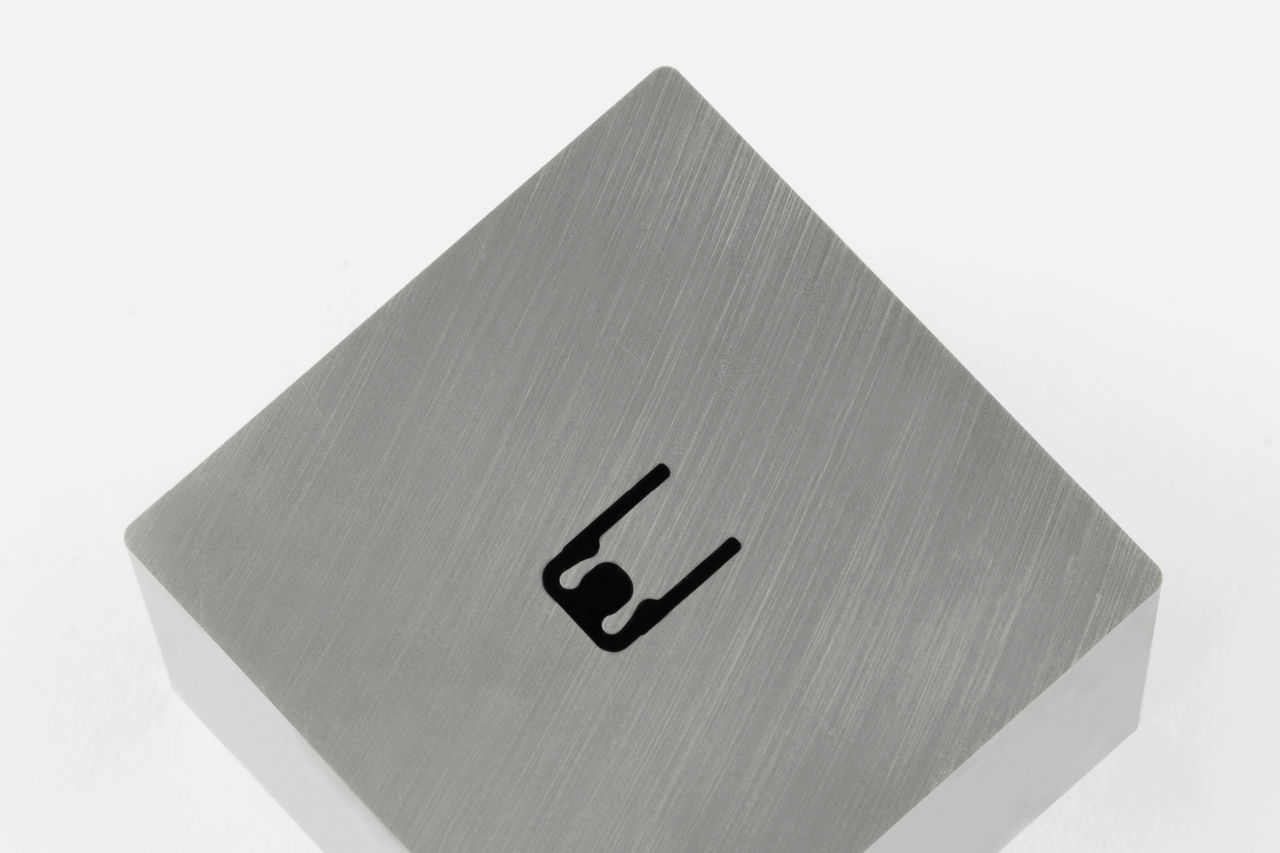

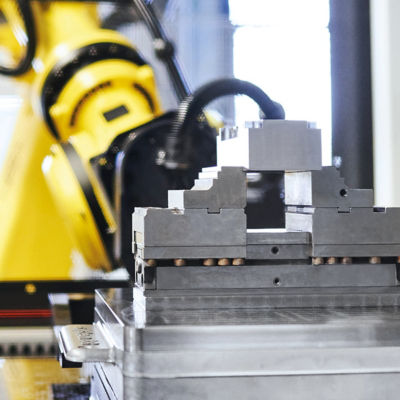

The Wire EDM process uses an electrical spark created between two conductive parts, a wire that cuts and a part from which material will be removed. Using a dielectric solution to control the electrical discharge and applying the metallic wire to cut a programmed contour, a Wire EDM machine can produce extrusion dies, blanking punches, precise molds, special parts with small features and many more.

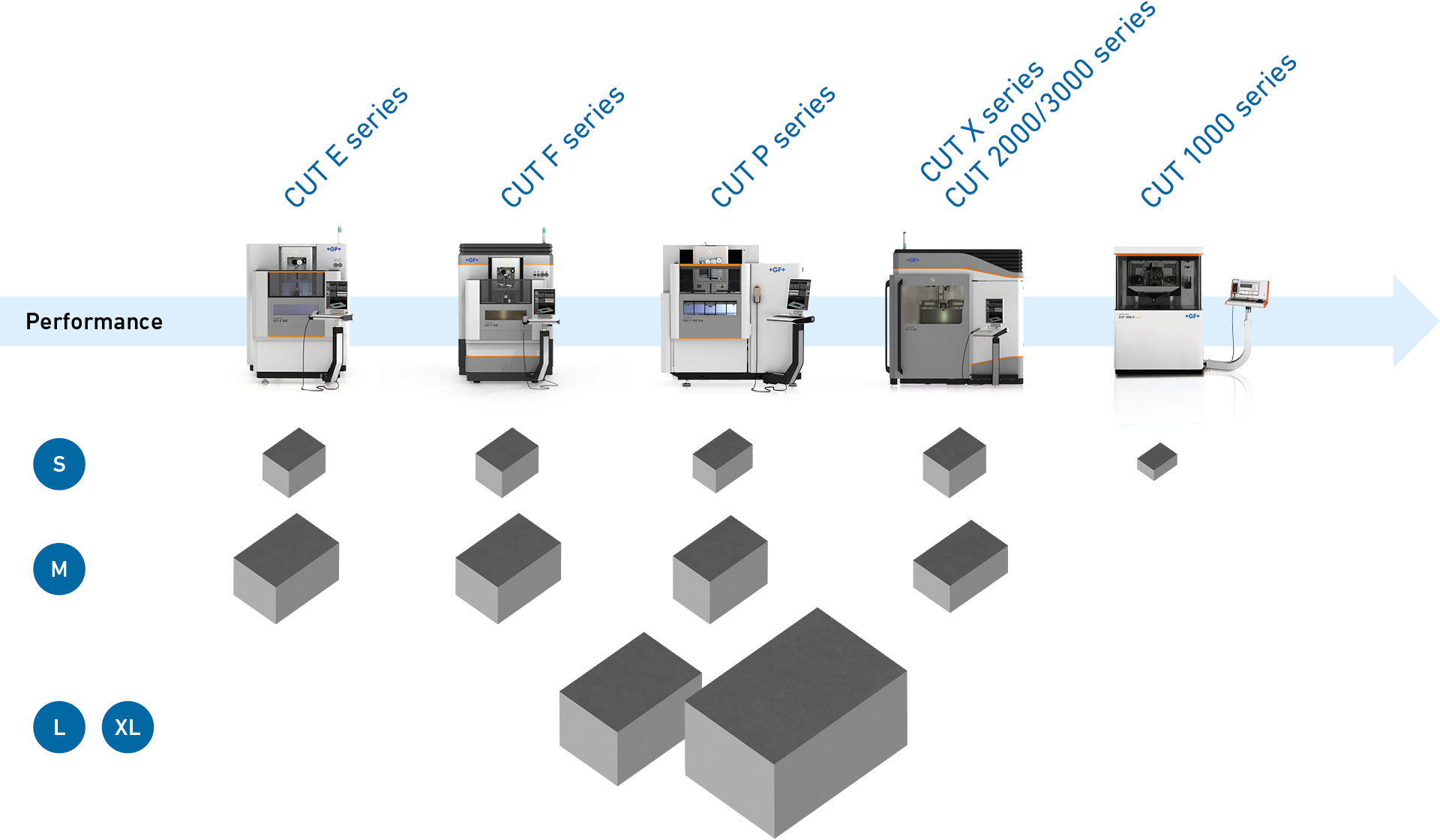

Why come to AGIE CHARMILLES for your wire cutting machine?

At the forefront of the EDM cutting industry for more than a hundred years, AGIE CHARMILLES has a proven record of providing reliable and high-performance solutions for wire electrical discharge machines. With a strong technical expertise and a solid patent history, AGIE CHARMILLES is your preferred partner for any wire EDM machining project, whether it be ultraprecise machining, mold making, or simply a process requiring high-precision cutting performances. Discover our unique innovations that allow our machines to provide outstanding performances.