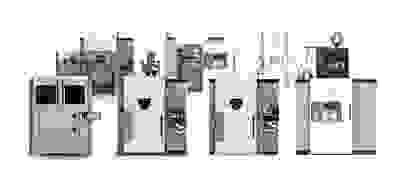

DMP Factory 500 Full Modules

DMP Factory 500 Full Modules

DMP Factory 500 Printer Front Closed

DMP Factory 500 Printer Front Closed

DMP Factory 500 Printer Side Closed

DMP Factory 500 Printer Side Closed

DMP Factory 500 Printer Front Open

DMP Factory 500 Printer Front Open

DMP Factory 500 Depowdering Module Side

DMP Factory 500 Depowdering Module Side

DMP Factory 500 Depowdering Module Open

DMP Factory 500 Depowdering Module Open

DMP Factory 500 Powder Recycling Module Open

DMP Factory 500 Powder Recycling Module Open

DMP Factory 500 Parking Module Side

DMP Factory 500 Parking Module Side

3DXpert® software

3DXpert® software

- DMP Factory 500 Full Modules

- DMP Factory 500 Printer Front Closed

- DMP Factory 500 Printer Side Closed

- DMP Factory 500 Printer Front Open

- DMP Factory 500 Depowdering Module Side

- DMP Factory 500 Depowdering Module Open

- DMP Factory 500 Powder Recycling Module Open

- DMP Factory 500 Parking Module Side

- 3DXpert® software

1/

DPM Factory 500

Main specifications

Main specifications |

|

| Printer Module uncrated | 3010 x 2350 x 3160 mm |

| Printer Module weight | 8232 kg (excluding RPM) |

| Depowdering Module uncrated | 3000 x 2530 x 3300 mm |

| Powder Recycling Module uncrated | 1935 x 2262 x 2521 mm |

| Removable Print Module | 1120 x 850 x 1400 mm |

| Parking Module | 1450 x 1780 x 1850 mm |

Printing specifications

Printing specifications |

|

| Laser type | 3 x 500 W / Fiber laser |

| Laser wavelength | 1070 nm |

| Layer thickness, range, preset | Adjustable, min. 2 μm, max.200 μm, typ. 60 μm |

| Build envelope | 500 x 500 x 500 mm (height inclusive of build plate) |

| Material deposition | Soft blade recoater |

| Repeatability (related to actual printed jobs) | Δx (3σ) = 75um, Δy (3σ) = 75um, Δz (3σ) = 75um |

| Minimum feature size | 300 μm |

| Accuracy |

± 0.1-0.2% with ± 100 μm minimum |

Materials

Materials |

| LaserForm Ni718, LaserForm Ti Gr23, LaserForm AlSi10Mg (other materials available upon request) |

Discover our DMP 500 video

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Download area

- DMP Factory 500 (PDF/ 3 MB)

- 3DXpert for AM (PDF/ 9 MB)

- 3DXpert Build Simulation (PDF/ 1 MB)

- 3DXpert version 17 (PDF/ 345 KB)

- DMP Materials Datasheet (PDF/ 16 MB)

- DMP Materials Safety Datasheet (PDF/ 4 MB)

- DMP Advanced Service Package Flyer (PDF/ 292 KB)

- UNITED MACHINING Additive Solutions brochure (PDF/ 4 MB)

- AM Materials Flyer (PDF/ 1 MB)