Mold cavity insert

GF Machining Solutions' high-speed Milling offers a solution to pre-mill the enclosure molding inserts with high contour accuracy, profile integrity and surface finish:

- Achieve small profiles and smooth contours with HSK E-40 42'000 rpm Spindle

- Obtain sub-micron surface finish for optimized automated post-milling process for groove machining

- Manufacture through a single process to achieve complete shape and features on molding inserts

Cavity structuring with Laser technology

Our Laser texturing technology offers a solution to structure molding inserts with unique grove and branding elements:

- Simplified, smarter and automated manufacturing process for insert texturing

- Single setup for the manufacturing of grooves, insert blasting and logos

- Fully digital process chain to transition special textures into product realization

Cavity structuring with precision Die-sinking EDM

Cap insert features can be replicated with a Die-sinking EDM solution to create grooves. Our FORM P 350 with Intelligent Speed Power Generator (ISPG) and polishing technology enables mold makers to:

- Achieve a perfect shape on cap insert with no deviation

- Save electrode costs and boost productivity with iGap features

- Obtain outstanding groove edge sharpness and uniform surface integrity

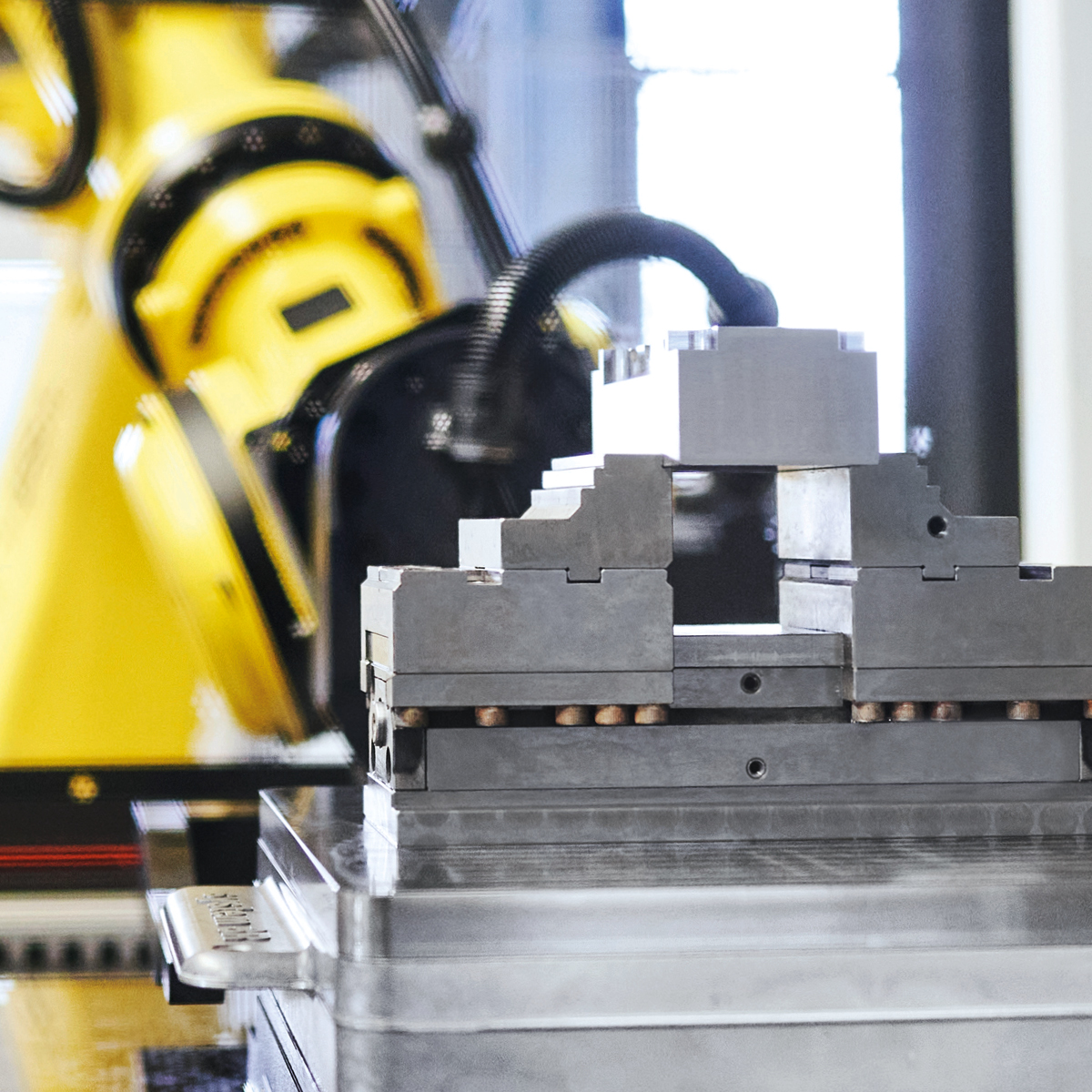

Collapsible core

Collapsible core systems are designed for demolding of engineered plastic parts with internal threads and undercuts. Our high-accuracy Wire-cutting EDM solution enables machining of accuracy slider components:

- Sharp edges for smooth core assembly and ejection process

- Accurate slots and guideways for zero play assembly

- Perfect taper control within ± 1.5°