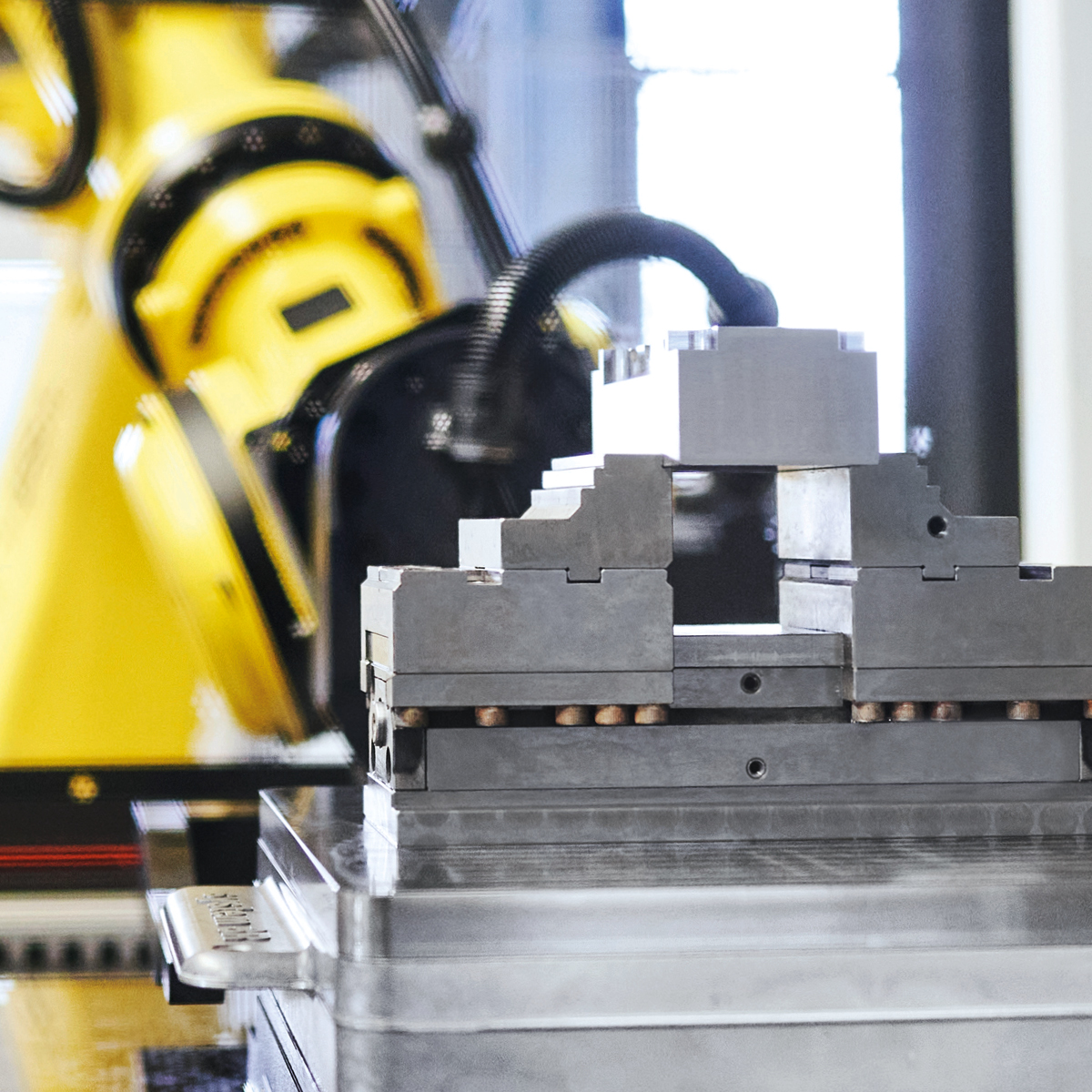

Stamping tool for battery cathode and anode leads

Battery, fuel cell and other electrical power devices require the creation of cathode and anode leads through progressive stamping technology. These leads directly impact the energy efficiency and transfer rate, thus require extremely accurate tooling with fine edges and high surface finish. With our Wire EDM machines:

- Enable machining of carbide and steel with an integrated technology

- Obtain high accuracy on machined components due to robust machine design

- Achieve superb surface finish with Thin Wire technology

- Control the quality with integrated advanced systems such as ISPS (Intelligent Spark Protection System), IVU (Integrated Vision Unit) and AWC (Automatic Wire Changer)

Micro-scale lead features

To reach miniaturization and energy efficiency, modern battery systems used in electric vehicles, solid state devices and fuel cells need micro-scale lead features. Our state-of-art high-end Wire EDM with Thin Wire technology allows the creation of tooling suitable for these applications.

- Accurate machining of smallest geometries

- Achieve easy machining with sharp micro-cutting profiles

- Production control over fine wire machining with a simple and stable process

- Quality control with X-treme precision and calibration standards

Mold and die tooling for battery

Our Milling technology provides solutions for the production of complete mold and die tools while catering the needs for base plate, spacer plate, hot runner mounting plate or insert plates machining, in addition to high-accuracy inserts and electrodes. With our high-speed and high-performance Spindle technology Milling solution:

- Achieve high material removal rate with robust machine design and Step-Tec Spindle designed for mold machining

- Get a high surface finish and minimize any manual operation with thermally stable machining at high speed

- Control your production process and machining repeatability thanks to integrated automation