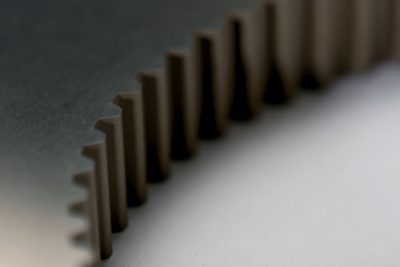

GF Machining Solutions helps you meet the technical and business challenges in the dynamic environment of electronic components and ICT manufacturing. Discover our best-in-class solutions based on decades of customer satisfaction.

Discover our expertise in Electronic components and ICT

Other key applications

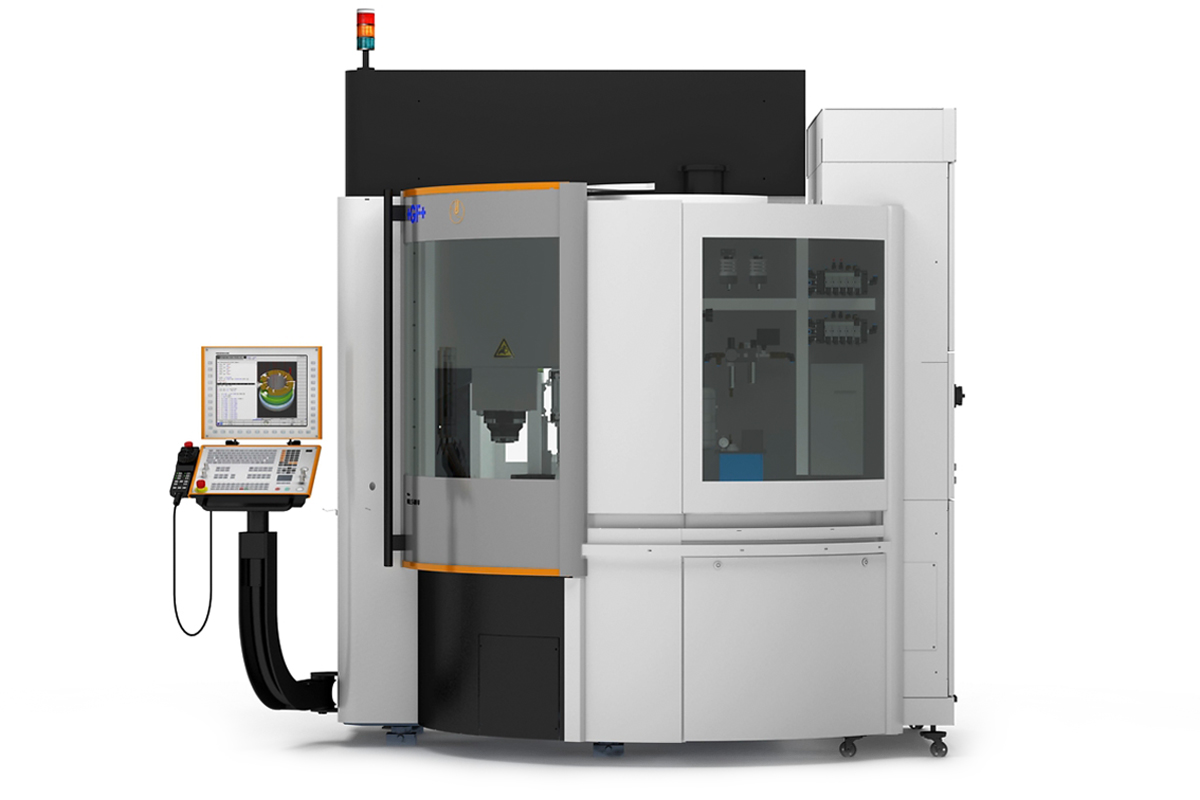

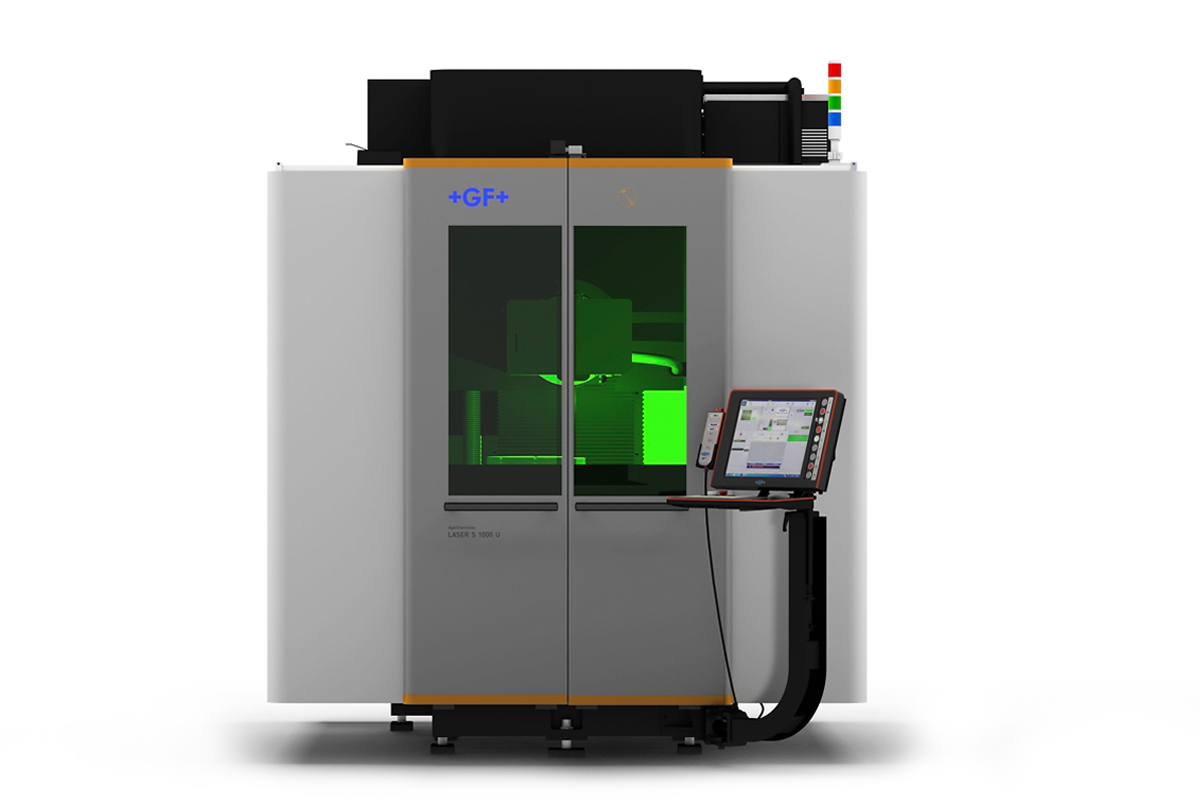

Our technologies

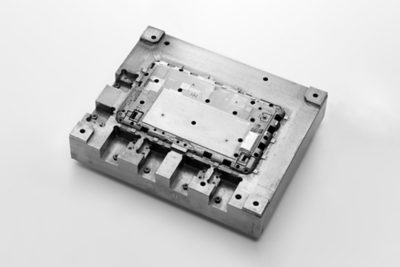

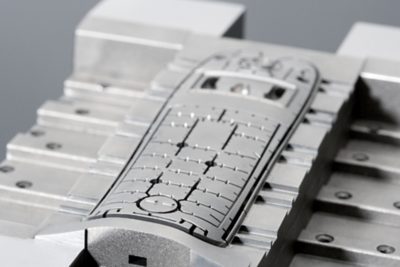

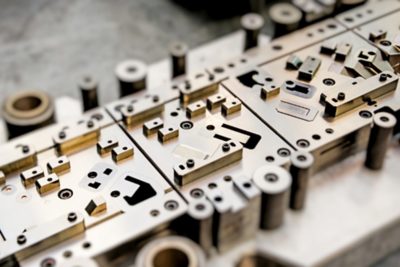

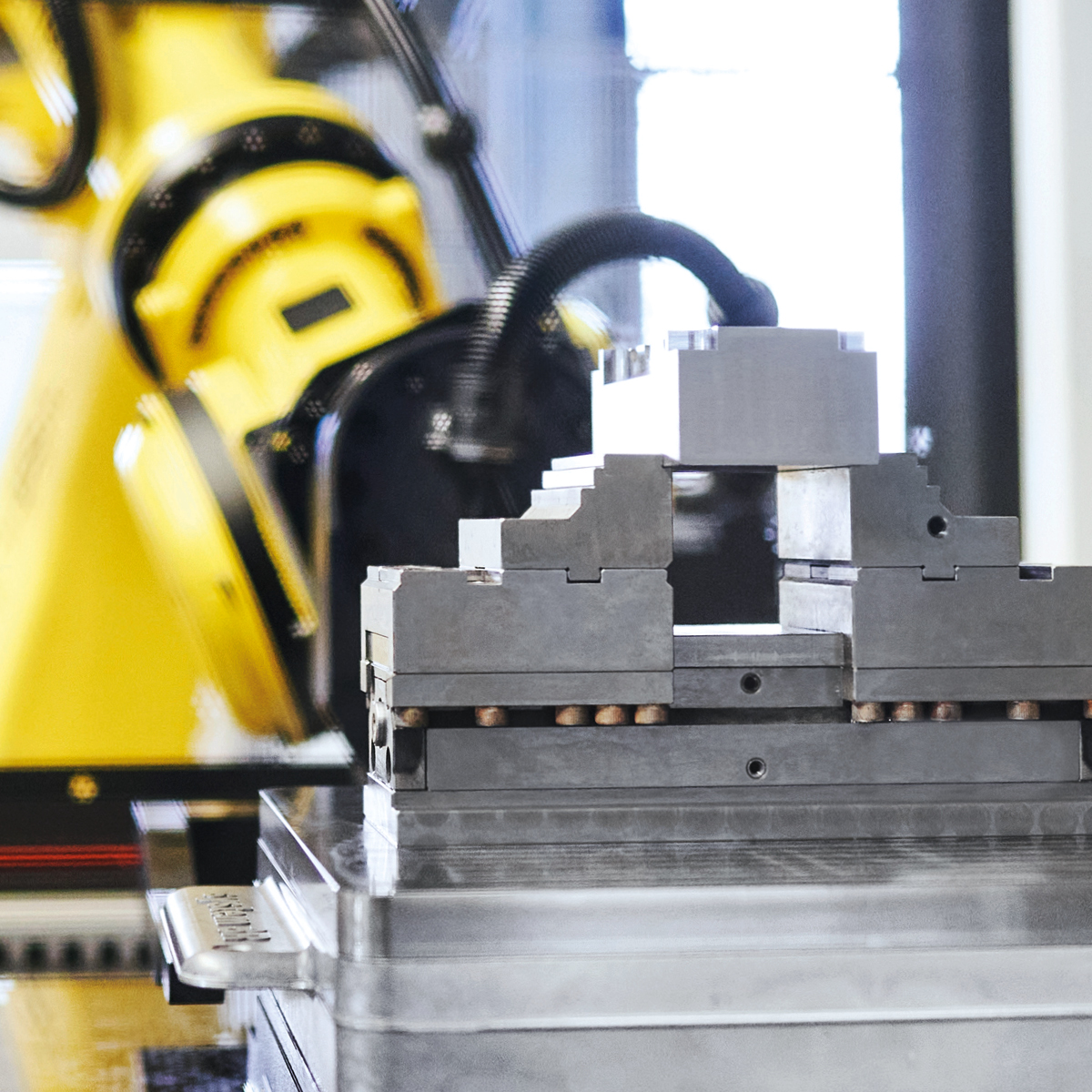

Solution approach for connectors

In today's competitive world, the unique consumer demands, price constraints and quick delivery are pushing the mold makers to design tools with increased accuracy, at reduced cost and higher production rates. To facilitate these demands GF Machining Solutions offers to adapt the overall connector manufacturing process based on true electrode geometry.

Please accept all cookies to view the youtube video content.