DMP Flex 350 front open

DMP Flex 350 front open

- DMP Flex 350 front

- AM process

- DMP Flex 350 front open

- 3DXpert® software

- DMP Flex 350 side

- Hip cups

- DMP Flex 350 side open

- 3DXpert® all-in-one software

*Height inclusive of build plate

DMP Factory 350

Ensure maximum safety and powder integrity

DMP Factory 350 has an integrated powder management system with high-performance sieving and automated powder conveyance. The O2-free atmosphere of the powder workflow guarantees highest part quality as well as maximum powder usage and minimizes user powder contact.

- DMP Factory 350 front

- DMP Factory 350 side

DMP Flex/Factory 350 features

Unique vacuum chamber concept

Consistent, low O2 environment

Reduce your cost to part by avoiding non-quality scrap issues and get access to higher-margin regulated markets like aerospace and medical, where constant quality is a requirement for certified parts. Discover these benefits, thanks to our consistently low 02 environment in the printer to guarantee consistent powder quality for high-quality parts.

Bi-directional recoating

Boost your productivity

Accelerate your productivity to reduce your cost per part, thanks to our high-performance, bidirectional recoating system that consistently and accurately deposits a fresh powder layer on each pass to reduce the time that the lasers are active.

DMP Monitoring

Real-time process monitoring

DMP Monitoring allows users to see, analyze, understand and fine-tune their metal AM process with unprecedented capability. The DMP Monitoring toolset for enhanced quality control includes real-time process monitoring, synchronized images of the melt pool and powder bed, synchronized images of active and archived jobs for comparison, and a toolset for analyzing the magnitude of a subject area, enabling:

- Real-time, in-build data collection and visualization

- Post-build process analysis

- Build parameter optimization

3DXpert

All-in-one integrated software for Additive Manufacturing

3DXpert is an all-in-one integrated software to prepare, optimize and manufacture 3D CAD models using additive manufacturing (AM). Supporting every step of the additive manufacturing workflow from design to post-processing, 3DXpert streamlines your process to quickly and efficiently transition from a 3D model to a successfully printed part.

DMP Flex 350 features

Removable print module

Increase your flexibility

Improve your flexibility and productivity with a Removable Print Module (RPM) that can be replaced with another RPM just after a job is finished. This also positively impacts the total cost of ownership because you can reduce downtime when switching from one material to another material by having one dedicated RPM per material.

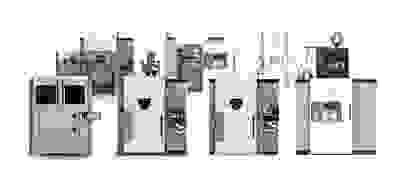

DMP Flex/Factory 350 Dual

The DMP Flex 350 and DMP Factory 350 systems now come in a two-laser configuration, reducing build times by up to 50 percent. Boosting productivity while maintaining high quality and repeatability yields lower operational costs.

New features

New Dual Laser (2x 500 W) configuration

Increases productivity and reduces costs

New pre-filter cyclone system

Decreases filter costs

New heated platform

Reduces risk cracking of specific building jobs

Enhanced Removable Print Module

Enables easy, fast and consistent calibration

Enhanced coater accuracy

Decreases machine-to-machine variability

Enhanced coater cutting tool

Decreases operator errors and machine-to-machine variability

New back powder tray on exhaust

Reduces loss of powder during cleaning

New Railroad UI in Operator mode

Reduced operator error

DMP Flex 350 Dual front

DMP Flex 350 Dual front

DMP Flex 350 Dual side

DMP Flex 350 Dual side

DMP Factory 350 Dual front

DMP Factory 350 Dual front

DMP Factory 350 Dual side

DMP Factory 350 Dual side

- DMP Flex 350 Dual front

- DMP Flex 350 Dual side

- DMP Factory 350 Dual front

- DMP Factory 350 Dual side

DMP Flex 350 Triple

New features

Triple Laser (3x 500W) configuration

Increased productivity and reduced costs

3-axis scanning systems with dynamic focusing

Better accuracy and higher productivity on large build areas

Full field laser

It allows to build large seamless parts

Configurable 275x275x420mm or 350x350x350mm RPM build volume

Perfectly matching the specific application requirements

Specifications

DPM Flex/Factory 350

Main specifications

Main specifications |

|

| Machine dimensions | 2370 x 2400 x 2869 mm (DMP Flex 350 in printing condition) 2370 x 2400 x 3470 mm (DMP Factory 350 in printing condition) |

| Machine weight | 4200 kg |

Printing specifications

Printing specifications |

|

| Laser type | 1 or 2 or 3 x 500 W / Fiber laser |

| Laser wavelength | 1070 nm |

| Layer thickness, range, preset | Adjustable, min. 5 μm, typical: 30, 60, 90 μm |

| Build envelope | 275 x 275 x 420 mm (height inclusive of build plate) – DMP 350 Single / Dual / Triple laser 350 x 350 x 350 mm - DMP 350 Triple laser |

| Material deposition | Soft blade recoater |

| Minimum feature size |

200 μm |

| Minimum wall thickness |

150 μm |

| Accuracy |

± 0.1-0.2% with ± 100 μm minimum |

| Repeatability (related to actual printed jobs) |

Δx (3σ) = 60 μm, Δy (3σ) = 60 μm, Δz (3σ) = 60 μm |

Materials

Materials |

Aluminum alloys: LaserForm AlSi7Mg0.6, LaserForm AlSi10Mg, Certified Al6061-RAM2, Certified Scalmalloy, Certified Aheadd CP1 Titanium alloys: LaserForm Ti Gr1, LaserForm Ti Gr5, LaserForm Ti Gr23 Steels: LaserForm 316L, LaserForm 17-4PH, LaserForm Maraging Steel, Certified Böhler M789 Cobalt-Chrome alloys: LaserForm CoCrF75 Nickel alloys: LaserForm Ni718, LaserForm Ni625, Certified HX, Certified GRX-810 Refractory metals: Certified Tungsten, Certified C-103 Copper alloys: Certified CuCr1Zr, Certified CuCr2.4, Certified CuNi30, Certified GRCop-42, Certified Pure Cu |

Discover our DMP Flex 350 video

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Download area

- DMP Flex/Factory 350 brochure (PDF/ 7 MB)

- 3DXpert All-in-One Integrated Software (PDF/ 9 MB)

- 3DXpert Build Simulation (PDF/ 1 MB)

- 3DXpert version 17 (PDF/ 345 KB)

- DMP Materials Datasheet (PDF/ 16 MB)

- DMP Materials Safety Datasheet (PDF/ 4 MB)

- DMP Advanced Service Package Flyer (PDF/ 292 KB)

- GF Additive Solutions brochure (PDF/ 4 MB)

- AM Materials Flyer (PDF/ 1 MB)