GF Machining Solutions enables you to create products that provide unique value for patients, reduce your manufacturing risk, improve your efficiency, and set you apart from the competition.

Discover our expertise in medical

Our Medical technologies

Our solution for medical implants include Milling, EDM, Laser, Software, Tooling and Automation, and Customer Services

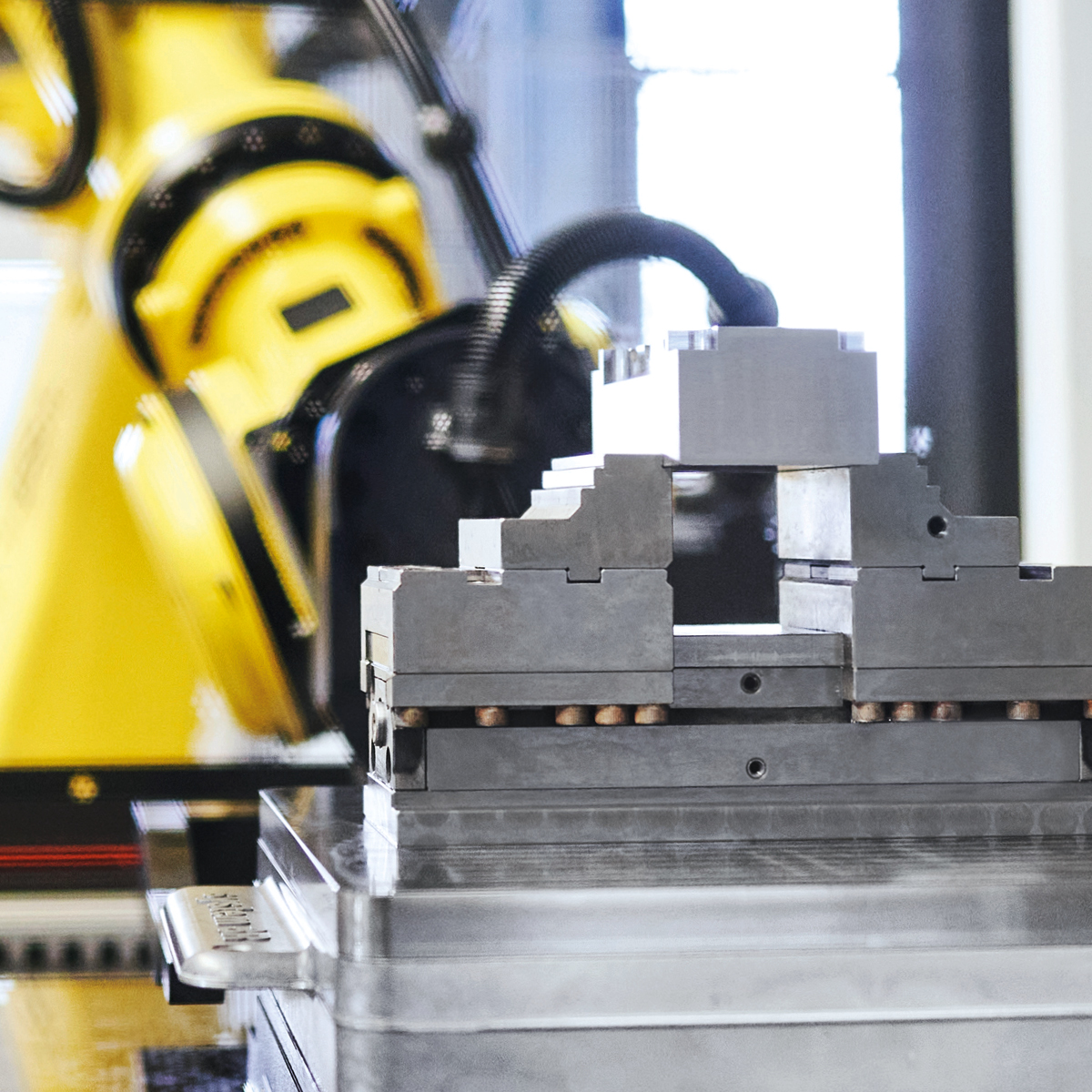

MILL E 500 U - Milling machine

MILL E 500 U - Milling machine

With a full portfolio of spindles we ensure best in class surface finishes and adherence to tolerance

With a full portfolio of spindles we ensure best in class surface finishes and adherence to tolerance

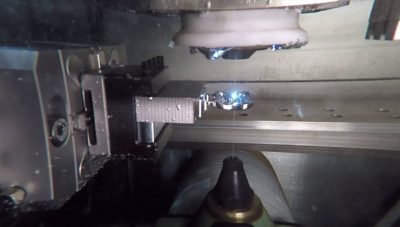

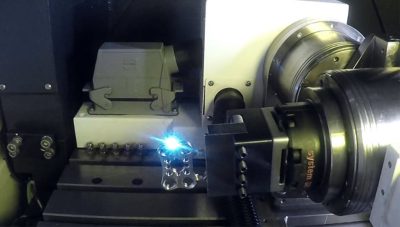

CUT P 350 - Wire EDM machine

CUT P 350 - Wire EDM machine

With our latest generation spark generator we increase cutting speeds and obtain a better surface finish

With our latest generation spark generator we increase cutting speeds and obtain a better surface finish

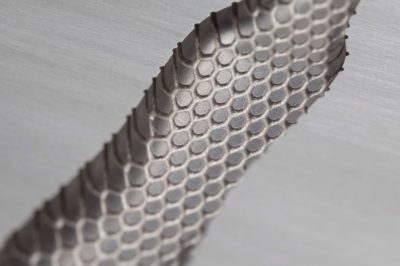

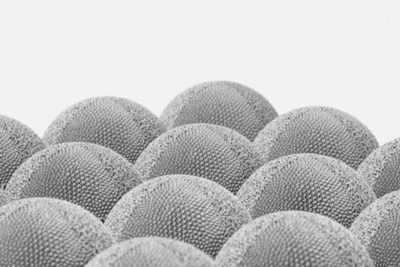

LASER P 400 U - Laser texturing machine

LASER P 400 U - Laser texturing machine

Laser blasting is a fully digital

Laser blasting is a fully digital

S3R pallets equipped with RFID tags provide accurate position in each work cell

S3R pallets equipped with RFID tags provide accurate position in each work cell

GF Machining Solutions Custmer Services provide you with Operations Support

GF Machining Solutions Custmer Services provide you with Operations Support

See the real time status of your GF machine on your smartphone - with rConnect

See the real time status of your GF machine on your smartphone - with rConnect

- Our solution for medical implants include Milling, EDM, Laser, Software, Tooling and Automation, and Customer Services.

- MILL E 500 U - Milling machine

- With a full portfolio of spindles we ensure best in class surface finishes and adherence to tolerance

- CUT P 350 - Wire EDM machine

- With our latest generation spark generator we increase cutting speeds and obtain a better surface finish

- LASER P 400 U - Laser texturing machine

- Laser blasting is a fully digital, repeatable process that simplifies manufacturing

- S3R pallets equipped with RFID tags provide accurate position in each work cell

- GF Machining Solutions Custmer Services provide you with Operations Support, Machine Support and Business Support

- See the real time status of your GF machine on your smartphone - with rConnect

1/

An automated, fully integrated solution approach to medical device manufacturing

Please accept all cookies to view the youtube video content.