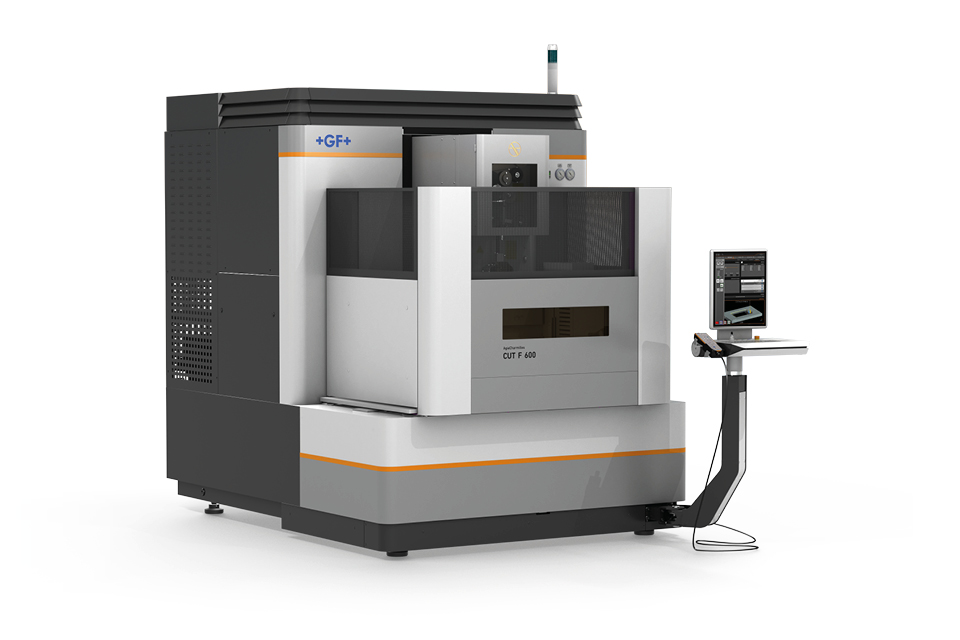

Swiss made and the culmination of 70 years of EDM engineering advancements, the CUT F delivers an unmatched blend of versatility and reliability. Its integrated suite of advanced modules - including ISPS/Spark Track and Turbo Tech - offers practical solutions to streamline operations, enhance precision, and reduce manual intervention.

A praised HMI

Intuitive and adaptable, our UNIQUA interface remains effective across various skill levels and operative approaches.

Full discharge control

Our Intelligent Power Generator (IPG) delivers clean, repeatable impulses granting optimal energy employment.

A clean cut(ter)

By minimizing manual intervention, Automatic Wire Threading (AWT) shortens equipment setup times, increasing productivity.

Investment protection

In the case of a collision, Integrated Collision Protection (ICP) preserves your machine's health.

Tracking technology

For superior efficiency, ISPS/Spark Track monitors each discharge’s position and concentration.

Lower consumption

iWire ensures optimal use of consumables while eliminating waste.

The machine that can do it all!

Please accept all cookies to view the external content.

Plastic mold for ICT

Even tasked with complex geometries, the CUT F delivers excellent tapers. Thanks to our innovative ISPS/Spark Track module, wire breakage is carefully avoided.

Plate for stamping tooling

Achieve a pitch accuracy of ±2.5 μm on any stamping plate, and a 20% reduction in both wire consumption (with iWire) and setup times (with Turbo Tech).

Video

Curious to know how it can enhance your shop floor? Get in touch!

Please accept all cookies to view the external content.