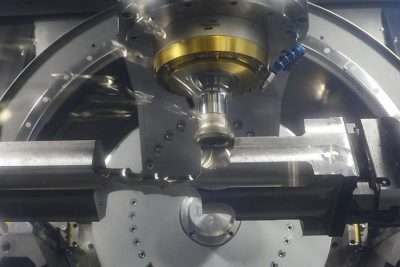

- Highest profile accuracy and trailing edge quality in shortest machining time

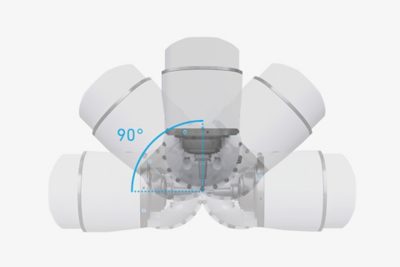

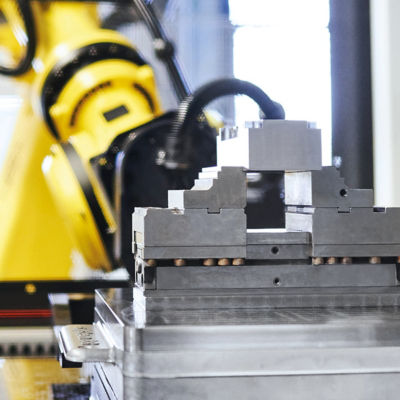

- Complete machining in one setup, including bar feeding, five-axis Milling, turning, root machining, threading, chamfering, engraving and brushing

- Rigid, compact layout of all axes for high jerk machining

- Turn-key solution including specialized TurboSoft plus CAM software

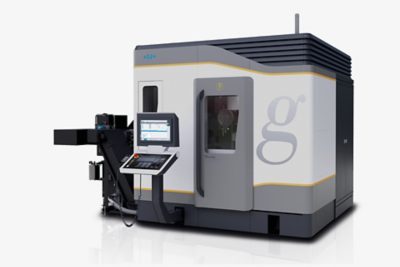

Liechti go-Mill 350 / Turbomill series

Please accept all cookies to view the external content.

Blade process Manuf 2

Blade process Manuf 2

Blade process Manuf 4

Blade process Manuf 4

- Blade process Manuf 1

- Blade process Manuf 2

- Blade process Manuf 3

- Blade process Manuf 4

- Blade process Manuf 5

- Blade process Manuf 6

1/

Turbomill 500g

Setting the new standard of blade machining

Please accept all cookies to view the youtube video content.

Improve your overall equipment efficiency

- Reduce your cycle times

- Increase your quality rate

- Reduce your maintenance costs

- One single source provider