Main specifications

Main specifications |

|

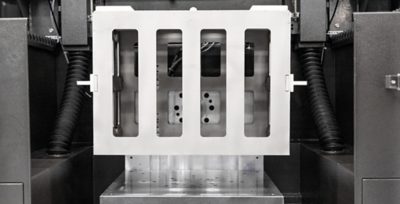

| Dimensions of complete equipment (WxDxH) | 1700x2953x2224 mm |

| Dimensions of complete equipment with lamp (WxDxH) | 1700x2953x2608 mm |

| Dimensions of complete equipment with extraction system (WxDxH) | 1700x2953x2708 mm |

| Total weight of equipment without dielectric | 3220 |

| Total weight of equipment with dielectric | 4120 |

| Tank volume | 900L |

Cutting specifications

Cutting specifications |

|

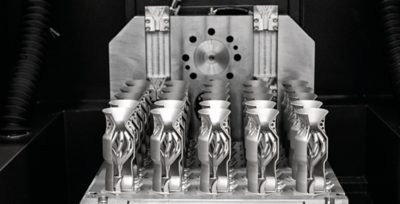

| Max. part dimensions |

510x510x490 |

| Max. part weight (base plate + parts) | 500 kg |

| Y, Z Travel | 650x200 mm |

| Y, Z measurement resolution | 0.1 μm |

| Speed of axis movement | 0-2000 mm/min |

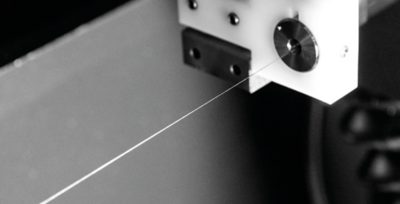

| Wire type | Molybdenum 0.2 mm |

| Max.machining speed | 240 mm2/min |

| Min. roughness | 6 μm (Ra) (according to geometries and technologies) |

| Accuracy | ±0.1 mm |

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.