- ML-5 front

- ML-5 side

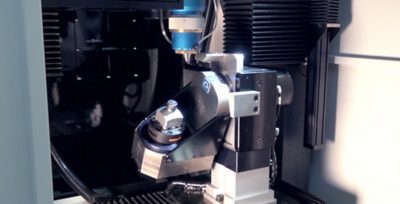

- Five-axis configuration 1

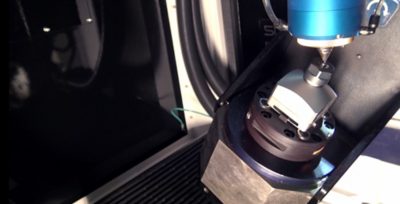

- Five-axis configuration 2

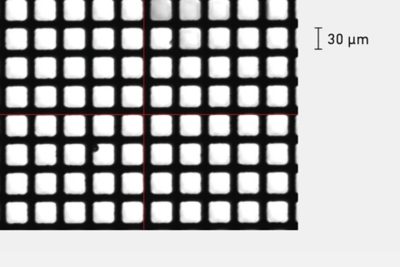

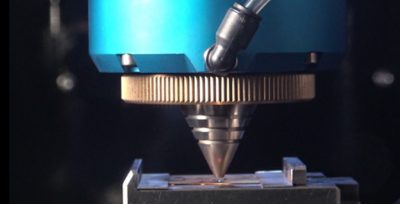

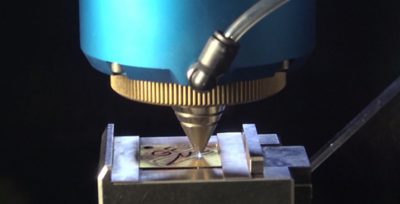

- Femtosecond Laser cutting

- Straight sidewall cutting

1/

ML-5

Machine

Machine |

|

Machine dimensions* |

2010 x 2450 x 2720 mm 79.1 x 96.5 x 107.2 in |

Machine weight |

2730 kg 6019 lbs |

Yb: KGW (Diode-pumped) |

40/80 W |

Accessory cabinet dimensions * |

1000 x 1200 x 1580 mm 39.5 x 47.1 x 62.2 in |

Electrical and Pneumatic supply

Electrical and Pneumatic supply |

|

Nominal power |

7.2 kVA |

Air pressure |

7 bar 0.68 MPa |

Required air output flow |

280 l/min 74.8 gal/min |

Axes

Axes |

|

X, Y, Z travels (3-axis) |

280 x 350 x 260 mm 11.02 x 13.78 x 10.24 in |

X, Y, Z travels (5-axis) |

120 x 350 x 260 mm 4.72 x 13.78 x 10.24 in |

A (tilt) travel |

+95° to -125° |

| C (rotary) travel | 360° (continuous) |

* Width x length x height

Discover our ML-5 video

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.