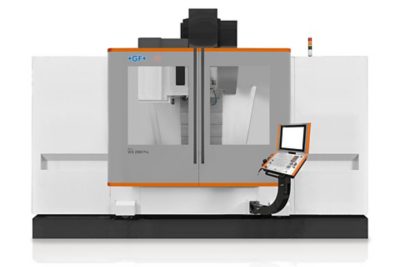

MILL E 800 - MILL E 1200

Please accept all cookies to view the external content.

MILL E 800

MILL E 800

MILL E 800

MILL E 800

MILL E 1200

MILL E 1200

MILL E 1200 - open

MILL E 1200 - open

MILL E 1200 - open

MILL E 1200 - open

- MILL E 800

- MILL E 800

- MILL E 1200

- MILL E 1200

- MILL E 1200 - open

VCE 1400/1600/2000 Pro Series– Ideal efficient milling for parts up to 2 meters

Please accept all cookies to view the external content.

The affordable bestseller VCE 1400/1600/2000 Pro series ramp up you production of simple to complex molds, dies prototypes and singles parts up to 2 meters and 3 tones. Whether you're a job shop, mold and die maker, small to medium-sized operation, prototype manufacturer or producer of single parts, this reasonably priced bestseller delivers always the expected results and even more. Get s a stiff machine base and high-tech key components –along with CNC, Spindle and accuracy-supporting linear scales included –to drive your success. Experience easy set-up, excellent ergonomics, a choice of X travel from 1,400 to 2,000 mm to machine a wide variety of material and execute a vest variety of application.

Please accept all cookies to view the external content.

MILL E 800

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 850 x 600 x 600 mm |

| Feed rate X/Y/Z | 15 m/min |

| Rapid feed rate X,Y / Z | 40 m/min |

| Working table | T-slot table 1050 x 600 mm |

| Table load | 1000 kg |

| Working spindle | 20'000 rpm - HSK-A63 16'000 rpm - HSK-A63 & ISO & BT40 12'000 rpm - ISO & BT40 |

| Tool magazine | 30 / 60 pockets |

| Footprint | |

| Automation | On request: System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

MILL E 1200

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 1250 x 600 x 600 mm |

| Feed rate X/Y/Z | 15 m/min |

| Rapid feed rate X,Y / Z | 40 m/min |

| Working table | T-slot table 1450 x 600 mm |

| Table load | 1500 kg |

| Working spindle | 20'000 rpm - HSK-A63 16'000 rpm - HSK-A63 & ISO & BT40 12'000 rpm - ISO & BT40 |

| Tool magazine | 30 / 60 pockets |

| Footprint | |

| Automation | On request: System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

VCE 600 Pro

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 600 x 500 x 540 mm |

| Feed rate X/Y/Z | 40 m/min |

| Working table | 700 x 500 mm |

| Table load | 800 kg |

| Working spindle | 16'000 rpm - HSK-A63 / ISO & BT 40 10'000 rpm - ISO & BT40 |

| Tool magazine | 24 / 40 pockets |

| Footprint | |

| Automation | System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

VCE 800 Pro

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 800 x 500 x 540 mm |

| Feed rate X/Y/Z | 40 m/min |

| Working table | 910 x 500 mm |

| Table load | 1100 kg |

| Working spindle | 16'000 rpm - HSK-A63 / ISO & BT 40 10'000 rpm - ISO & BT40 |

| Tool magazine | 24 / 40 pockets |

| Footprint | |

| Automation | System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

VCE 1000 Pro

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 1020 x 560 x 600 mm |

| Feed rate X/Y/Z | 40 m/min |

| Working table | 1000 x 560 mm |

| Table load | 1350 kg |

| Working spindle | 16'000 rpm - HSK-A63 / ISO & BT 40 10'000 rpm - ISO & BT40 |

| Tool magazine | 24 / 40 / 60 pockets |

| Footprint | |

| Automation | System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

VCE 1200 Pro

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 1200 x 600 x 675 mm |

| Feed rate X/Y/Z | 32 / 24 m/min |

| Working table | 1220 x 620 mm |

| Table load | 1700 kg |

| Working spindle | 16'000 rpm - HSK-A63 / ISO & BT 40 10'000 rpm - ISO & BT40 |

| Tool magazine | 24 / 40 / 60 pockets |

| Footprint | |

| Automation | System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

VCE 1400 Pro

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 1400 x 650 x 675 mm |

| Feed rate X/Y/Z | 32 / 24 m/min |

| Working table | 1400 x 620 mm |

| Table load | 1700 kg |

| Working spindle | 16'000 rpm - HSK-A63 / ISO & BT 40 10'000 rpm - ISO & BT40 |

| Tool magazine | 24 / 40 / 60 pockets |

| Footprint | |

| Automation | System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

VCE 1600 Pro

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 1600 x 900 x 800 mm |

| Feed rate X/Y/Z | 24 / 20 m/min |

| Working table | 1700 x 850 mm |

| Table load | 2000 kg |

| Working spindle | 16'000 rpm - HSK-A63 / ISO & BT 40 10'000 rpm - ISO & BT40 6'000 rpm - ISO & BT50 |

| Tool magazine | 40 / 60 pockets - HSK-A63 30 / 40 / 60 pockets - ISO & BT40 24 / 40 pockets - ISO & BT50 |

| Footprint | |

| Automation | System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

VCE 2000 Pro

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 2000 x 900 x 800 mm |

| Feed rate X/Y/Z | 20 m/min |

| Working table | 2100 x 850 mm |

| Table load | 3000 kg |

| Working spindle | 16'000 rpm - HSK-A63 / ISO & BT 40 10'000 rpm - ISO & BT40 6'000 rpm - ISO & BT50 |

| Tool magazine | 40 / 60 pockets - HSK-A63 30 / 40 / 60 pockets - ISO & BT40 24 / 40 pockets - ISO & BT50 |

| Footprint | |

| Automation | System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |