Sustainability

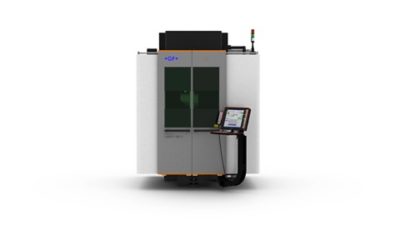

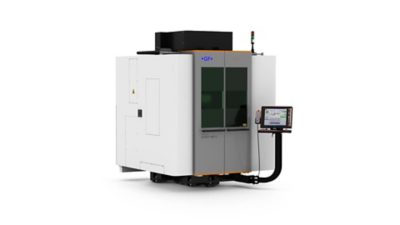

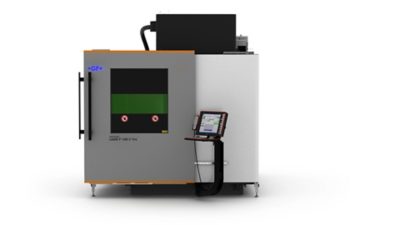

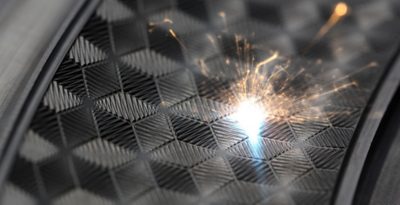

The newest generation of CHARMILLES LASER P series can achieve significant reductions in energy consumption, up to 20% on a daily basis. An optimized use of compressed air, additional electrical cabinet cooling and water-cooled refrigeration for Laser sources have made this achievement possible.