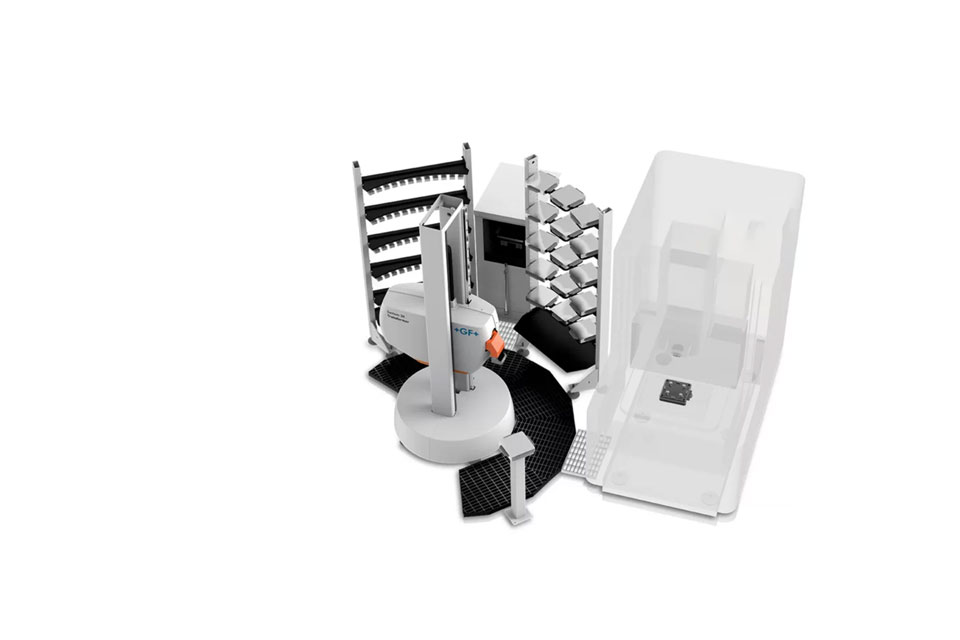

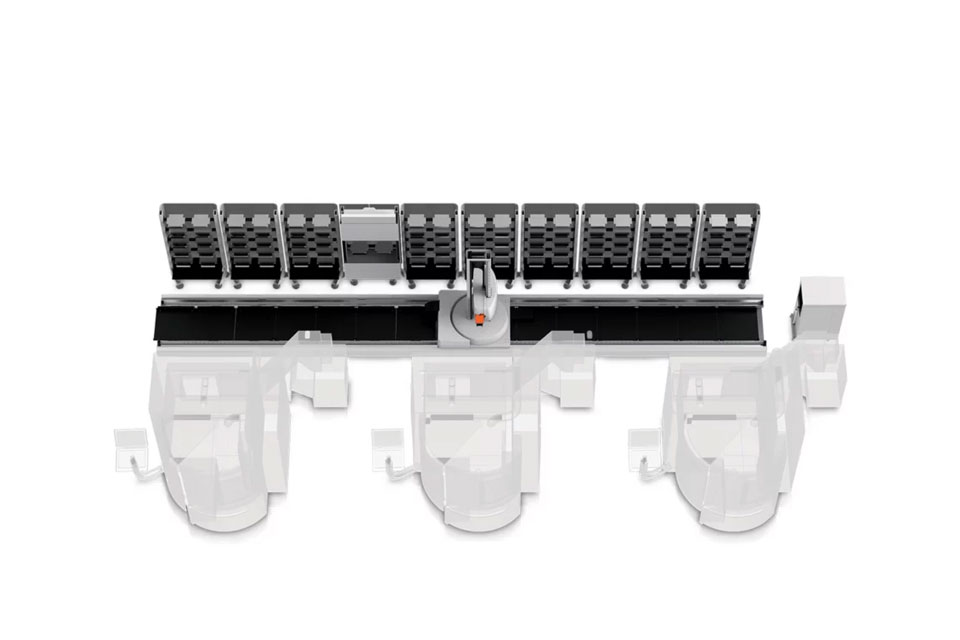

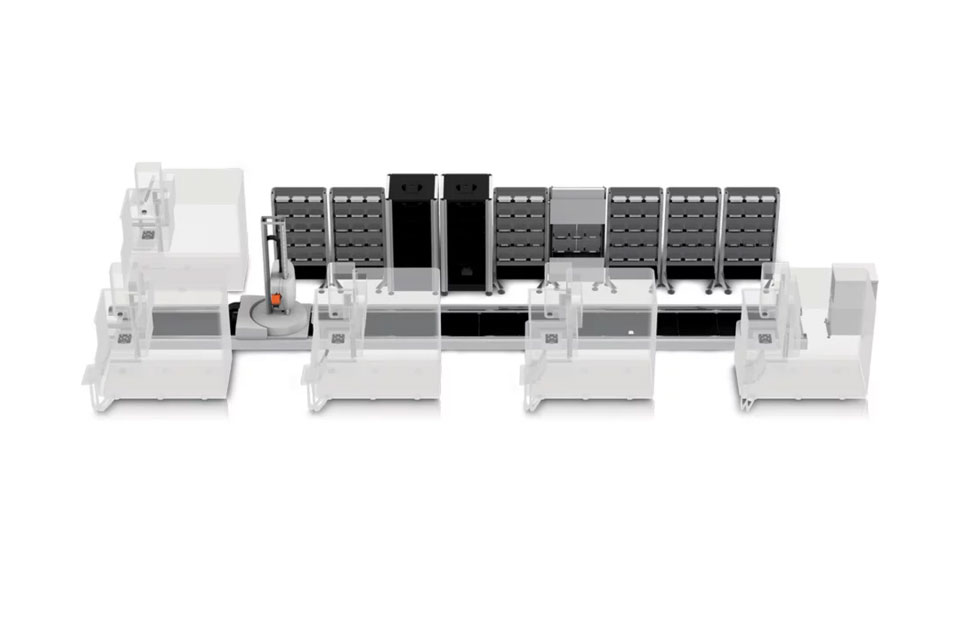

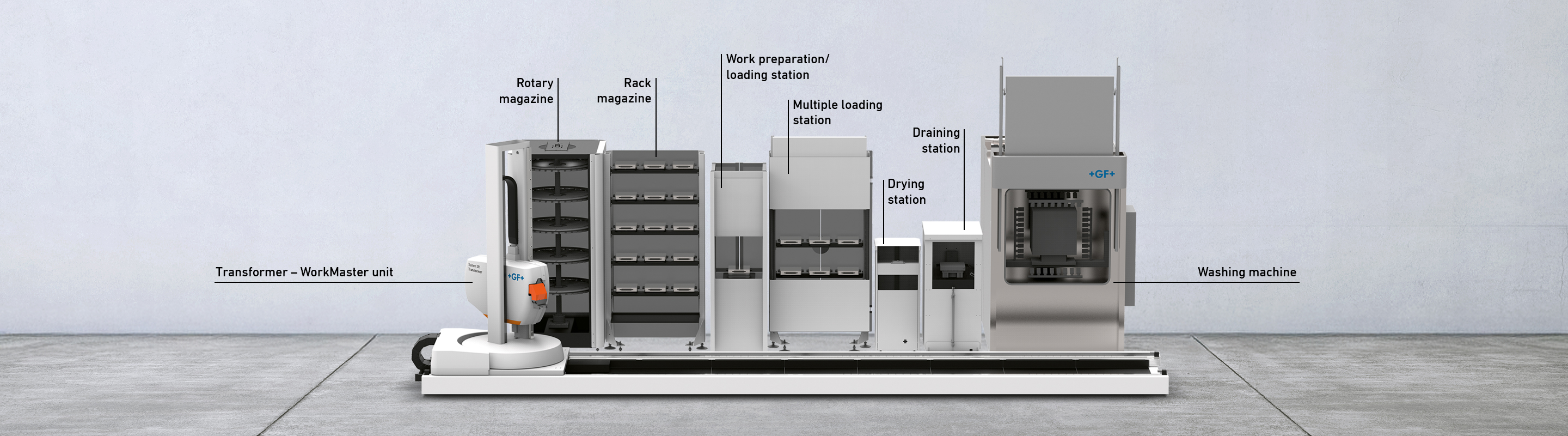

SYSTEM 3R – Transformer 3-Axis robot: Scalable Automation to transform your business

Scalable Automation solutions for various types of machines. With standardized modules allow for cost-effective yet flexible Automation. Are you ready to begin, add or extend your automation?