Please accept all cookies to view the external content.

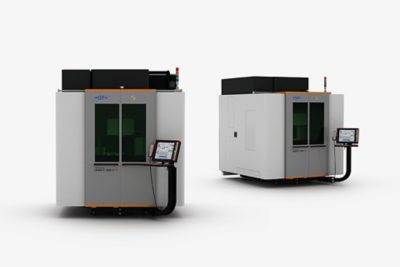

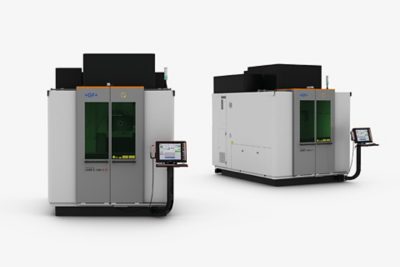

LASER S 1000/1200/2500 U fs

Please accept all cookies to view the external content.

Please accept all cookies to view the youtube video content.

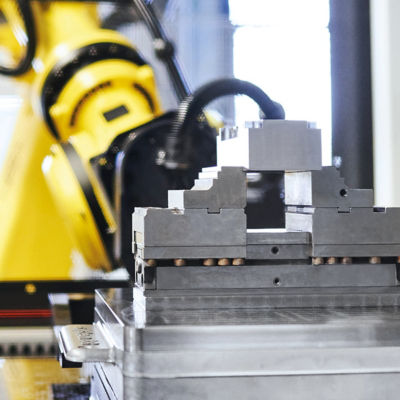

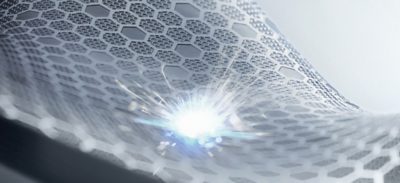

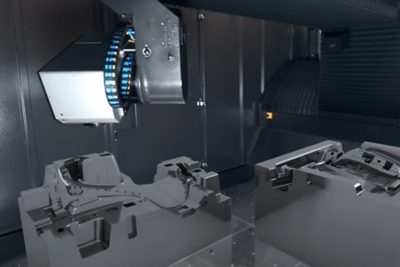

Ultrashort pulse laser: the power to create the finest details at the speed of light

The combination of our breakthrough Laser femtosecond ablation technology and our dedicated software solutions allow the CHARMILLES LASER S to reach a new level of performance. That's the power of ultrashort pulse laser.

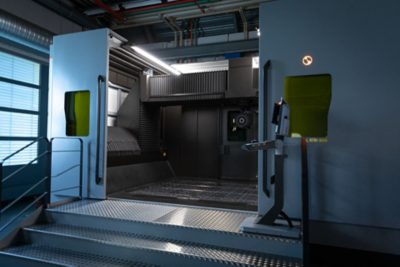

CHARMILLES LASER S 1000 U fs

CHARMILLES LASER S 1000 U fs

CHARMILLES LASER S 1200 U fs

CHARMILLES LASER S 1200 U fs

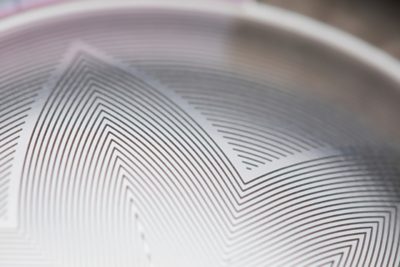

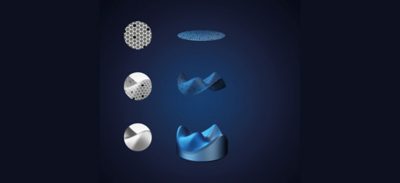

Fine line patterns and textures

Fine line patterns and textures

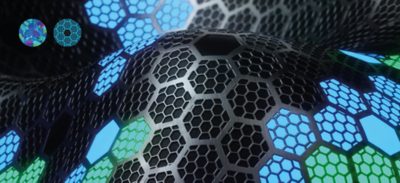

Fine curves

Fine curves

Unique brush effects

Unique brush effects

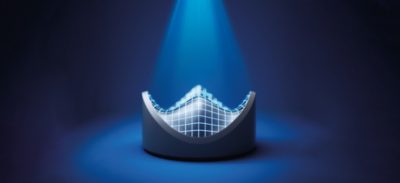

Sharper geometries with femtosecond Laser

Sharper geometries with femtosecond Laser

Microengraving with femtosecond Laser

Microengraving with femtosecond Laser

Finest details with femtosecond Laser

Finest details with femtosecond Laser

The power of ultrashort pulse laser

The power of ultrashort pulse laser

The ideal Laser sources to meet your design expectations

The ideal Laser sources to meet your design expectations

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

LASER S 1000 U - 1200 U - 2500 U

Please accept all cookies to view the external content.

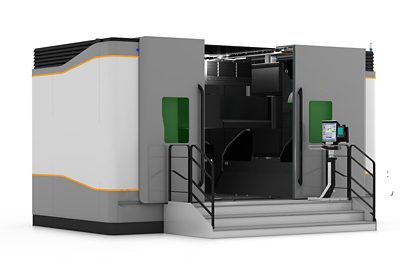

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 1000 U

- Geometrical patterns

- Perfect texture execution

- Geneva RD

- Digital Technology

- Multi process

- CHARMILLES LASER S 1200 U

- New grain

- Large marketing field

- Product design

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

- CHARMILLES LASER S 2500 U

Accelerated productivity with the CHARMILLES LASER S series

Specifications

CHARMILLES LASER S 1000 U

Main specifications

Main specifications |

|

Machine dimensions* |

2240 x 2678 x 2645 mm 88.2 x 105.4 x 104.1 in |

Space required for installation |

3400 x 4000 mm 133.9 x 157.5 in |

Machine weight |

6500 kg 14330 lbs |

Focal length |

FSTC100/FS163/FS255 Type |

Nanosecond pulsed Laser |

50 W Flexipulse/100 W Flexipulse |

Ultrashort pulsed Laser |

20 W Femto Flexipulse Infrared FD 100 W Femto IR FD |

Electrical and pneumatic supply

Electrical and pneumatic supply |

|

Nominal power |

8 kVA |

Air pressure |

6 bar |

Required air output flow |

300 l/min |

Printing specifications

Printing specifications |

|

X, Y, Z travels |

1000 x 550 x 880 mm 39.4 x 21.7 x 34.6 in |

Travel Laser head: A |

180 ° |

Travel machine table: B |

720 ° |

Table dimensions |

380 mm 15 in |

Distance floor to table |

925 mm 36.4 in |

Working area

Working area |

|

Max workpiece dimensions |

Ø 660 ** mm Ø 26 ** in |

Max workpiece machining height |

550 ** mm 21.7 ** in |

Max workpiece weight five axis |

150 kg 330 lbs |

Full five-axis dimensions |

Ø 510 x 480 ** mm Ø 20 x 18.9 ** in |

* Width x depth x height ** with FS163 *** with FS255 **** with FS340

CHARMILLES LASER S 1200 U

Main specifications

Main specifications |

|

Machine dimensions* |

2240 x 3404 x 2932 mm 88.2 x 134 x 115.4 in |

Space required for installation |

3500 x 5000 mm 137.8 x 196.9 in |

Machine weight |

9170 kg 19180 lbs |

Focal length |

FSTC100/FS163/FS255 Type |

Nanosecond pulsed Laser |

100 W Flexipulse |

Ultrashort pulsed Laser |

20 W Femto Flexipulse Infrared FD 100 W Femto IR FD |

Electrical and pneumatic supply

Electrical and pneumatic supply |

|

Nominal power |

8 kVA |

Air pressure |

6 bar |

Required air output flow |

300 l/min |

Printing specifications

Printing specifications |

|

X, Y, Z travels |

1200 x 900 x 1100 mm 47.2 x 35.4 x 47.2 in |

Travel Laser head: A |

180 ° |

Travel machine table: B |

720 ° |

Table dimensions |

800 mm 31.5 in |

Distance floor to table |

1030 mm 40.6 in |

Working area

Working area |

|

Max workpiece dimensions |

Ø 810 *** mm Ø 31.9 *** in |

Max workpiece machining height |

850 *** mm 33.5 *** in |

Max workpiece weight five axis |

1200 kg 2646 lbs |

Full five-axis dimensions |

Ø 560 x 710 *** mm Ø 22 x 28 *** in |

* Width x depth x height ** with FS163 *** with FS255 **** with FS340

CHARMILLES LASER S 2500 U

Main specifications

Main specifications |

|

Machine dimensions* |

6,420 x 3,573 x 3,687 mm 252.8 x 140.7 x 145.2 in |

Space required for installation |

7,125 x 6,304 x 3,804 mm 280.5 x 248.2 x 149.8 in |

Machine weight |

24,000 kg 52,911 lbs |

Focal length |

FS340 Type |

Ytterbium pulsed laser (Flexipulse) |

100 / 150 W |

| Ultrashort pulsed laser | 100 W Femto IR FD |

Electrical and pneumatic supply

Electrical and pneumatic supply |

|

Nominal power |

40 kVA |

Air pressure |

6 bar |

Required air output flow |

150 l/min |

Printing specifications

Printing specifications |

|

X, Y, Z travels |

2,500 x 2,000 x 1,200 mm 98.4 x 78.74 x 47.24 in |

Travel Laser head: A |

240 (-90/+150) ° |

Travel machine table: B |

370 (-185/+185) ° |

Table dimensions |

2,600 x 2,200 mm 102.4 x 86.6 in |

Distance floor to table |

600 mm 23.6 in |

Working area

Working area |

|

Max workpiece dimensions |

2,700 x 2,300 mm 106.3 x 90.5 in |

Max workpiece machining height |

1,340 mm 52.8 in |

Max workpiece weight |

10,000 kg 22,046 lbs |

Full five-axis dimensions |

Ø 750 x 1,340 **** mm Ø 29 x 52.8 **** in |

* Width x depth x height ** with FS163 *** with FS255 **** with FS340

Discover our CHARMILLES LASER S series videos

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Testimonials

Testimonial video - Zhejiang Jialong Sculpture

Testimonial Zhejiang Jialong Sculpture – About the CHARMILLES LASER S 2500 U.

"We are very happy to go forward with CHARMILLES and continue to develop a better future"

Please accept all cookies to view the youtube video content.

Testimonial video - Piazza Rosa

Testimonial Standex Engraving MOLD-TECH – Piazza Rosa about the CHARMILLES LASER S 1000 U.

"The LASER S will help to open again projects which were not feasible. [It will] enlarge application possibilities."

Please accept all cookies to view the youtube video content.

Testimonial video - Reichle

Testimonial REICHLE Technologiezentrum GmbH – about the CHARMILLES LASER S 1200 U.

" The LASER S will reduce leadtime, reduce the cost per parts […] it will open new business opportunities"

Please accept all cookies to view the youtube video content.

Testimonial video - Reichle

Testimonial REICHLE Technologiezentrum GmbH – about the CHARMILLES LASER S 2500 U.

"It is not just an evolution of Laser texturing, it is more a revolution of the existing technology"

Please accept all cookies to view the youtube video content.