- Clean and chatter-free leading and trailing edge quality

- Rigid machine design for ultra-dynamic Milling without vibration marks

- Tilted rotary table with high-acceleration, horizontal Spindle configuration for complete blisk machining in one setup

- Specialized TURBOSOFT plus CAM software for efficient programming and process optimization of blisks

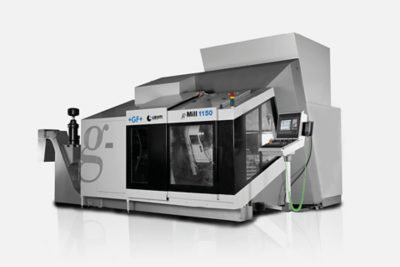

Liechti g-Mill series / go-Mill series

Please accept all cookies to view the external content.