Please accept all cookies to view the external content.

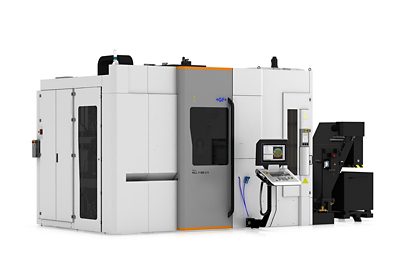

MILL P 500 U - MILL P 800 U (ST)

Please accept all cookies to view the external content.

MILL P 500 U

MILL P 500 U

MILL P 500 U

MILL P 500 U

- MILL P 500 U

- MILL P 500 U

MILL P 800 U S – The machine that grows with your needs

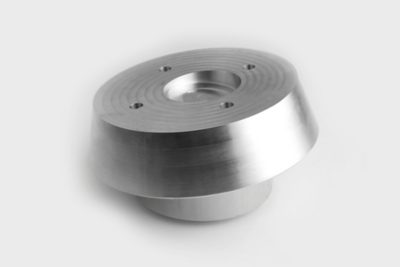

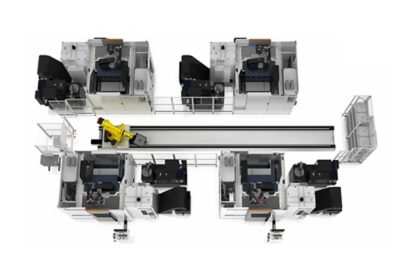

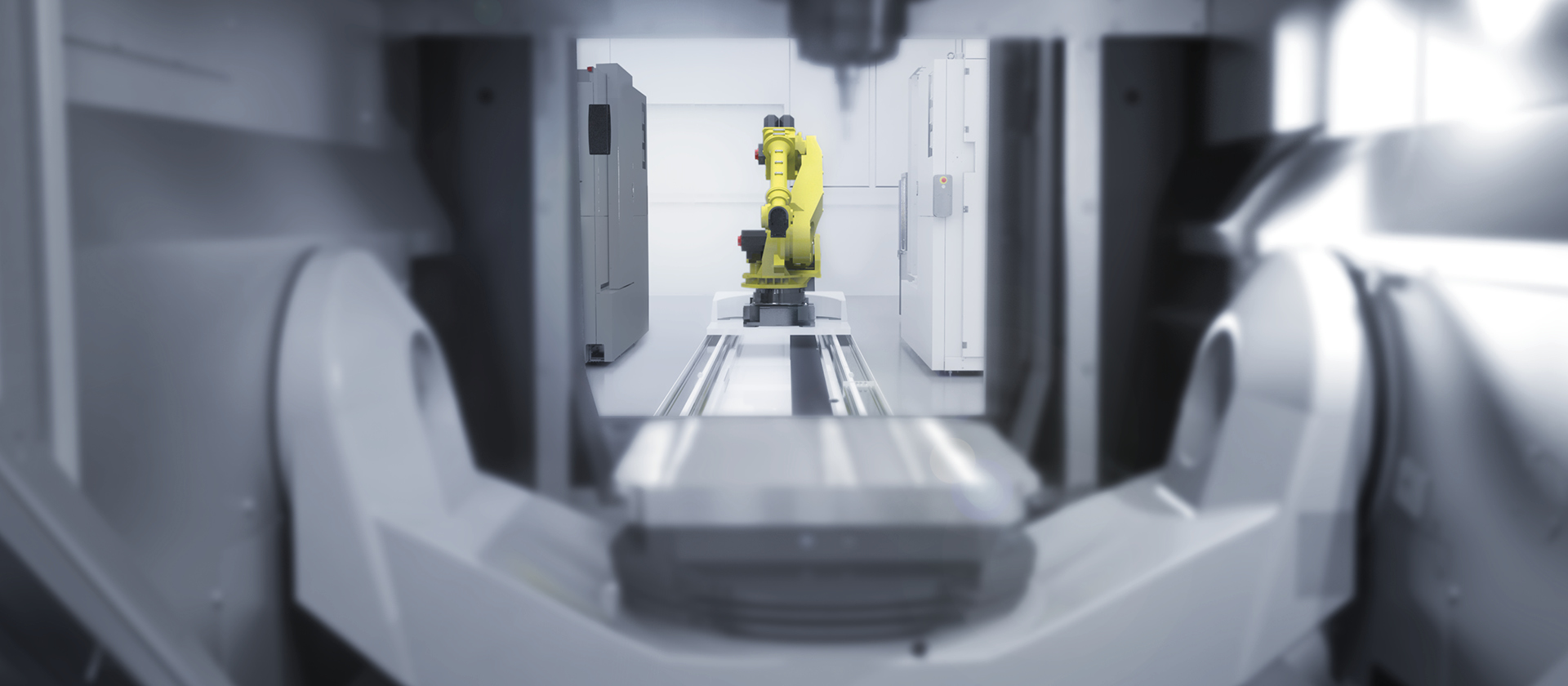

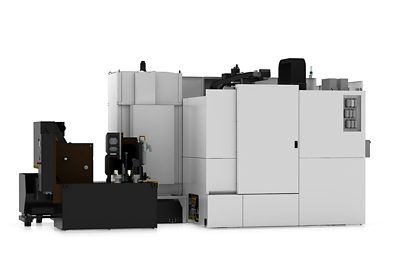

The Mikron MILL P 800 U S delivers intelligent productivity to help mold and die manufacturers overcome their daily challenges. Rapid market developments and future-changing innovations challenge mold and die manufacturers’ ability to adapt to change. UNITED MACHINING provides to these manufacturers its MILL P 800 U S five-axis, simultaneous Milling machines. The MILL P 800 U S is a very robust, stable and accurate machine center in a gantry-type design with limitless automation possibilities. This five-axis Milling solution is designed for high-performance machining applications. For best accuracy and surface finish by simultaneous operation, the machine has water-cooled direct drives in the rotary and swiveling axes. Thanks to its unique compact concept and its modularity, the machine ensures precise machining applications in both single item and fast, productive serial production.

The Mikron MILL P 800 U S delivers intelligent productivity to help mold and die manufacturers overcome their daily challenges. Rapid market developments and future-changing innovations challenge mold and die manufacturers’ ability to adapt to change. UNITED MACHINING provides to these manufacturers its MILL P 800 U S five-axis, simultaneous Milling machines. The MILL P 800 U S is a very robust, stable and accurate machine center in a gantry-type design with limitless automation possibilities. This five-axis Milling solution is designed for high-performance machining applications. For best accuracy and surface finish by simultaneous operation, the machine has water-cooled direct drives in the rotary and swiveling axes. Thanks to its unique compact concept and its modularity, the machine ensures precise machining applications in both single item and fast, productive serial production.

MILL P 800 U S

MILL P 800 U S

MILL P 800 U S

MILL P 800 U S

MILL P 800 U S

MILL P 800 U S

MILL P 800 U S

MILL P 800 U S

- MILL P 800 U S

- MILL P 800 U S

- MILL P 800 U S

- MILL P 800 U S

Sustainability

Discover our innovations that allow the Mikron MILL P U series to achieve low energy consumption in daily use as well as along your yearly production.

Please accept all cookies to view the external content.

Specifications

MILL P 500 U

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 500 x 600 x 450 mm |

| Feed rate X/Y/Z | 45 (61 dynamic version) m/min |

| Swivelling range | +91/-121° |

| Rotary range | n x 360 rpm |

| Feed rate swivel | 25 (50 dynamic version) rpm |

| Feed rate rotary | 35 (60 dynamic version) rpm |

| Working table | T-slot table Ø500 System 3R Dynafix / Delphin / Erowa UPC |

| Table load | 200 / 600 kg |

| Working spindle | 20'000 rpm - HSK-A63 |

| Tool magazine | 30 / 60 / Tool Tower 120 / 170 / 215 pockets |

| Footprint | |

| Automation | Pallet magazine 7 Dynafix / UPC Pallet magazine 5 Delphin System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

MILL P 800 U

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 800 x 800 x 550 mm |

| Feed rate X/Y/Z | 45 (61 dynamic version) m/min |

| Swivelling range | +91/-121° |

| Rotary range | n x 360 rpm |

| Feed rate swivel | 25 (50 dynamic version) rpm |

| Feed rate rotary | 35 (60 dynamic version) rpm |

| Working table | T-slot radial / parallel Ø630 mm T-slot radial / parallel Ø500 mm System 3R Delphin 400 x 400 / 500 x 500 / 500 x 630 mm |

| Table load | 500 / 1000 kg |

| Working spindle | 20'000 rpm - HSK-A63 |

| Tool magazine | 30 / 60 / Tool Tower 120 / 170 / 215 pockets |

| Footprint | |

| Automation | Pallet magazine 7x (500x630) Pallet magazine 9x (500x500) Pallet magazine 12x (400x400) System 3R Workpartner 1+, Transformer WorkMaster & Transformer 6-axis |

MILL P 800 U ST

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 800 x 800 x 550 mm |

| Feed rate X/Y/Z | 61 m/min |

| Swivelling range | +91/-121° |

| Rotary range | n x 360 rpm |

| Feed rate swivel | 50 rpm |

| Feed rate rotary | 100 milling / 800 Simultaneous Turning rpm |

| Working table | T-slot table radial Ø 730 / Ø 500 mm System 3R Delphin 400 x 400 / 500 x 500 / 500 x 630 mm |

| Table load | 800 kg |

| Working spindle | 20'000 rpm - HSK-T63 |

| Tool magazine | 30 / 60 / Tool Tower 120 / 170 / 215 pockets |

| Footprint | |

| Automation | Pallet magazine 7x (Ø730) Pallet magazine 9x (Ø500) Others on request |

MILL P 800 U S

Main Specifications

Main Specifications |

|

| Travel X, Y, Z | 800 x 800 x 500 mm |

| Feed rate X/Y/Z | 61 m/min |

| Swivelling range | +91/-121° |

| Rotary range | n x 360 rpm |

| Feed rate swivel | 25 rpm |

| Feed rate rotary | 35 rpm |

| Working table | System 3R Delphin 500 x 500 mm |

| Table load | max. 1000 kg |

| Working spindle | 20'000 rpm - HSK-A |

| Tool magazine | Tool Tower 170 pockets |

| Footprint | |

| Automation | System 3R Transformer 6-axis Others on request |

Discover our videos

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.

Please accept all cookies to view the youtube video content.