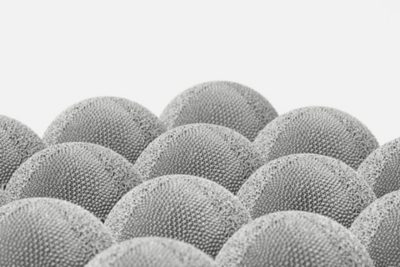

Knee implant

Manufacturing the femoral component for knee implants presents significant challenges. Achieving precise curvature and smoothness on the condyle surfaces requires adherence to strict tolerances. GF Machining Solutions, in collaboration with Seco and OpenMind, devised an innovative milling approach by using the 5-axis Mikron MILL S 600 U, specialized cutting tools and a custom CAM program. This unique collaboration allowed:

- Reducing the overall machining time

- Eliminating the need for grinding

- Enhancing surface roughness