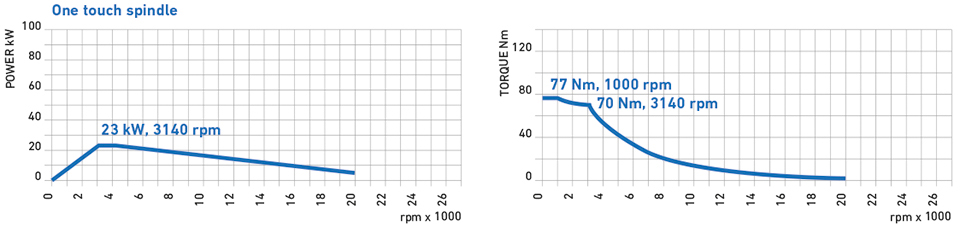

Step-Tec HPC 190 - One Touch

Dimensions / weight

ø190 x 656 mm / 89 kg

| Dimensions / weight | ø190 x 656 mm / 89 kg |

| Speed (nmax) | 20’000 rpm |

| Torque S1 / S6 40% | 77 / 120 Nm |

| Power S1 / S6 40% | 23 / 36 kW |

| Interfaces | SK 40, HSK A/C/T 63, HSK F 80 |

| Through Spindle Coolant | O, H2O, oil, Co2, MQL |

| Lubrification | oil-air / grease |

| Cooling | OptiCool |

| Sensors | Encoder, Tool Position Monitoring, Temperature, Vibration, axial expansion (option) |

| Mill-Turn function | Interlock (SSL) 500 Nm |

| Software (options) | Spindle Diagnostic Software, Spindle Monitoring Software |

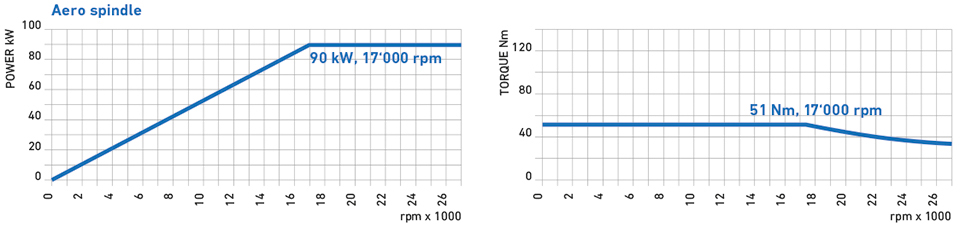

Step-Tec HPC190 - Aero

Dimensions / weight

ø190 x 630 mm / 85 kg

| Dimensions / weight | ø190 x 630 mm / 85 kg |

| Speed (nmax) | 27’000 rpm |

| Torque S1 / S6 40% | 51 / 64 Nm |

| Power S1 / S6 40% | 90 / 114 kW |

| Interfaces | HSK A/ 63, HSK F 80 |

| Through Spindle Coolant | O, H2O, oil, Co2, MQL |

| Lubrification | oil-air |

| Cooling | OptiCool |

| Sensors | Encoder, Tool Position Monitoring, Temperature, Vibration, axial expansion (option) |

| Software (options) | Spindle Diagnostic Software, Spindle Monitoring Software |