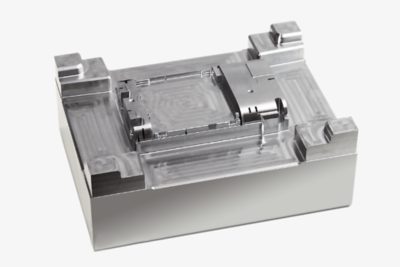

Device cover injection mold

GF Machining Solutions' Laser texturing technology prepares injection molding surfaces for mobile phone, laptop and other consumer electronics covers with unmatched performance. The ease of solution empowers designers to create unique textures and improve the consumer experience and comfort. Our Laser technology enables mold manufacturers to realize aesthetic and functional design for light diffraction, anti-scratch, anti-slip and many more:

- Create fully digital functional textures with 100% repeatability

- Use a single setup for texturing, engraving and marking operations

- Substitute manual time-consuming etching processes with laser

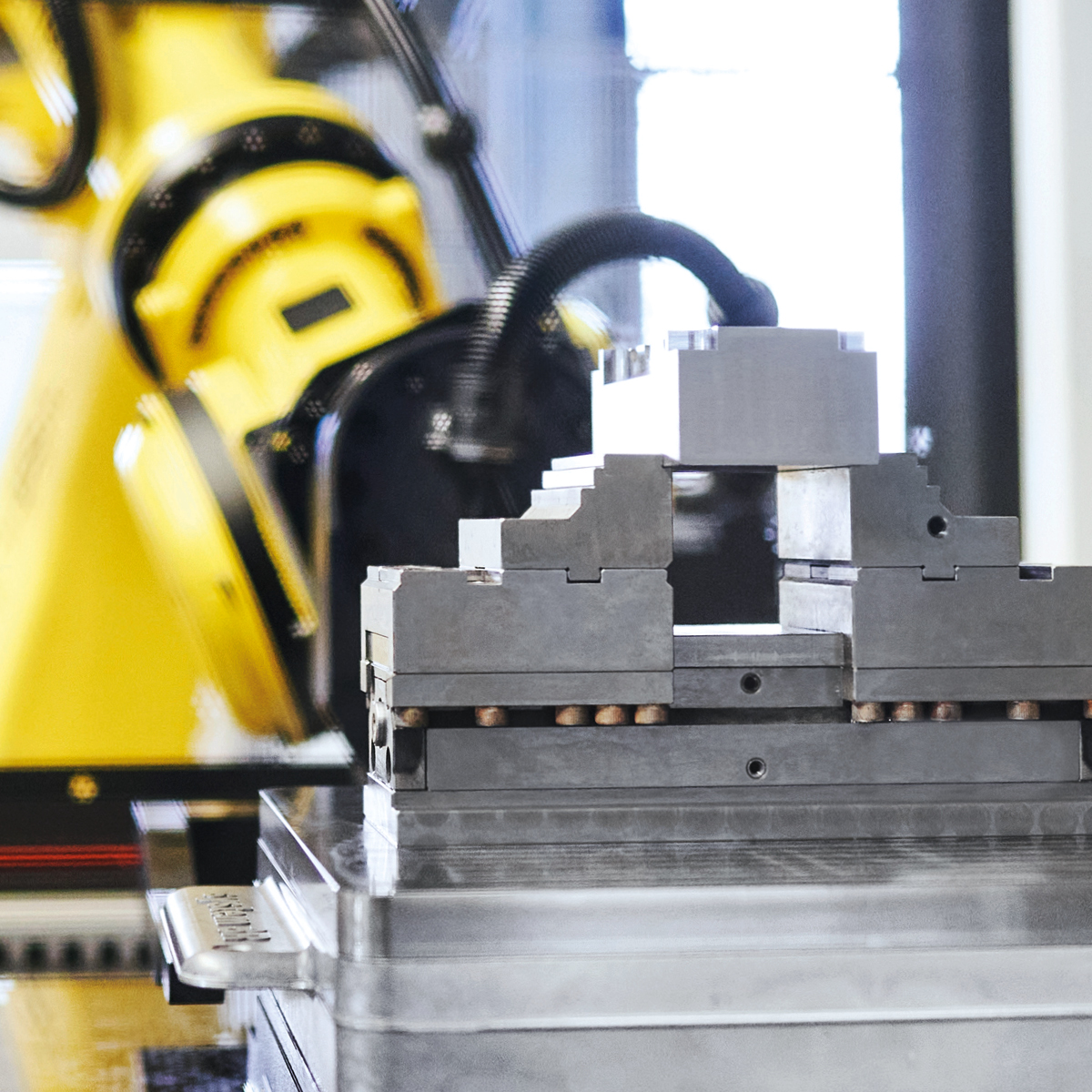

Plastic assembly components injection mold

Mobile devices contain multiple plastic components to ensure perfect assembly and functioning. The components contain multiple micro-slots, thin insert walls that present challenging mold tool manufacturing constraints. With our Die-sinking EDM product line manufacturers achieve perfect quality and production control on rib machining, micro features, reinforcement features which are an integral part of device realization:

- Achieve the desired surface finish on the mold surface

- Use copper or graphite electrode erosion technology

- Machine features with greater details

- Save electrode cost by optimizing the die-sinking process

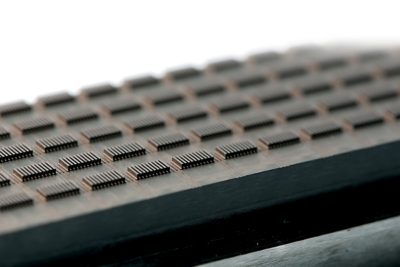

Electrode machining for injection mold insert

The development of molds for mobile devices requires large numbers of electrodes, multiple shapes for the creation of cavities with Die-sinking EDM. Our dedicated graphite electrode Milling solution allows the exact realization of such electrodes with great details:

- Faster machining process with high spindle speed (42'000 rpm) and highly dynamic (61 m/min) machining

- Safe graphite machining with integrated graphite dust suction

- High surface finish with Ra 0.4 µm without marks

- Tool clamping HSK E-40 to machine electrodes with small cutters

Graphite mold for smart device screens

Nowadays glass surfaces for user interfaces are facing innovation challenges such as miniaturization, embedded functionalities and demand for high strength. Our graphite Milling solution empowers manufacturers to create graphite mold inserts for glass molding and achieve their technical and business needs:

- Achieve the best surface finish fitting 3D glass mold requirements

- Guarantee long-term accuracy necessary for mold manufacturing

- Automate the process with WPC and S3R pallets

- Ensure production safety with integrated graphite dust evacuation systems