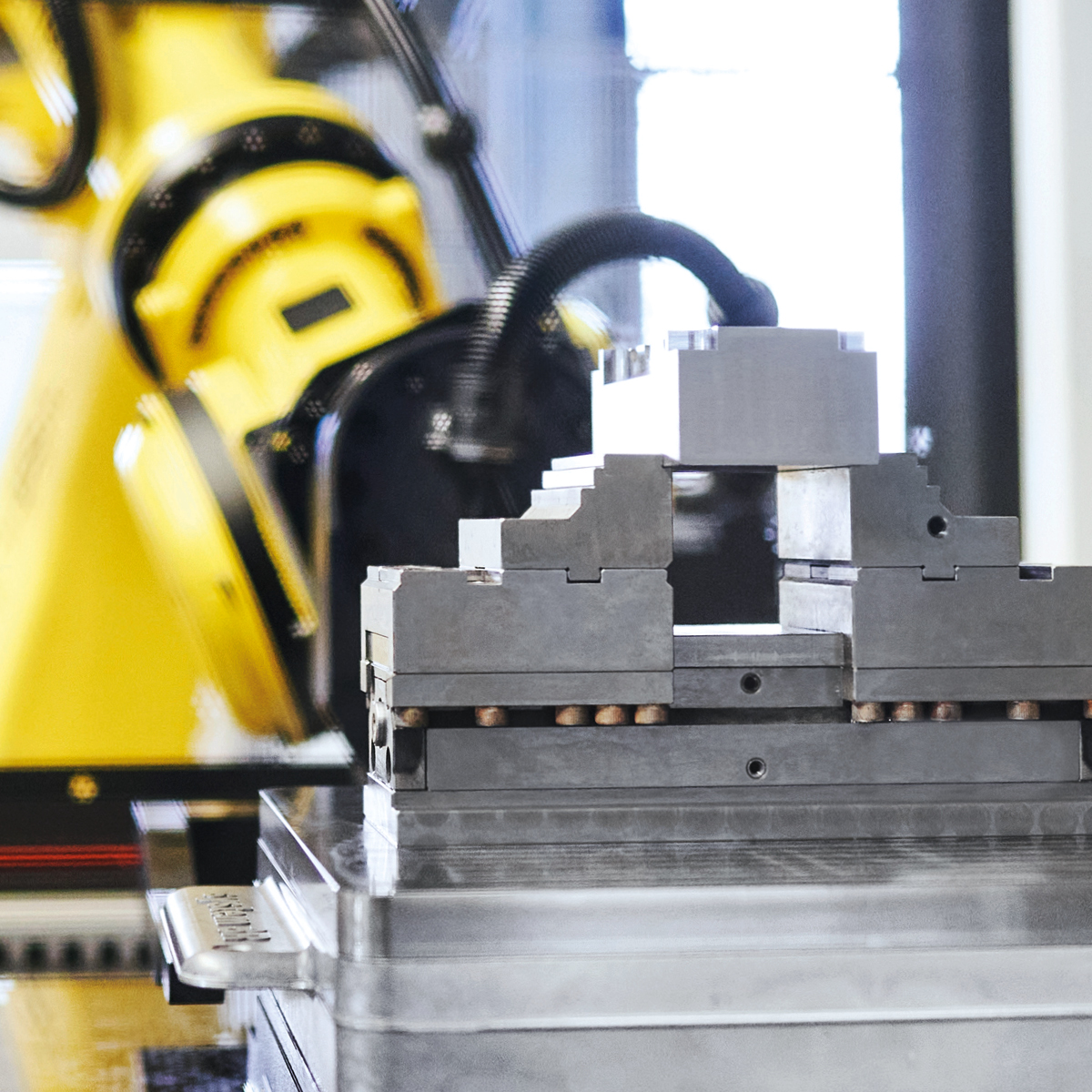

Complex cavity mold insert

Our 5-axis high-speed Milling and Laser ablation technologies combine to manufacture three-dimensional complex mold cavities for extended quality and productivity. With the MILL S 600 U and the LASER S 1000 U, achieve:

- Higher removal rates and greater contour accuracy

- Single setup production and reduced tooling cost

- Digital process for complete repeatability

- Ability to design and texture complex cavity without quality loss

- Uniform texture flow without patch lines

Texturing mold insert cavity

Our unique 5-axis Laser solution enables texturing of mold cavities to create aesthetic designs on packaging. The Laser S 1000 U allows:

- Increased productivity and texture quality with Smartpatch

- Continuous texture without patch line on three-dimensional surfaces

- The ability to machine a variety of mold tool material for plastic, glass, resin processing

Functional texturing on mold cavity surfaces

Packaging needs multiple functionalities such as low-gloss, high-gloss, anti-slip, gripping, light diffraction, polishing, clarity. With our LASER S 1000 U such functionalities can be directly achieved on mold surfaces:

- Digitally-controlled laser parameters and grain size

- Full-digital processes for extended repeatability of designed textures

- Eliminate environmentally harsh techniques such as etching, glossing on mold and injected plastic