GF Machining Solutions helps you prepare for the challenges of unprecedented aerospace industry growth with a competitive business model and cost management.

Discover our expertise in aerospace

Our Aerospace technologies

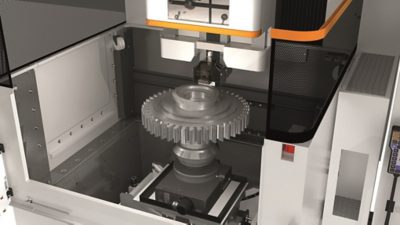

Our optimized solutions to machine fir-tree slots on turbine disks

Highly precise part positioning with the chuck MATRIX of System 3R in the CUT 200 Dedicated

Highly precise part positioning with the chuck MATRIX of System 3R in the CUT 200 Dedicated

- Discover GF Machining Solutions complete solution dedicated to fir-tree slots on turbine disks.

- CUT 200 Dedicated : digital EDM technology for minimum heat-affected layer and maximum speed

- This solution uses the special Wire VH 025

- eTracking : EDM software allowing real time quality monitoring and data traceability

- Highly precise part positioning with the chuck MATRIX of System 3R in the CUT 200 Dedicated

- GF Machining Solutions' Customer Services offer a support to the Nadcap accreditation

1/