The challenges and the solution

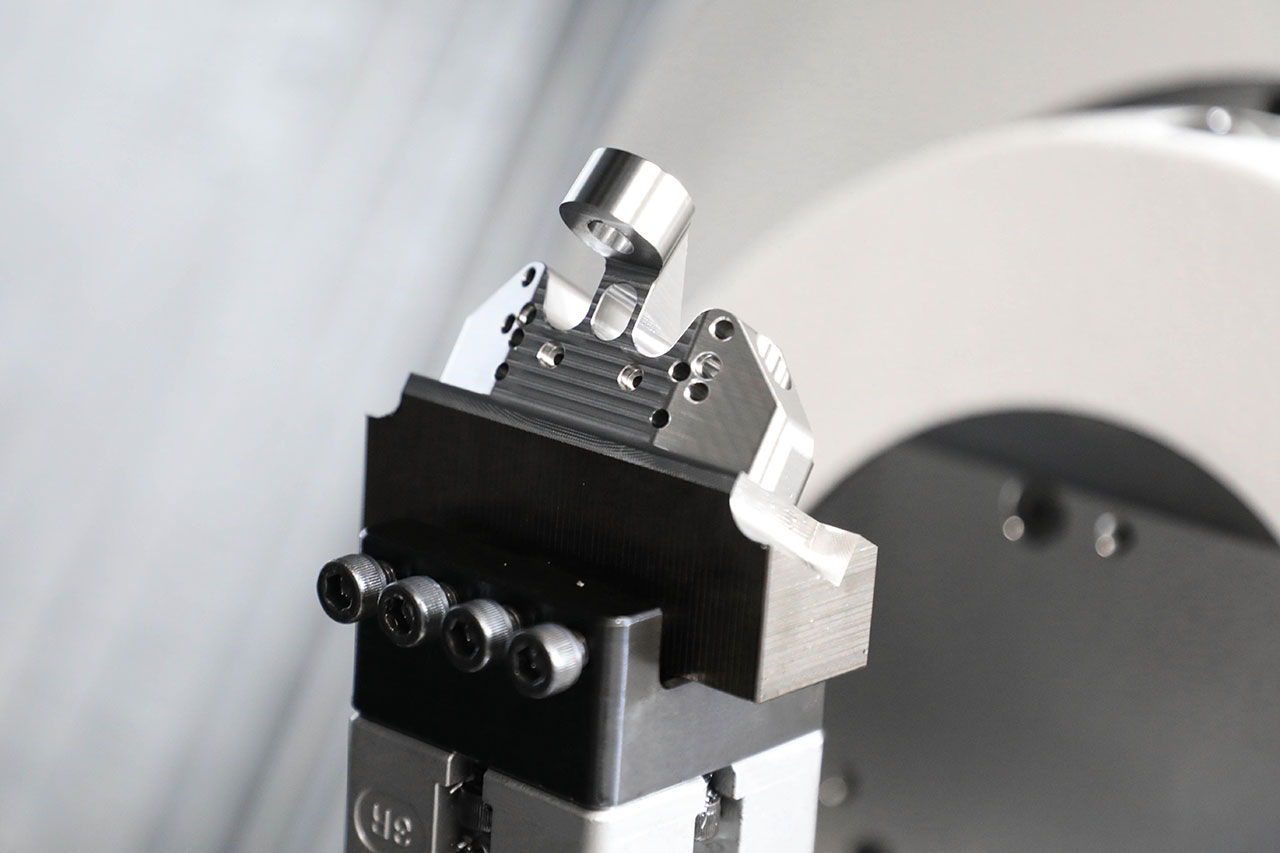

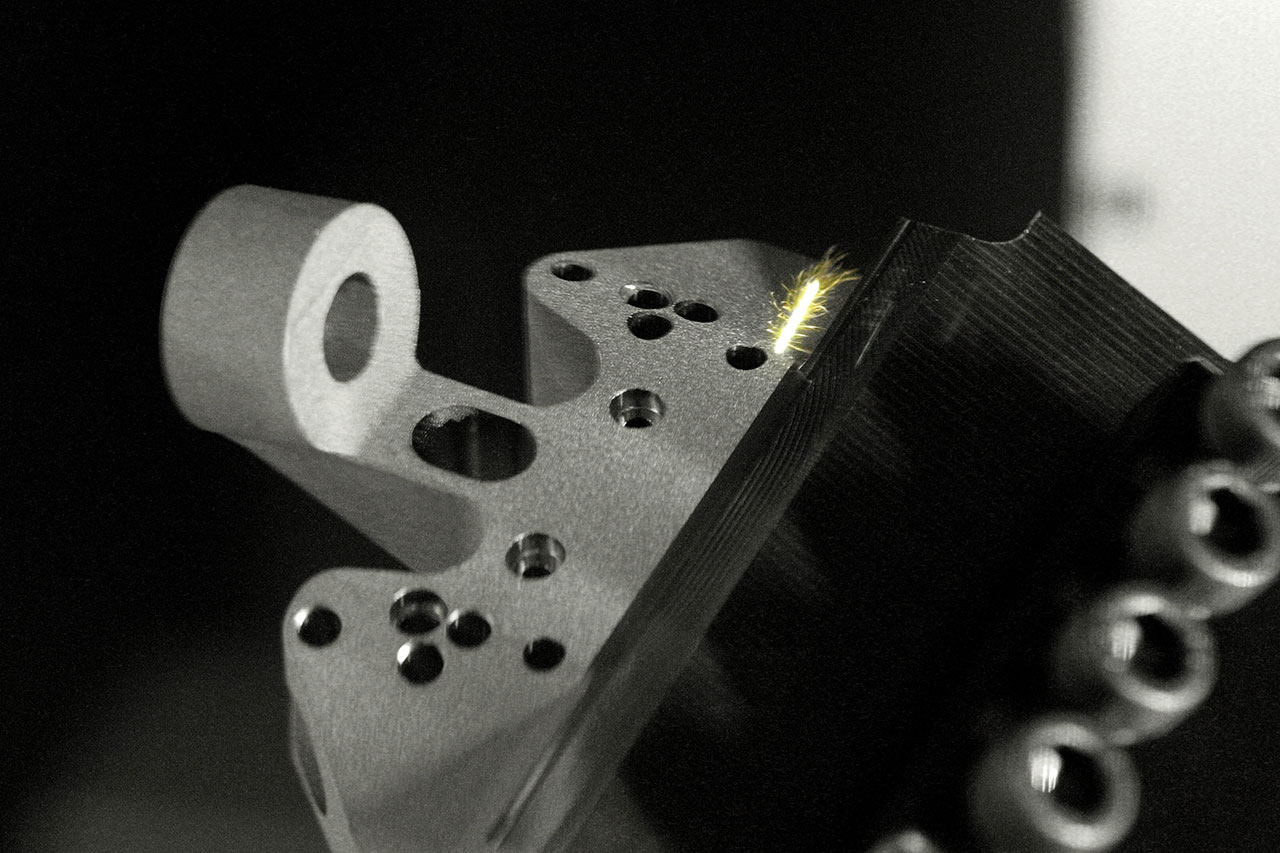

Bone Saw Guide Blocks are a good example of challenging medical devices. Traditionally, their manufacture requires milling, wire EDM, grit or sand blasting, laser marking and polishing. With many associated challenges:

- The need for a high quality surface finish and high tolerances during milling;

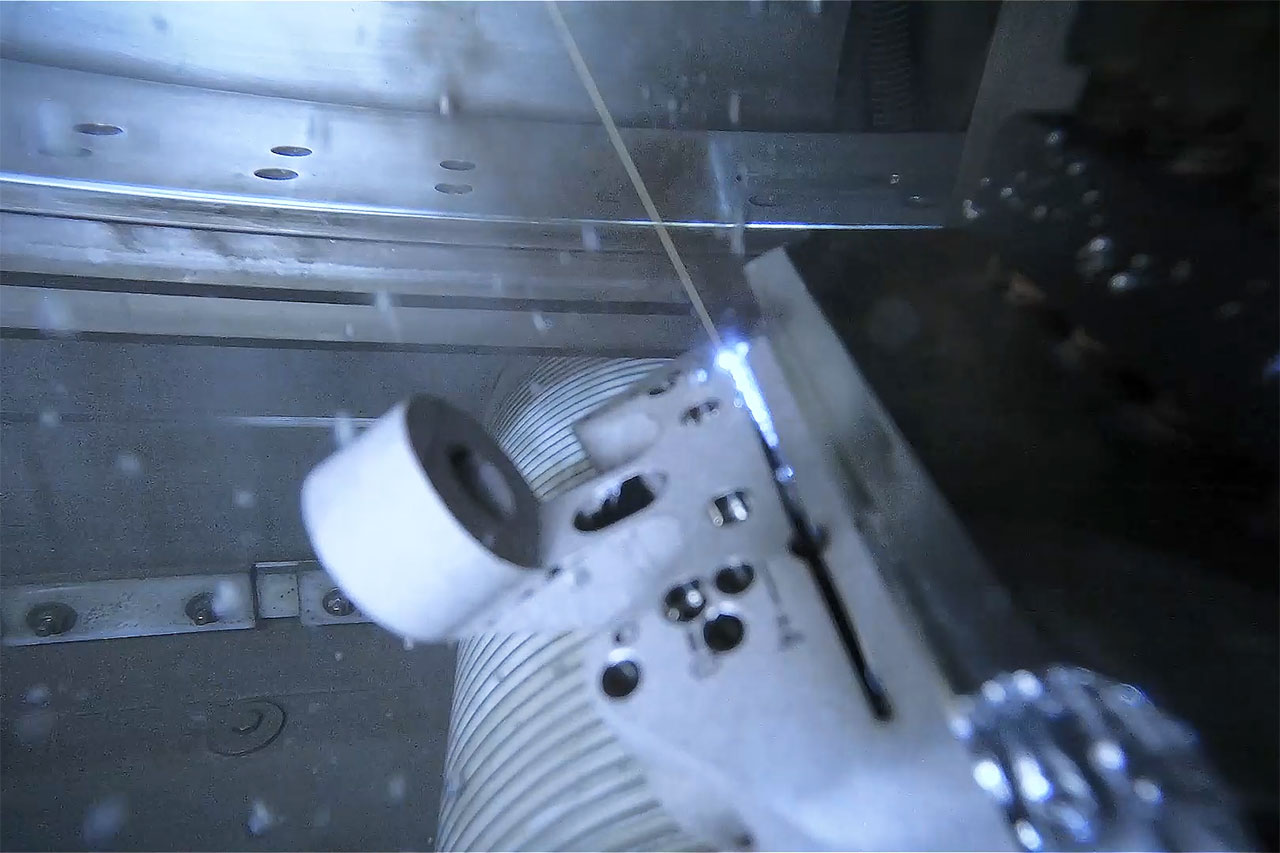

- the risk of wire breakage and quality problems during EDM;

- the risks and costs of manual operations – including for sand or grit blasting;

- last but not least, the challenge to track key manufacturing information to meet regulatory needs.

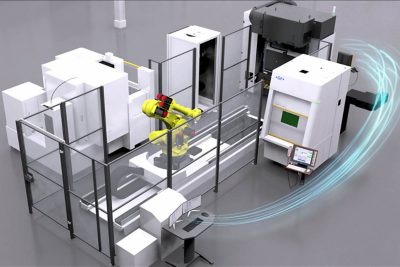

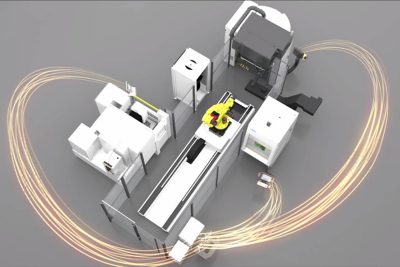

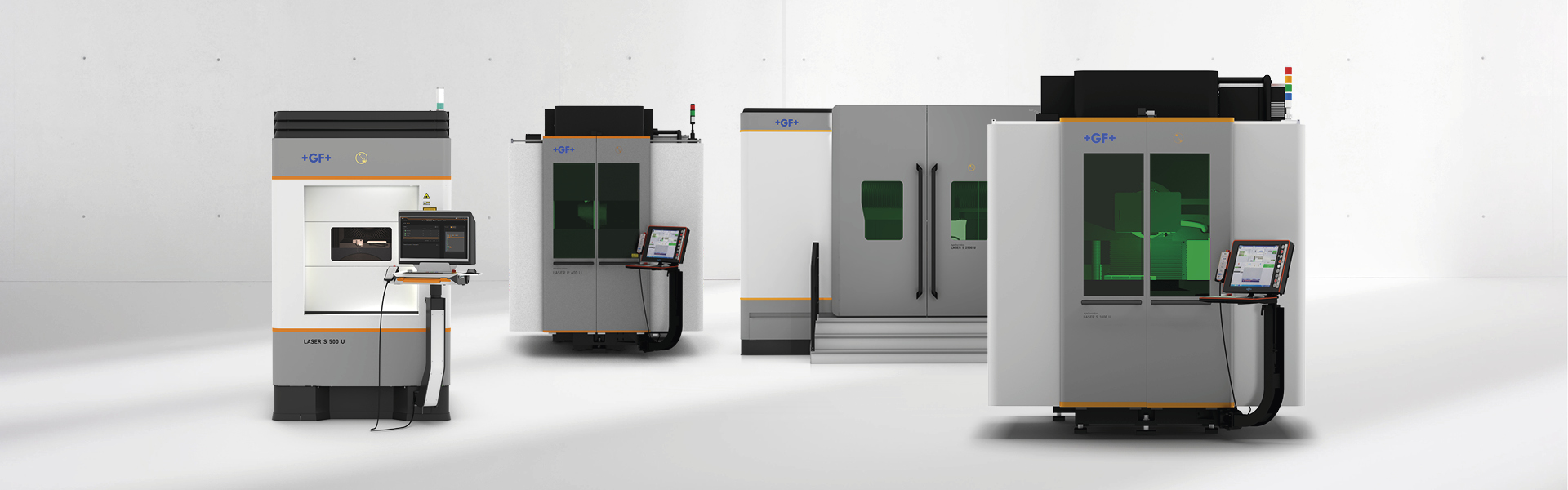

GF Machining Solutions' fully automated and integrated cell including milling, wire EDM, Laser texturing, automation and intelligent tooling and software, helps you meet all these challenges and ensures a better data tracking along the process, from and back to the factory resource planning system (ERP).