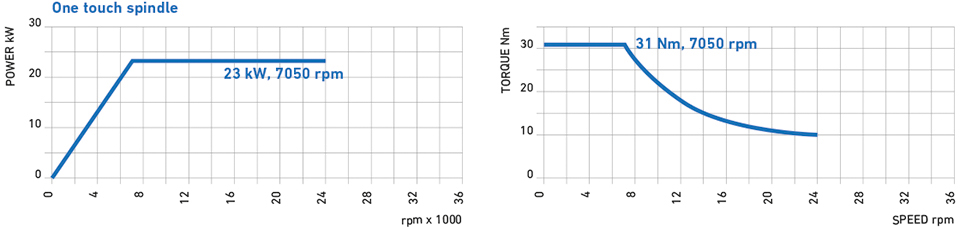

Step-Tec HVC/HPC 150 - One Touch

Dimensions / weight

ø150 x 579 mm / 55 kg

| Dimensions / weight | ø150 x 579 mm / 55 kg |

| Speed (nmax) | 24’000 rpm |

| Torque S1 / S6 40% | 31 / 41 Nm |

| Power S1 / S6 40% | 23 / 30 kW |

| Interfaces | HSK A/C/ 63, HSK F 80 |

| Through Spindle Coolant | O, H2O, oil, MQL |

| Lubrification | oil-air |

| Cooling | OptiCool, Option: CoolCore (Shaft cooling) |

| Sensors | Encoder, Tool Position Monitoring, Temperature, Vibration, axial expansion (option) |

| Software (options) | Spindle Diagnostic Software, Spindle Monitoring Software |

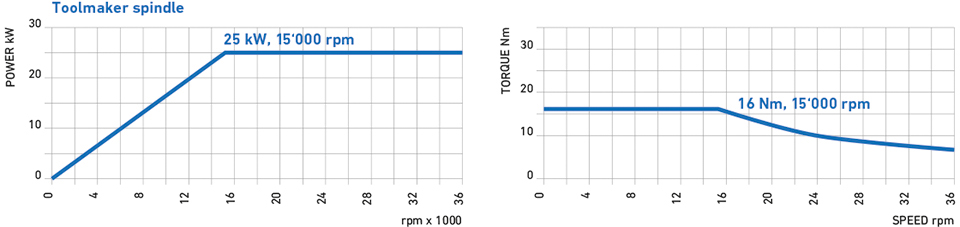

Step-Tec HVC/HPC 150 - Tool Maker

Dimensions / weight

ø150 x 468 mm / 40 kg

| Dimensions / weight | ø150 x 468 mm / 40 kg |

| Speed (nmax) | 36’000 rpm |

| Torque S1 / S6 40% | 16 / 21 Nm |

| Power S1 / S6 40% | 25 / 33 kW |

| Interfaces | HSK C/E 50, HSK F 63 |

| Through Spindle Coolant | O, H2O, oil, MQL |

| Lubrification | oil-air |

| Cooling | OptiCool, Option: CoolCore (Shaft cooling) |

| Sensors | Encoder, Tool Position Monitoring, Temperature, Vibration, axial expansion (option) |

| Software (options) | Spindle Diagnostic Software, Spindle Monitoring Software |

Industries

Please accept all cookies to view the external content.